Combospin Negative Pressure Air Concentration Mechanism

A combo spinning and air flow technology, applied in spinning machines, textiles and papermaking, drafting equipment, etc., can solve the problems of difficult cleaning of connectors, affecting production efficiency, large negative pressure loss, etc. The cleaning operation is convenient and the effect of reducing negative pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

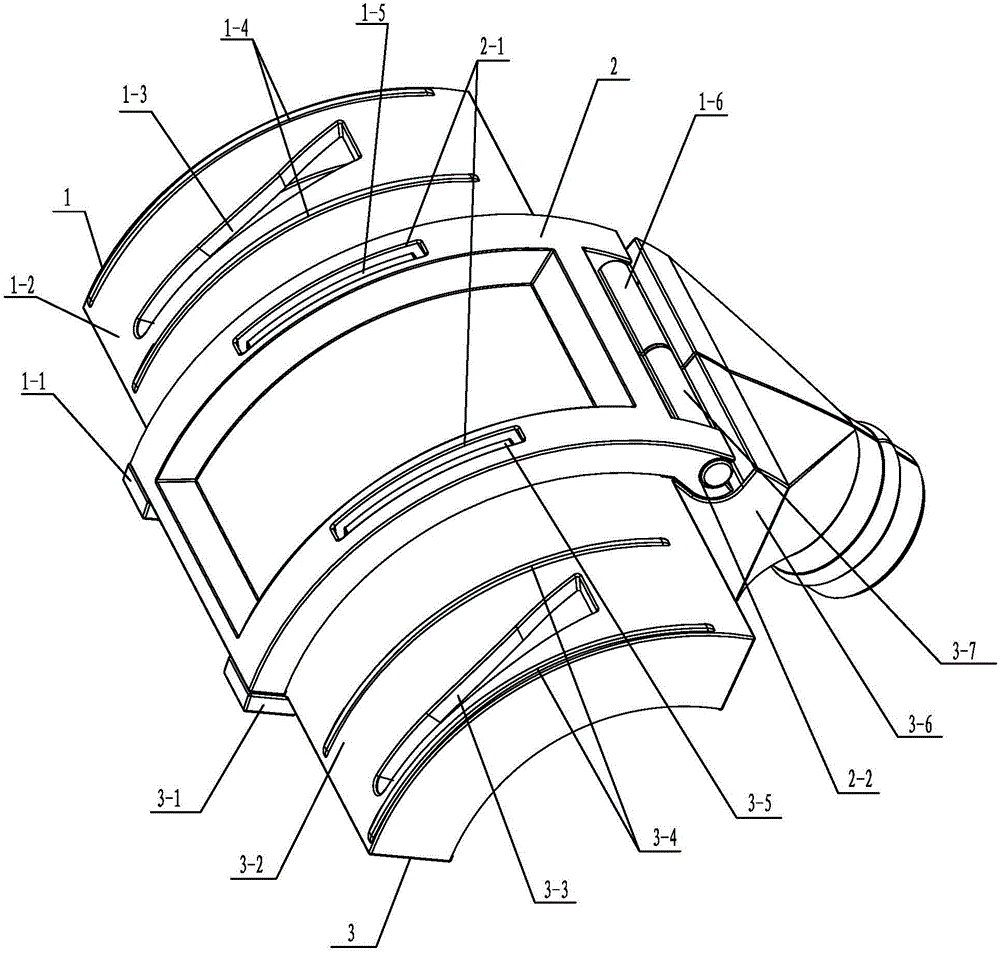

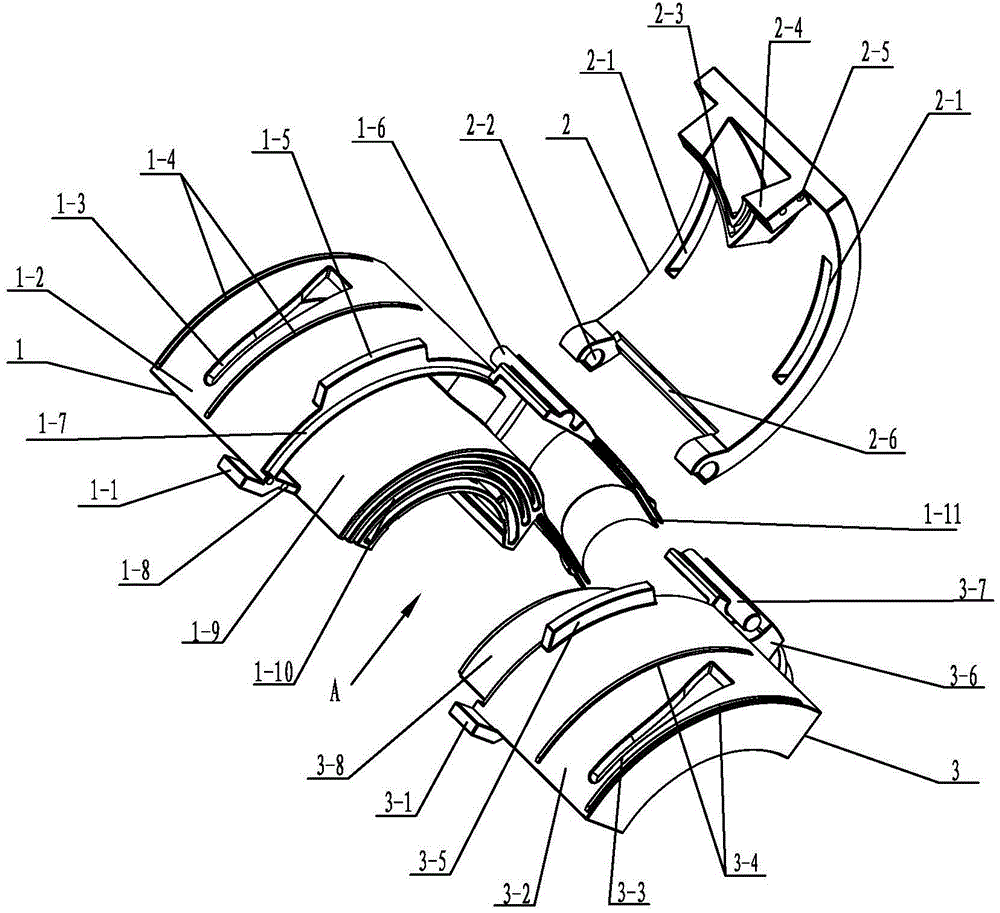

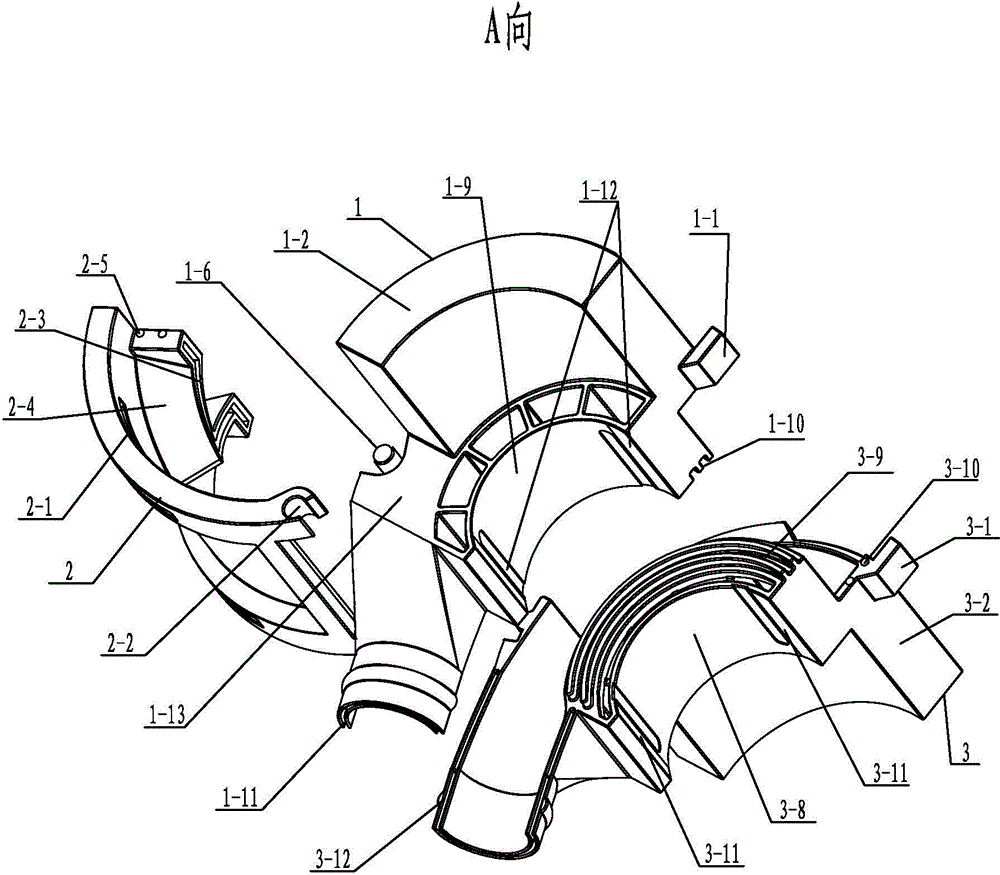

[0013] See Figure 1~3 As shown, the Comforspin negative pressure air gathering mechanism of the present invention includes a left air gathering part 1 , a right air gathering part 3 and a cover plate 2 .

[0014] See Figure 1~3 As shown, the left air flow collection part 1 of the present invention includes an arc-shaped left base 1-9, a left cover 1-2 with an air cavity inside and a left cover 1-9 integrated with the left base 1-9, and the top of the left cover 1-2 There is a left collecting groove 1-3 communicating with the air cavity, and the right air flow collecting part 3 includes an arc-shaped right base 3-8 and a right cover body 3-8 with an air cavity inside which is integrated with the right base 3-8. 2. The top of the right cover body 3-2 is provided with a right accumulating groove 3-3 connected with the air cavity, and the left whisker sticks to the left accumulating groove 1-3 through the airflow in the air cavity of the left cover body 1-2 At the same time, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com