Patents

Literature

30results about How to "Reduce negative pressure loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

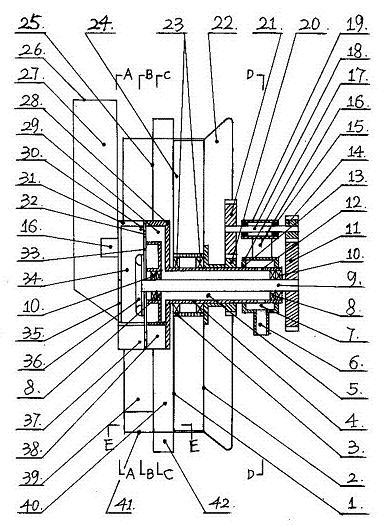

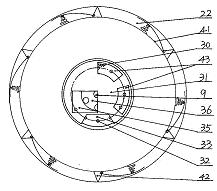

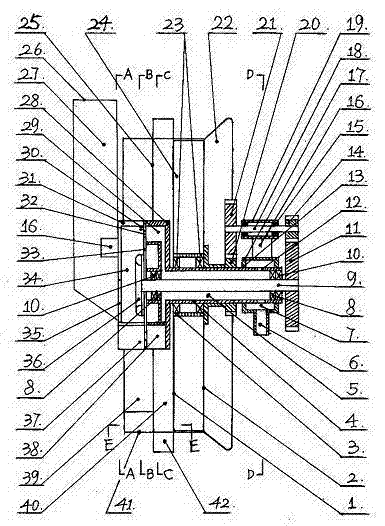

Suction type precision seed bunch planting device

InactiveCN101766078ALarge internal spaceIncrease heightSeed depositing seeder partsRegular seed deposition machinesAgricultural scienceAgricultural engineering

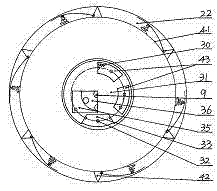

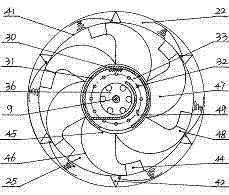

The invention relates to an agricultural seeding device, in particular to a suction type precision seed bunch planting device. The suction type precision seed bunch planting device mainly comprises a seed tank (26), a suction type seed sorter, a roller, a negative pressure air suction pipe (6), a speed shifting mechanism and a seed receiving and delivering device, wherein the suction type seed sorter is arranged in the roller and communicated with the negative pressure air suction pipe (6); a seed delivering box (47) is arranged between a seed outlet of the suction type seed sorter and a duck nozzle (42); a main shaft (4) of the roller is a hollow pipe; a main shaft (9) of the suction type seed sorter is arranged in the hollow pipe-shaped main shaft (4) of the roller; one end of the main shaft (9) of the suction type seed sorter is coupled to the suction type seed sorter through a bearing (8.1) and drives a seed suction disk (33), and the other end of the main shaft (9) of the suction type seed sorter passes through a sealing bearing (8) in the main shaft (4) of the roller; the main shaft (4) of the roller and the main shaft (9) of the suction type seed sorter are in speed-shifting connection through a gear or a chain or a notched belt. The suction type precision seed bunch planting device has the advantages of increasing the inner space of the roller as much as possible, increasing the height of the seed delivering box simultaneously, conveniently regulating the rotating speed ratio of the roller to the seed absorption box according to the agronomic requirements, and greatly improving the seeding speed while seeding accurately. Due to the unique transmission structure, the suction type precision seed bunch planting device is compact and steady, and the fault rate is reduced obviously under the environment of worse working condition.

Owner:陈恒

Method for improving stability of permanent gas extraction system of outburst mine

InactiveCN105525941AReduce Waterlogging ProblemsReduce the frequency of wateringDrainageGas removalSystem stabilitySlurry

The invention discloses a method for improving the stability of a permanent gas extraction system of an outburst mine. The method comprises a solution to water accumulation in a pipeline of the permanent gas extraction system, a solution to hole collapse occurring when drilling is carried out on a low-permeability soft coal seam, a solution to blockage of an extraction pipe due to excessive slurry, and a solution to gas leakage and abnormal negative pressure of the pipeline of the extraction system. By means of the method, the probability of water accumulation of the pipeline is reduced, and the extraction effect is improved; moreover, the phenomena of gas emission and hole collapse can be effectively avoided, and the situation that the gas cannot be extracted due to the fact that the extraction pipe is blocked by slightly excessive slurry is avoided; the stability and integrity of the permanent gas extraction system of the outburst mine are improved.

Owner:HUNAN UNIV OF SCI & TECH

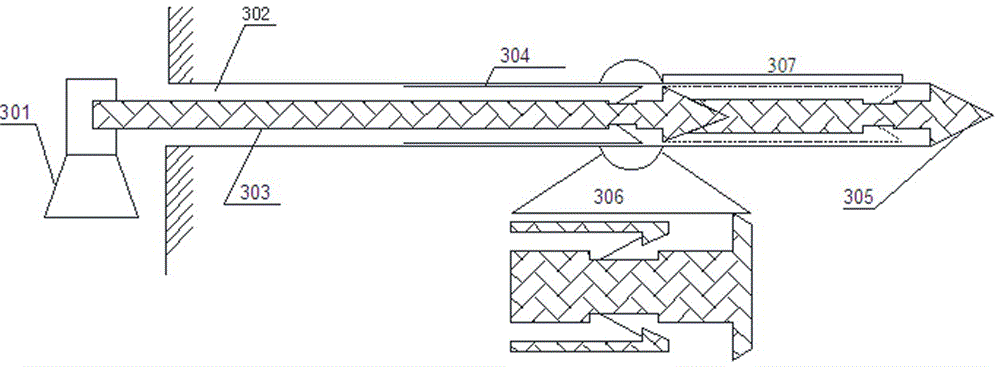

Method for cutting a string-shaped food and cutting machine

InactiveCN101518909AIntegrity guaranteedImprove sealingWork holdersMetal working apparatusContact elementDuring feed

The invention relates to a method for cutting string-shaped food, wherein the string shaped item (7) of food is fed to the cutting device by means of the feed device, and the cutting device cuts the string shaped item (7) into pieces, strips or blocks. The string shaped item (7) is fixed by a vaccum gripper(1) which is fed along with the item (7) during feed movement. The method involves producing a negative pressure in an interior of a contact element (29) of a vacuum gripper, where the pressure acts on a fixing region (42,43) of a surface of the string shaped item (7) in an internal suction region(36,37) of the contact element(29). The item(7) is cut by at least two annular cutting edges(33,35) which encloses the suction region(36,37) of the contact element (29) for improving seal performance of the suction region(36,37).

