Cross-coil used in dye column and device for manufacturing the coil

A cross-winding, dyeing column technology, applied in the direction of transportation and packaging, thin material handling, conveying filamentous materials, etc., can solve problems such as being unsuitable for dyeing treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

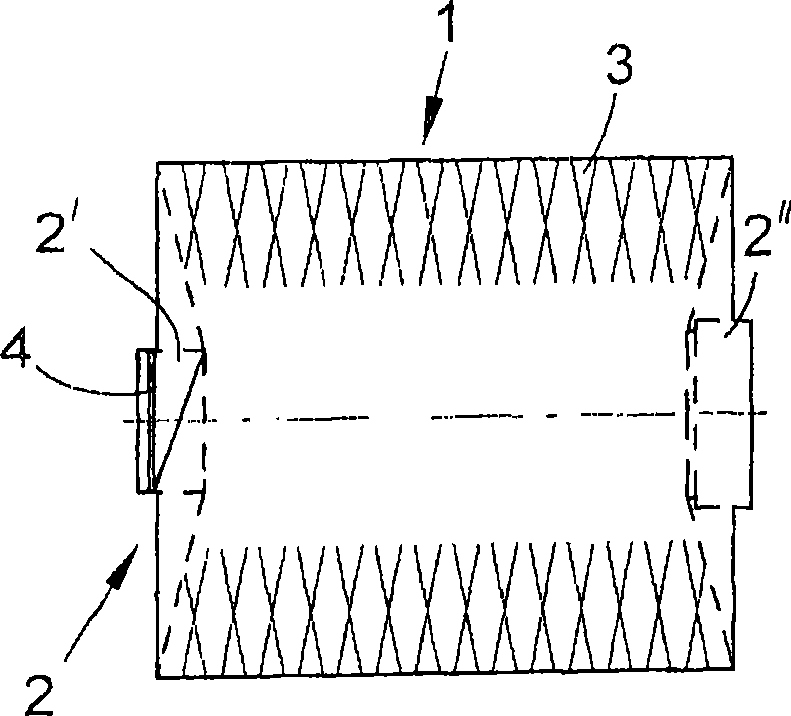

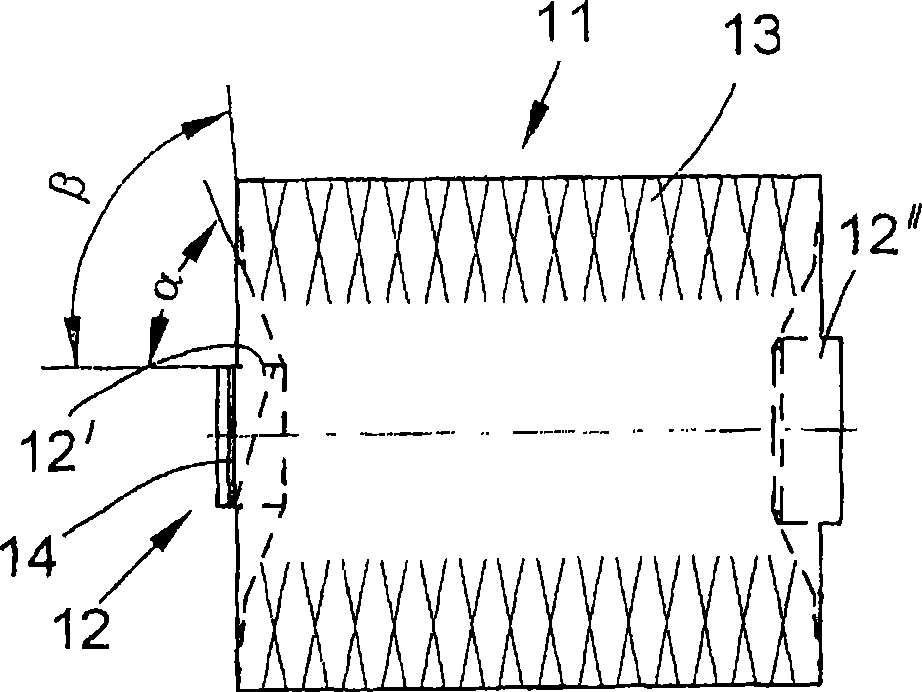

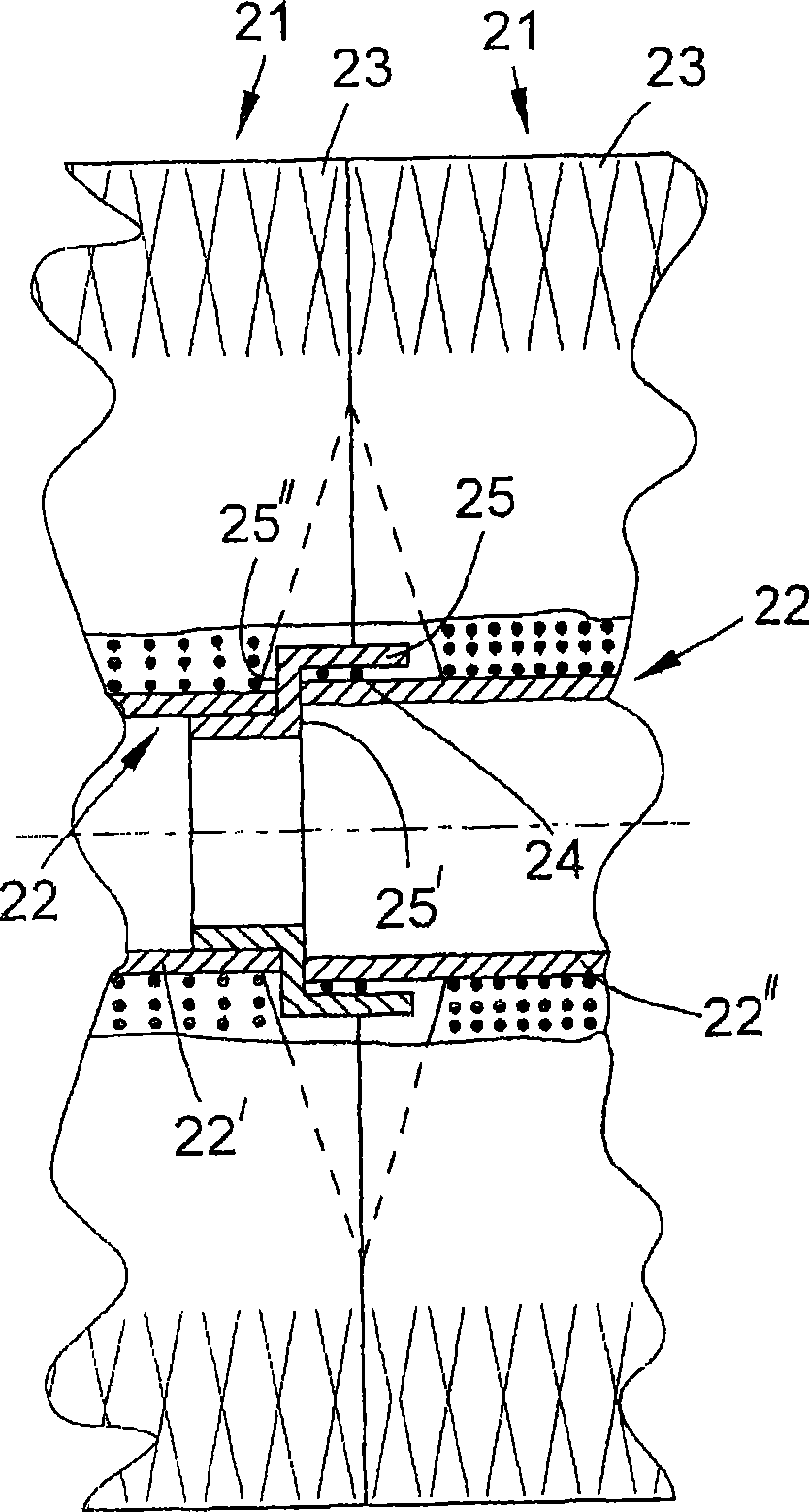

[0031] figure 1 The illustrated cross-wound bobbin 1 according to the invention for dyeing comprises a tube 2 and a cross-wound wire 3 . The tube 2 has corresponding holes in a form not shown here in order to transfer the dye liquor in the dye column from the tube to the winding wire 3 of the cross-winding drum. Furthermore, the cross-winding bobbin 1 has an end winding 4 on the tube end 2', which is provided for subsequent processing, for example for connecting the yarn starting ends of subsequent bobbins. In addition, it can be seen that the diameter of the tube end 2' is smaller than the diameter of the opposite tube end 2". When forming a staining column, the small diameter and the large diameter are always directly abutted against each other. Here, the side of the small diameter enters the large within the diameter of the pipe. The difference between the outer diameter of the small pipe end 2' and the inner diameter of the large pipe end 2" is large, so that the annular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com