Dry land ridge row ditcher

A ditching machine and dryland technology, which is applied in the field of ridges and ditching machines in dryland, can solve the problems of large workload of manual ridges and ditching, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, further description will be given to the ridge row ditching machine.

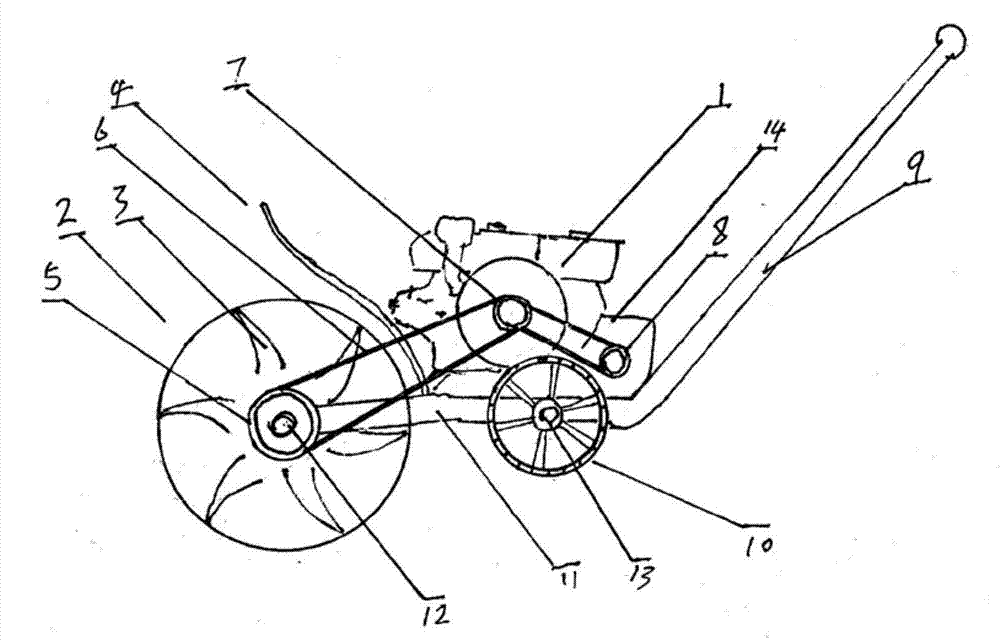

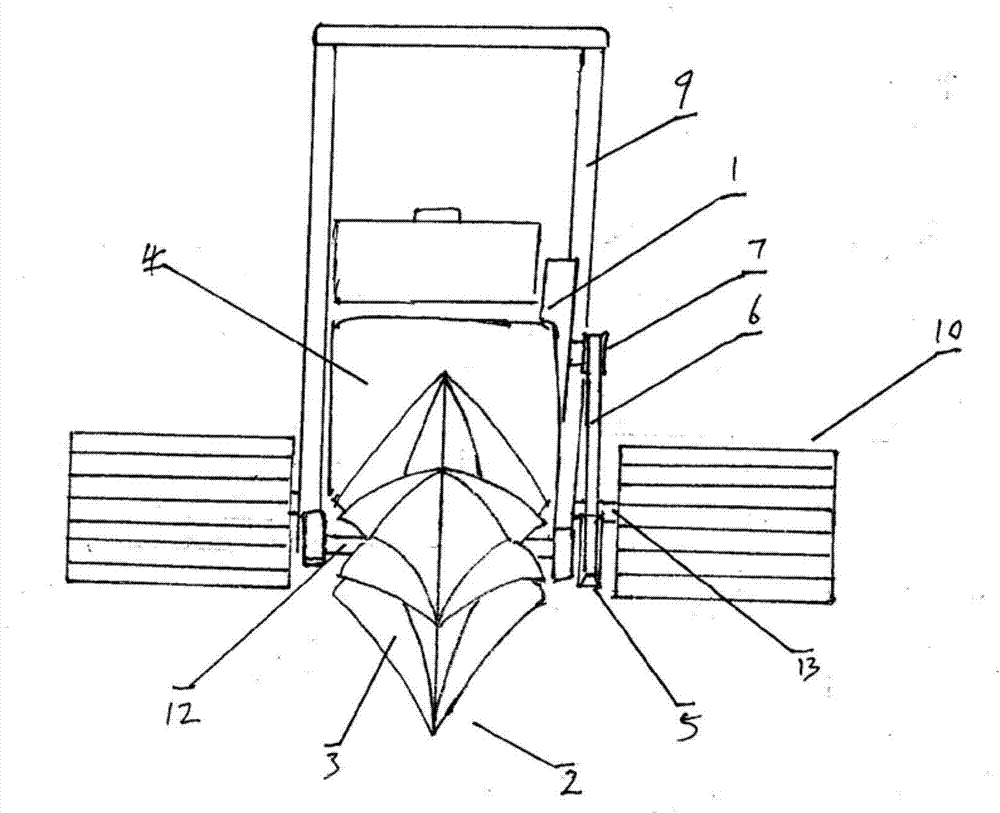

[0012] figure 1 It shows the side shape of a row trencher. This is a small two-wheel walking ridge ditching machine that is supported by human hands and supports walking. The two wide-side walking wheels (10) support the fuel engine (1) on the upper part of the connecting bracket (11), and the front one The wheel-shaped structure is the main device of the front-end work of the row ditching machine: the ditching runner (2). The ditching runner (2) is fixed by the rotating shaft (12) on the front end of the connecting bracket (11), and there is a large pulley (5) on its side through the belt (6) and the small pulley (7) on the fuel engine (1). ) for the power transmission relationship. The dry land ridge trenching machine adopts the transmission form of belt and pulley, which can only cause the belt to slip when the working device encounters a har...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com