Owner:尤维‧赖芬豪瑟

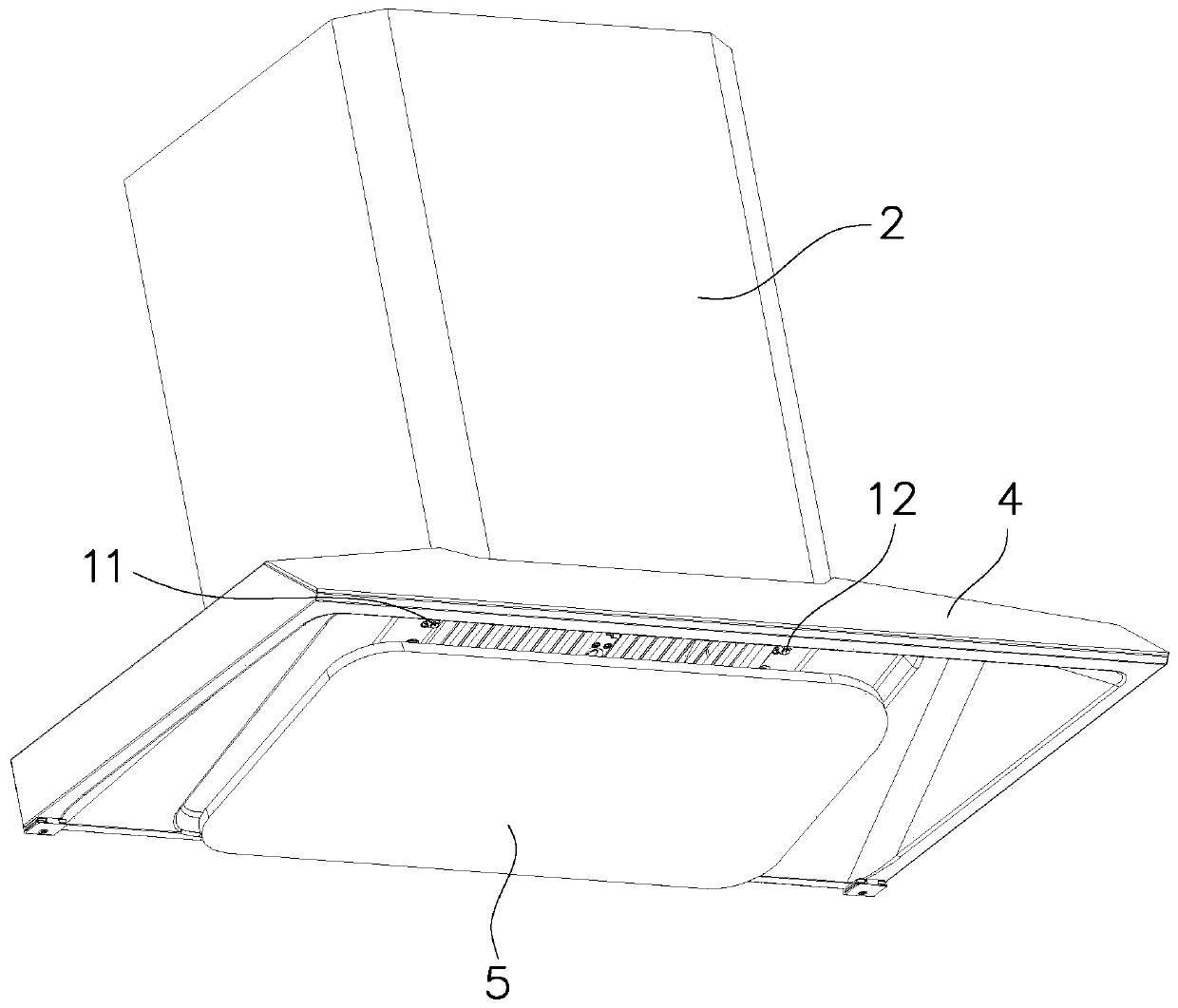

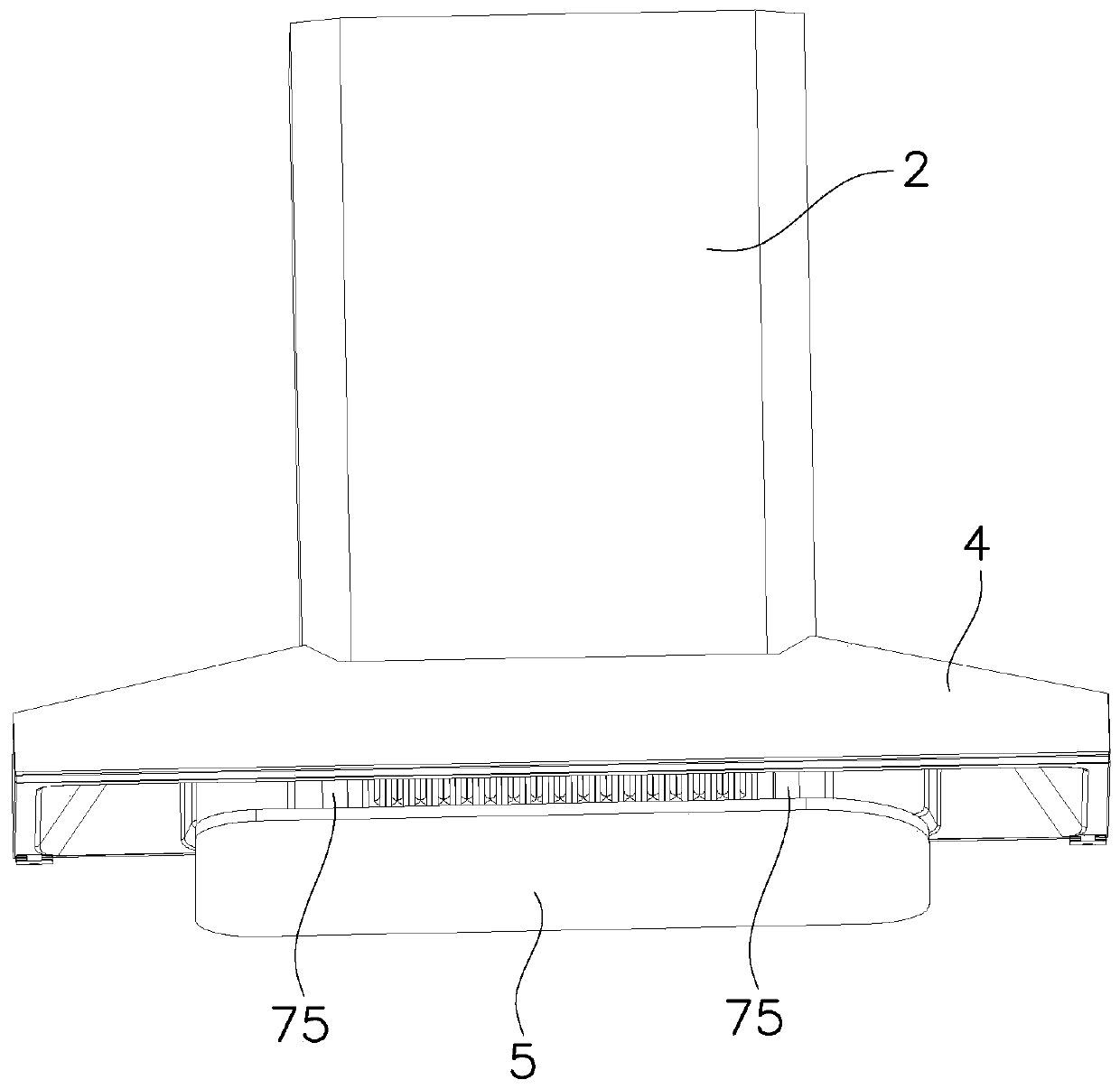

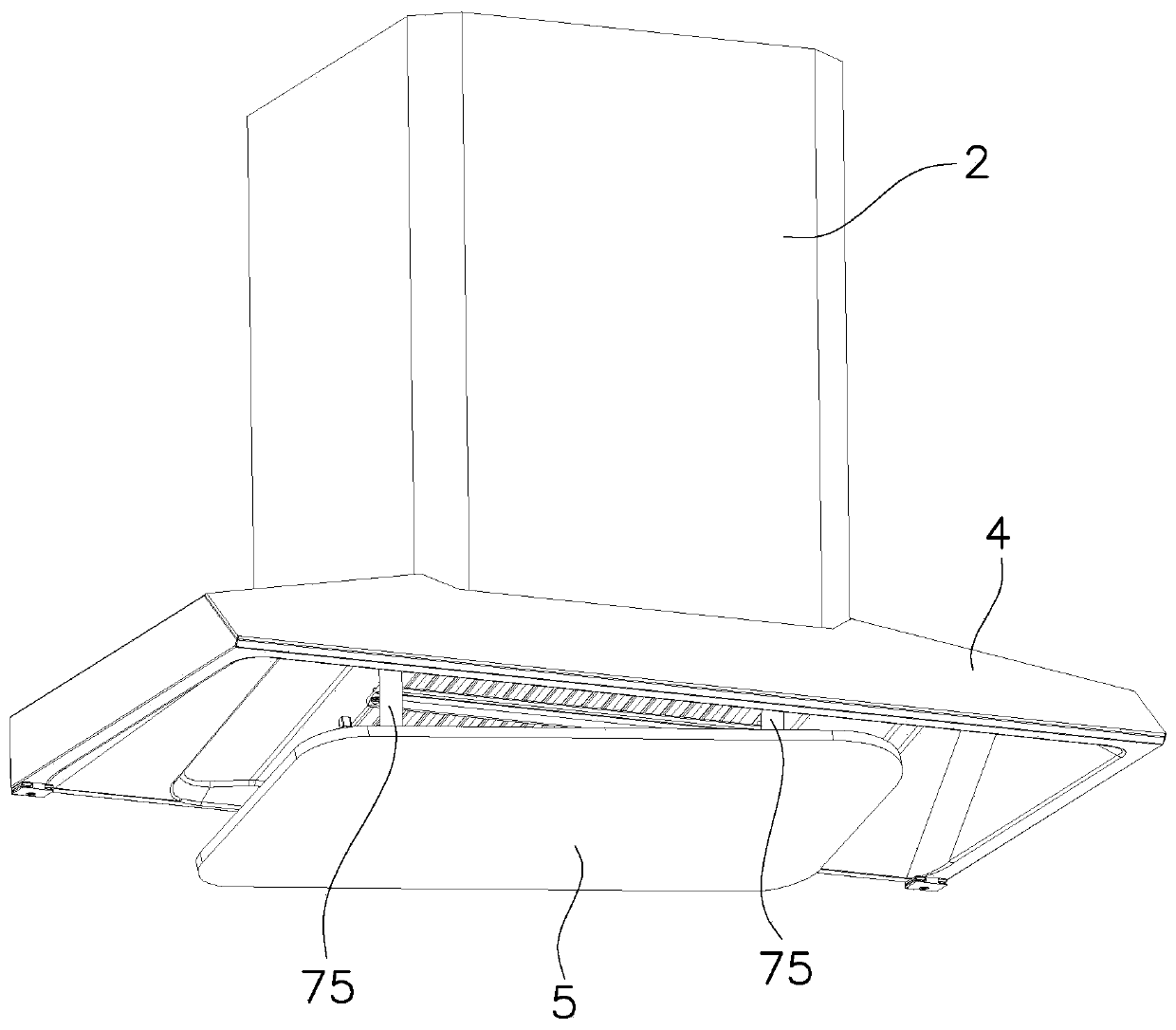

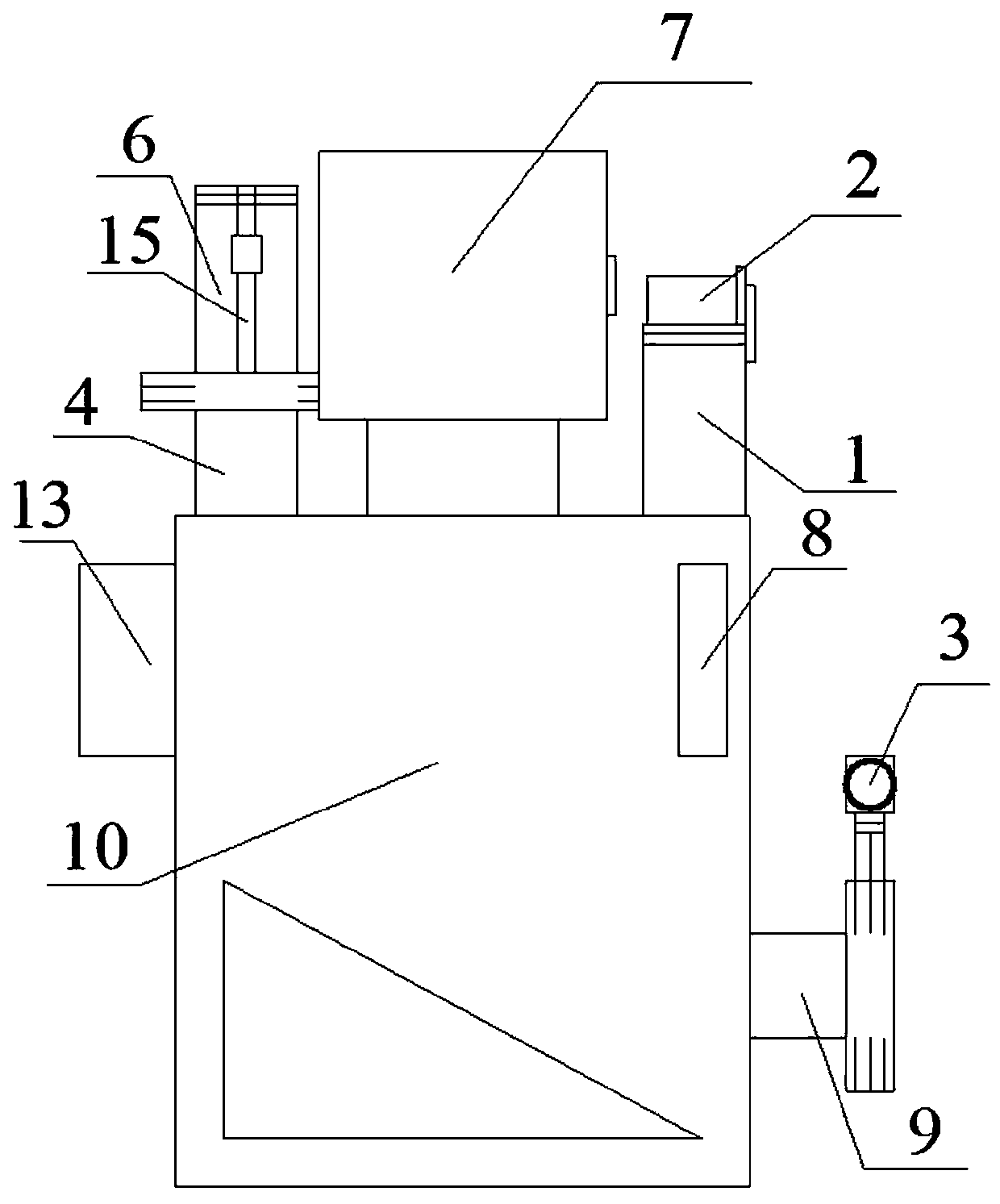

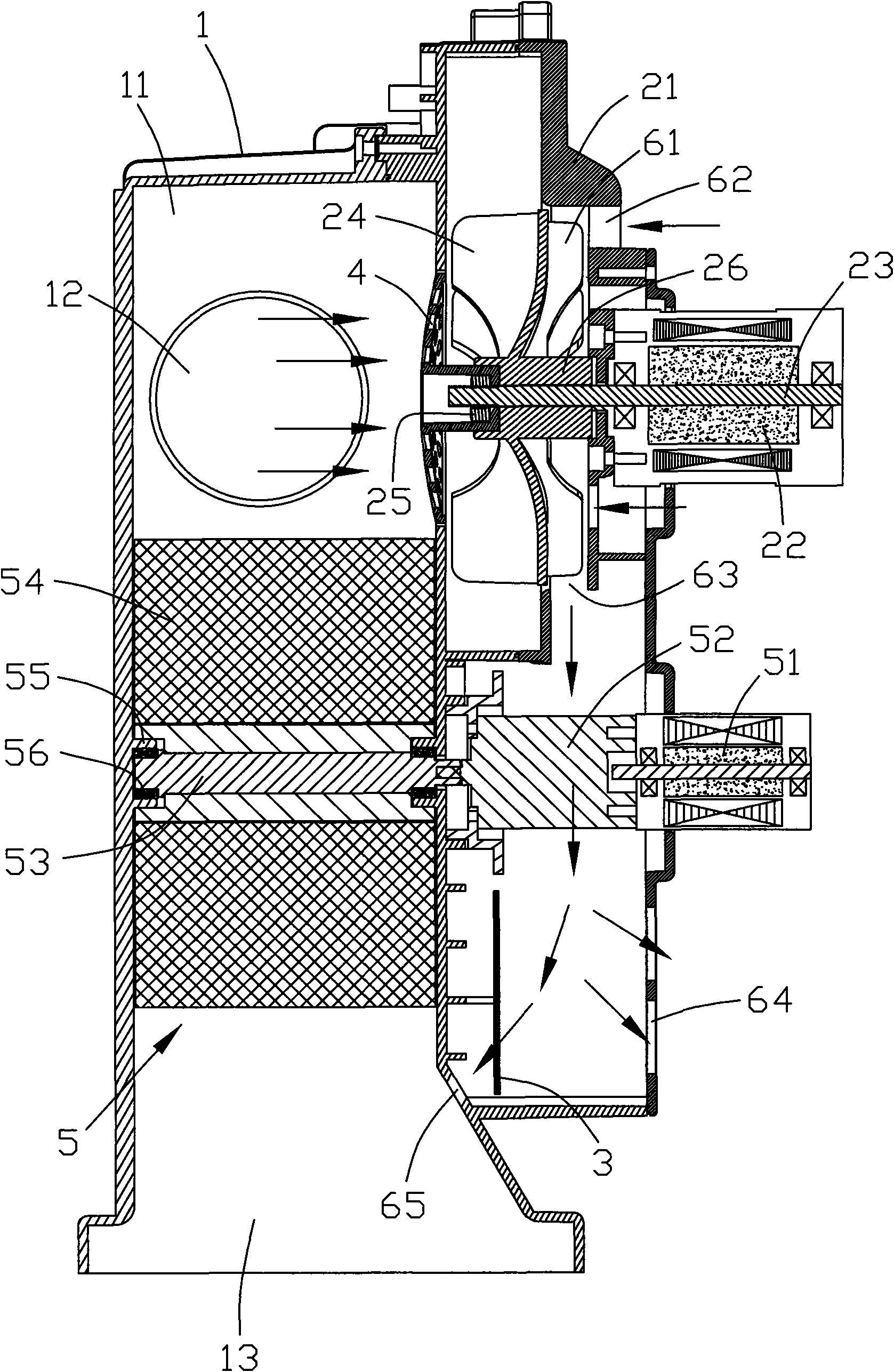

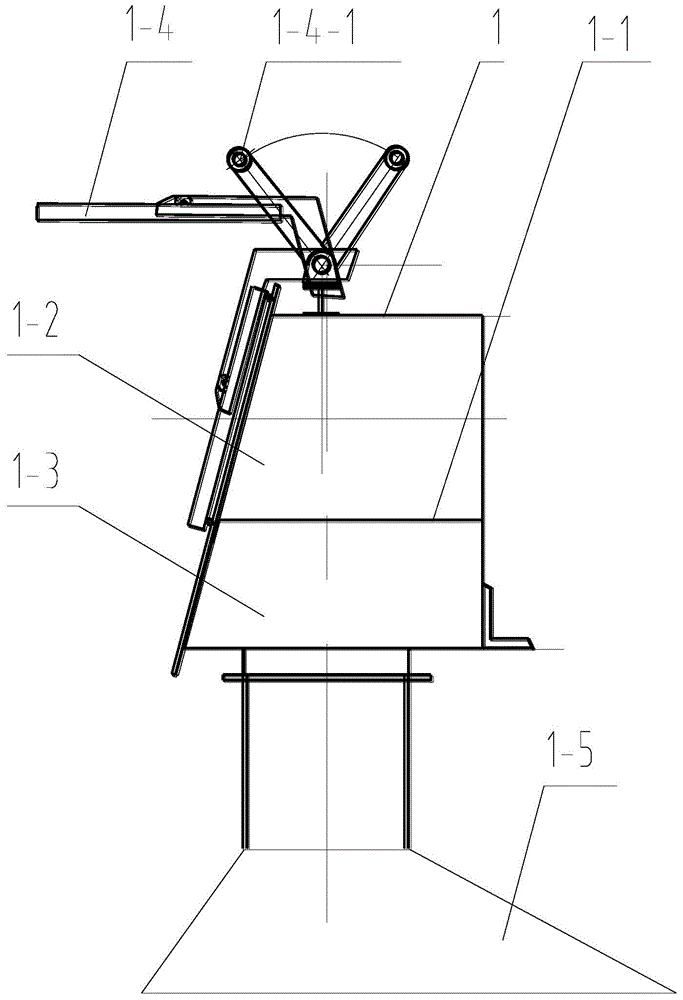

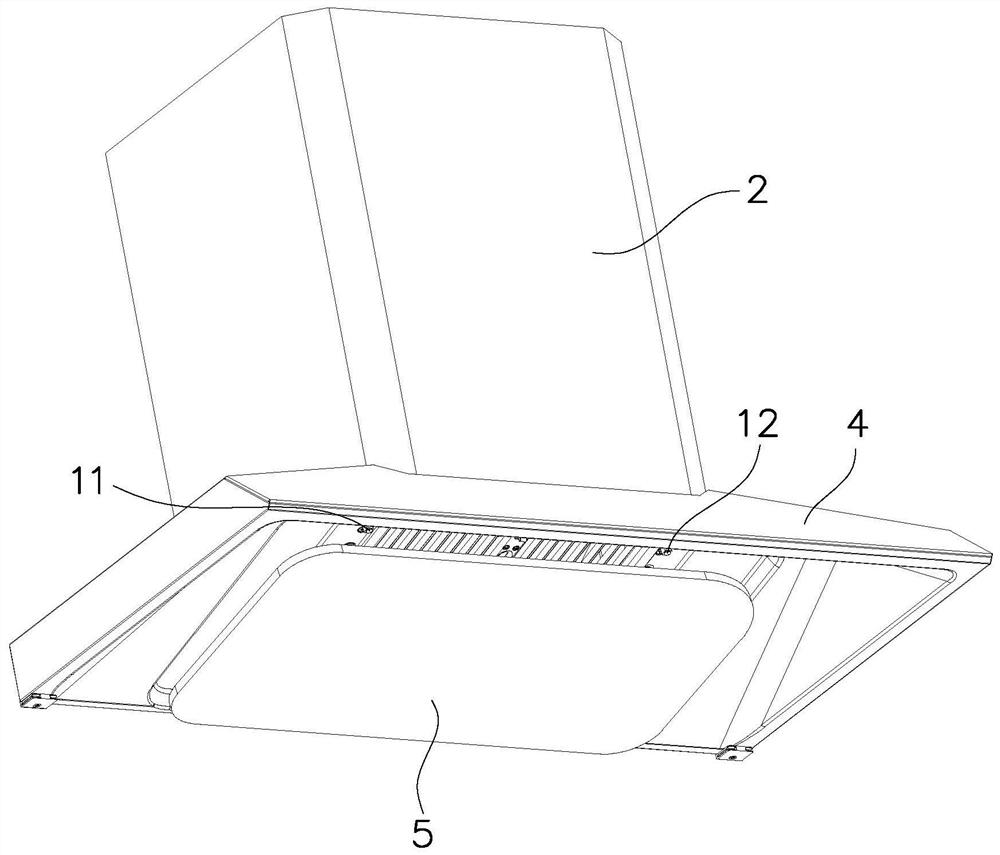

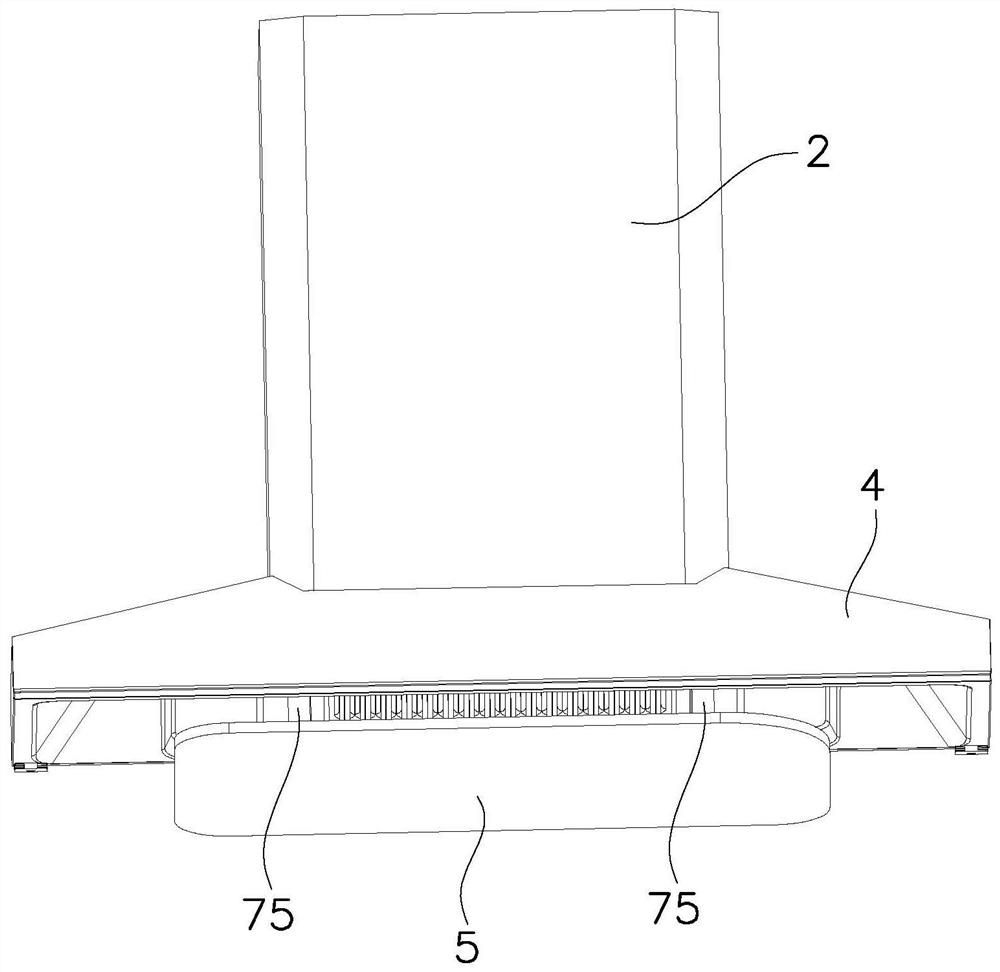

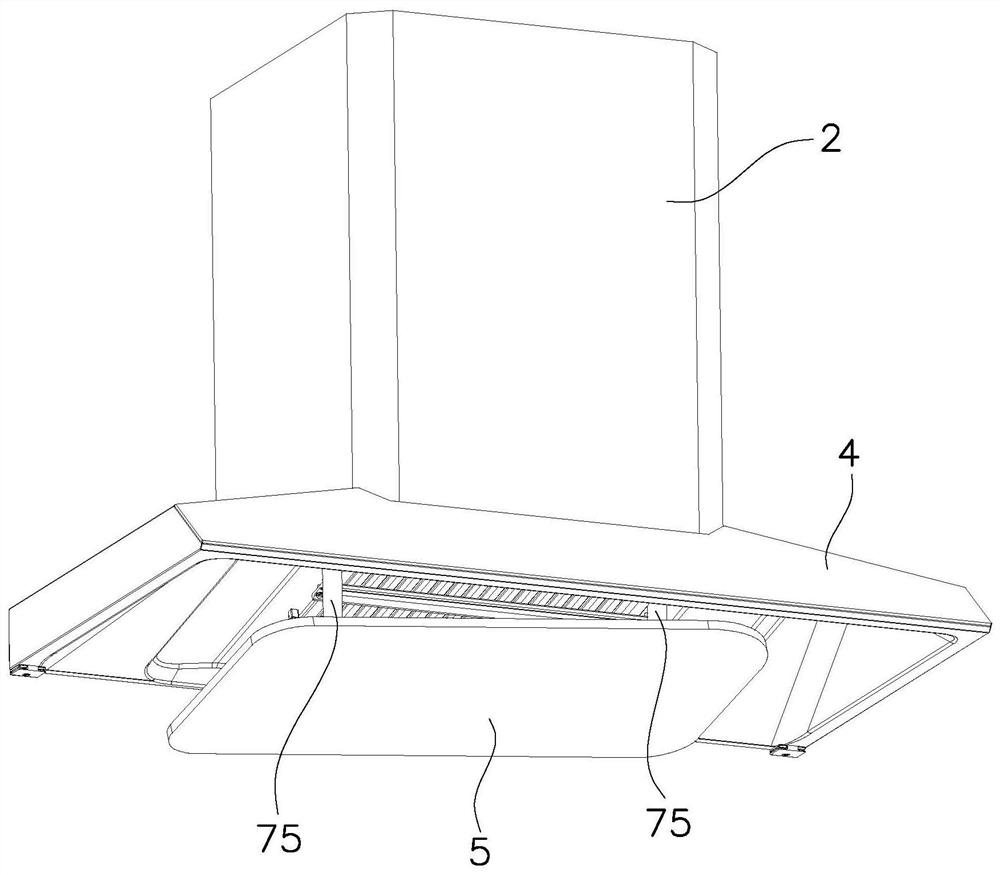

Range hood with movable smoke guide plate and control method thereof

ActiveCN111102621AAchieve liftingReduce negative pressure lossDomestic stoves or rangesLighting and heating apparatusStructural engineeringSmoke hood

The invention discloses a range hood with a movable smoke guide plate and a control method thereof. An installation cavity is formed between a fan frame and a decoration outer cover, a smoke collection cover is installed below the decoration outer cover, a smoke guide plate is installed below an air inlet of the smoke collection cover, a volute positive pressure drainage pipe and a lifting mechanism are installed in the installation cavity, the air inlet end of the volute positive pressure drainage pipe communicates with the interior of a volute of the fan, the air outlet end of the volute positive pressure drainage pipe is connected with a driving mechanism, so that the airflow flowing out from the air outlet end forms a driving source of the driving mechanism, and the smoke guide plate can move relative to the smoke collection cover under the driving of the lifting mechanism. The range hood has the advantages that the airflow led out from the interior of the volute through the volutepositive pressure drainage pipe can be used as a driving source to drive the lifting mechanism, so that the smoke guide plate can move relative to the smoke collection cover, and the motion posture of the smoke guide plate is intelligently adjusted; the moving parts are few, the structure is simple, the cost is low, the disassembly and assembly are easy, the reutilization of airflow inside the volute is realized, and the negative pressure loss of the range hood is reduced.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

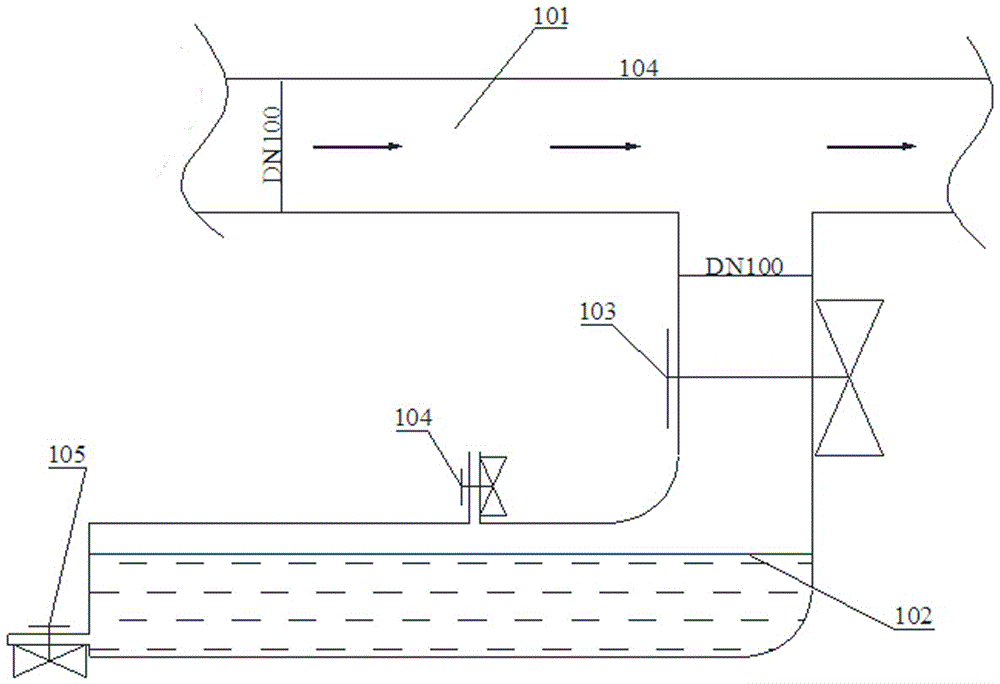

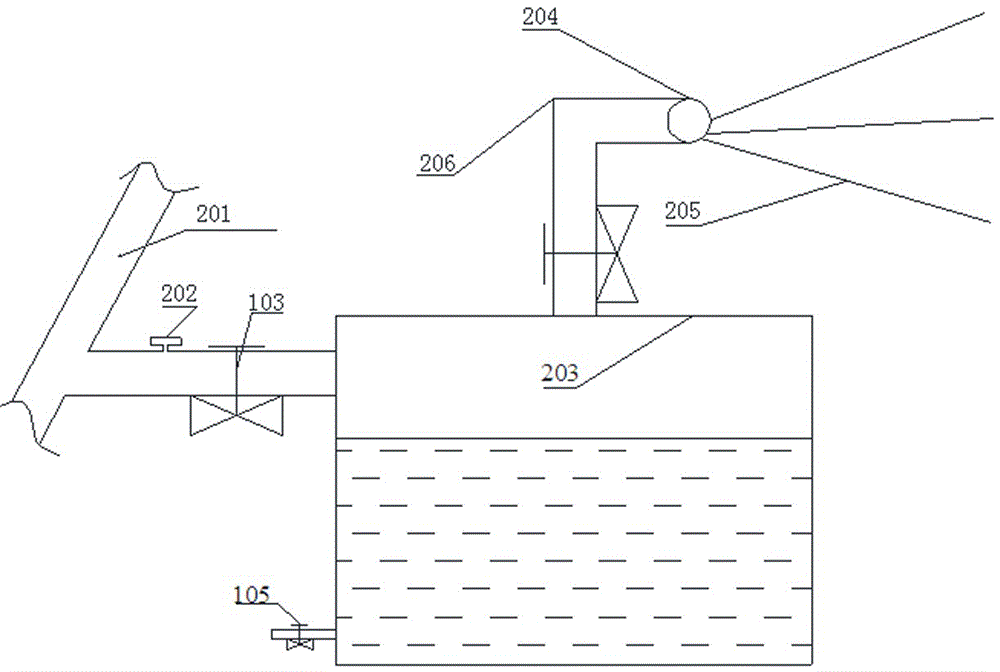

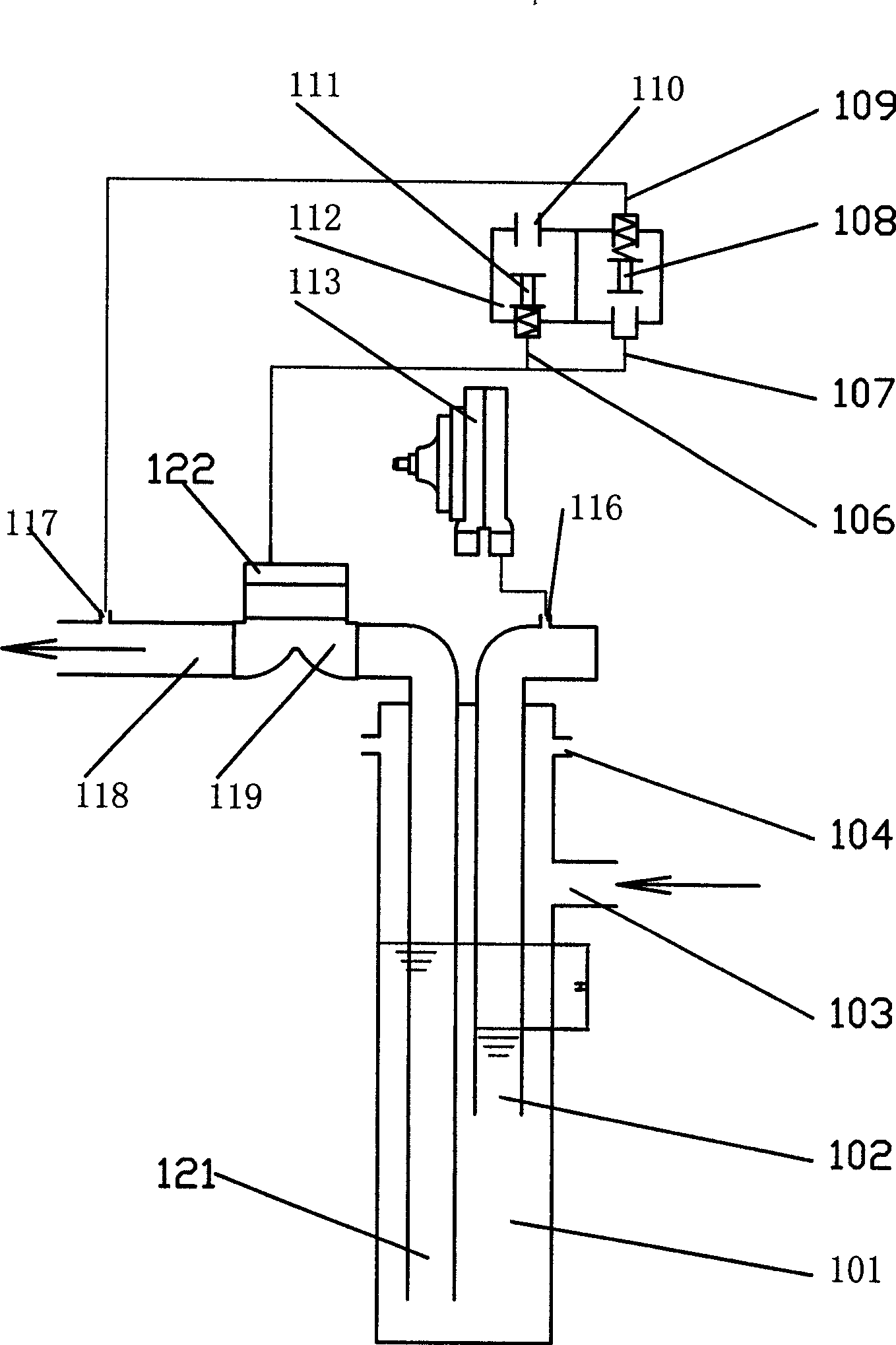

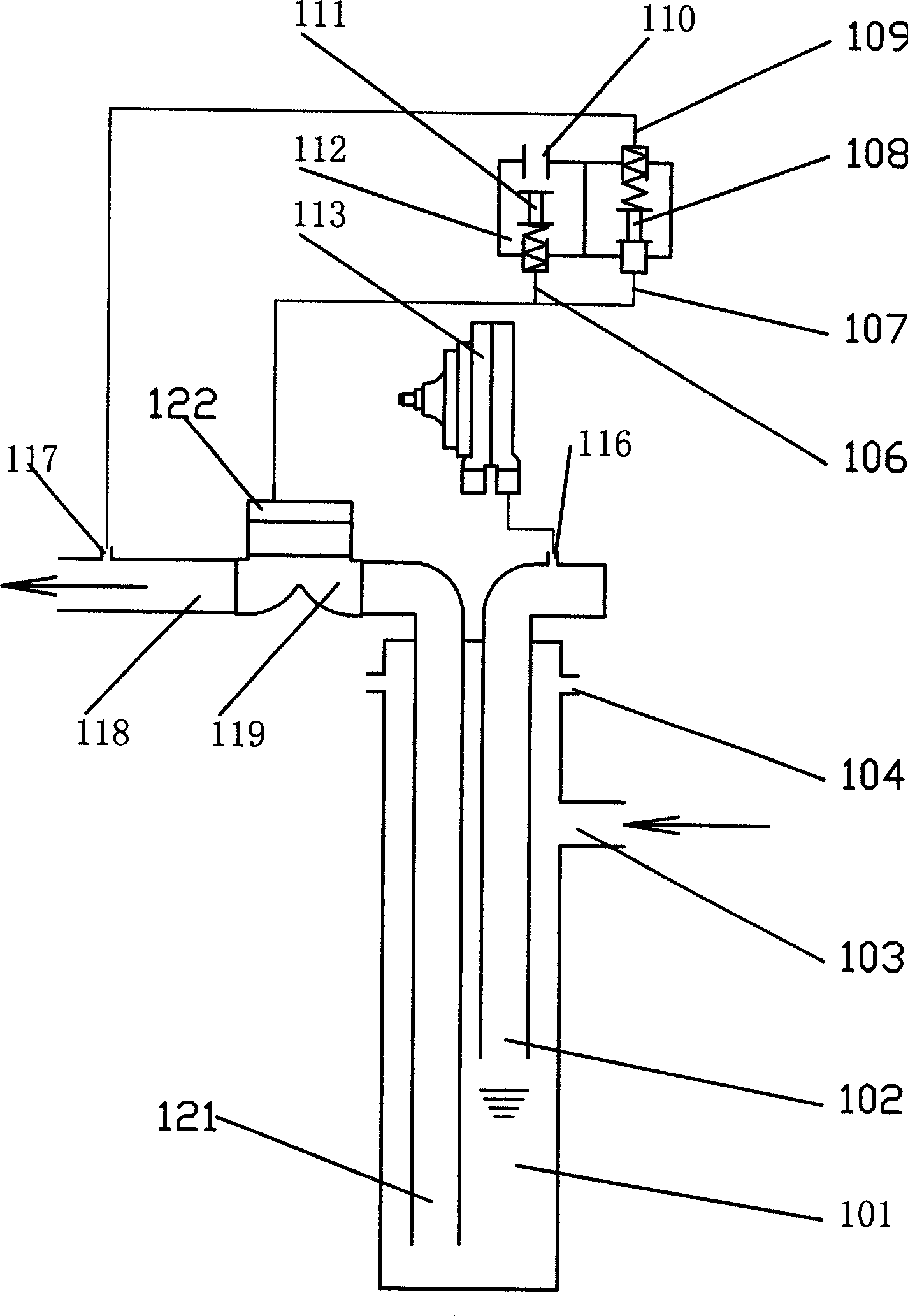

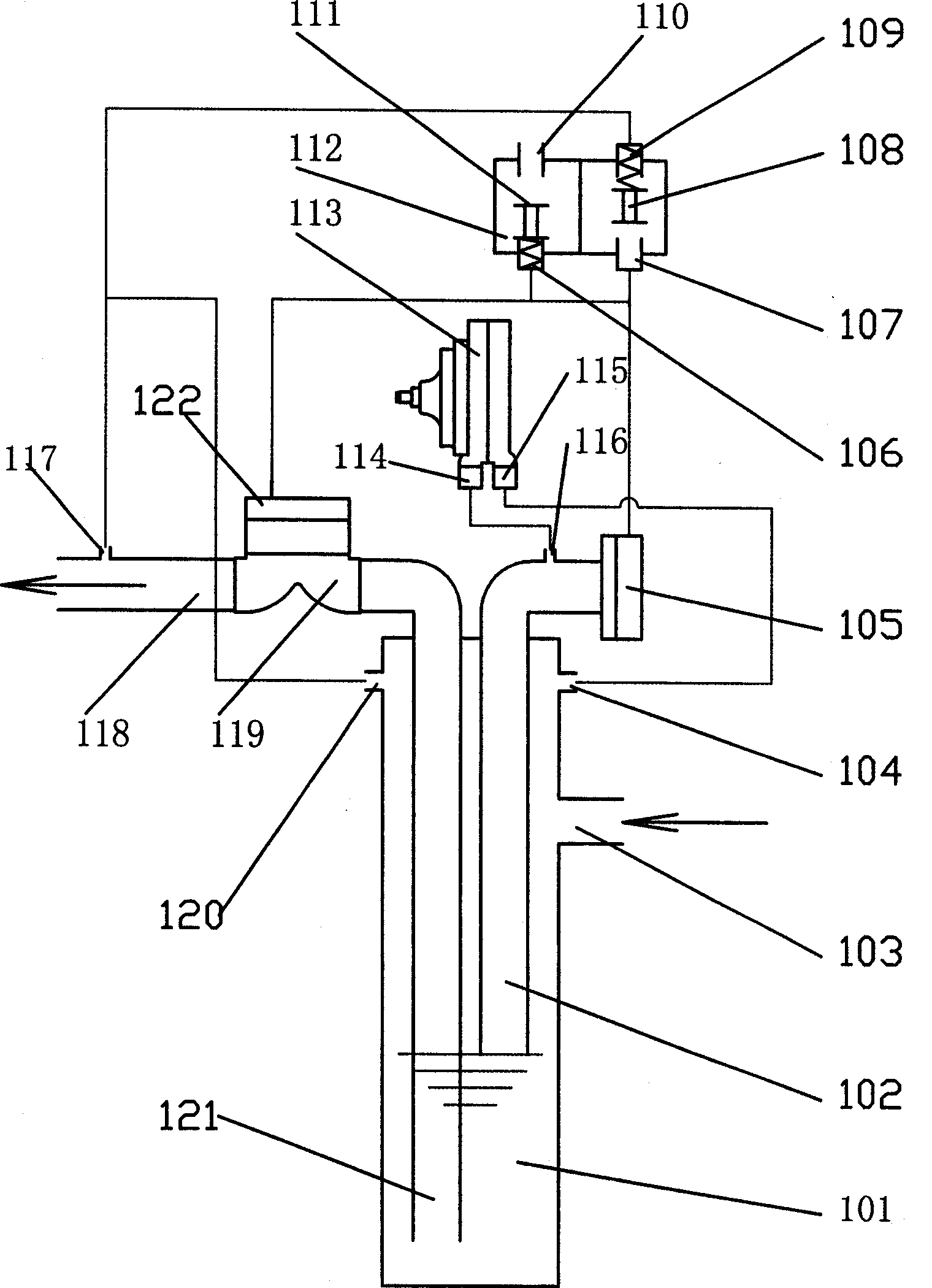

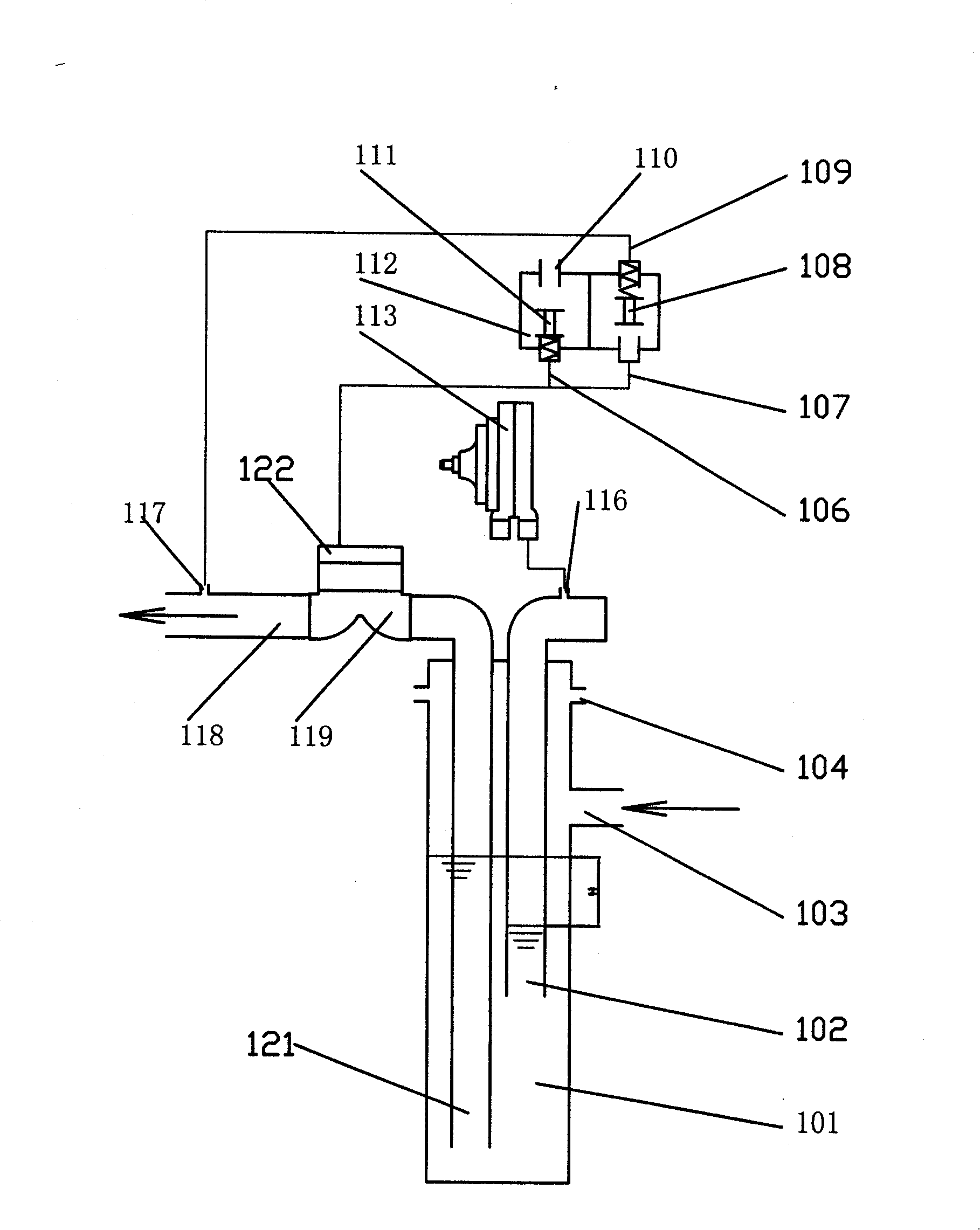

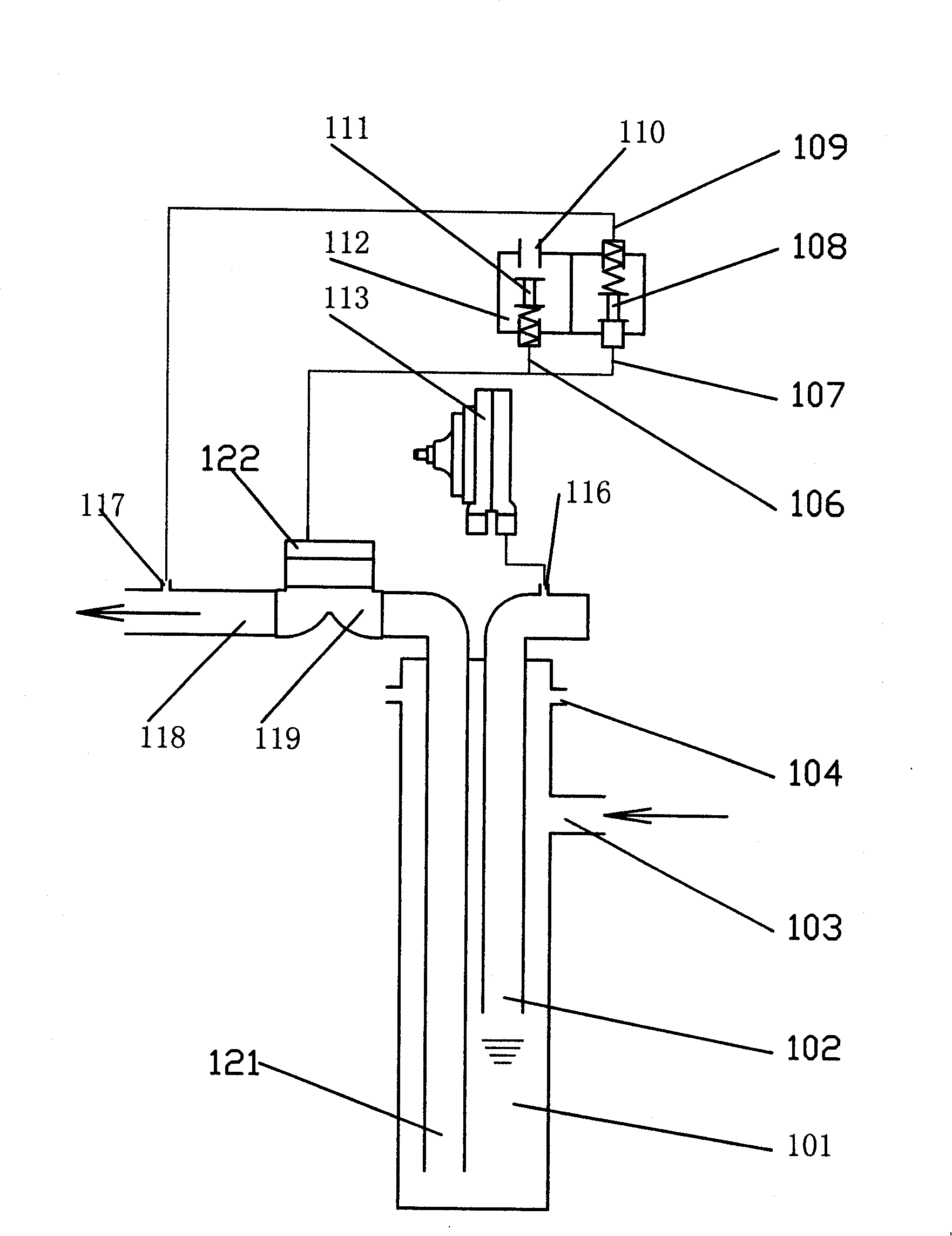

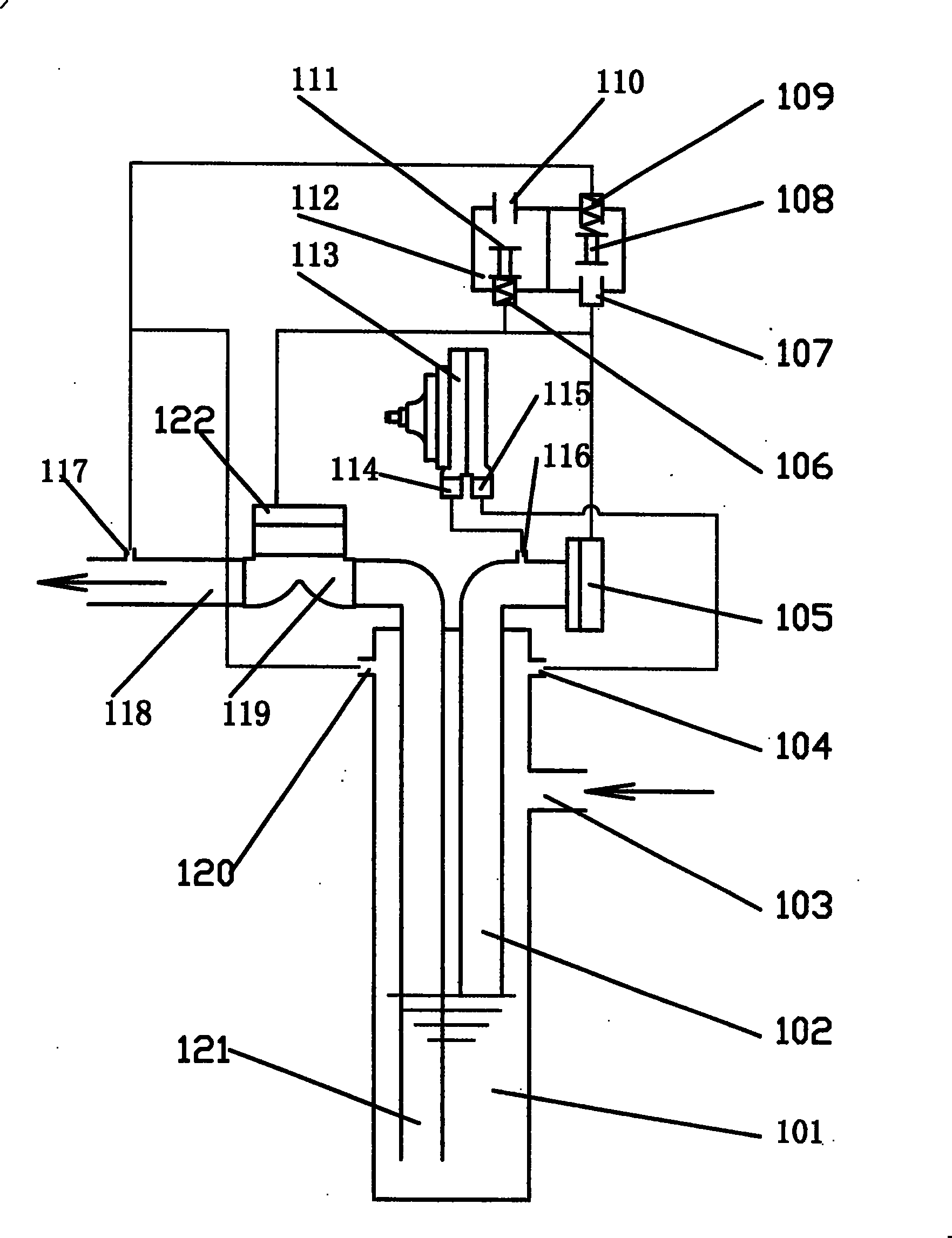

Intermediate storage tank and sewage source separation system based on negative pressure

ActiveCN101363241AIncrease flow rateSave powerSewerage structuresClimate change adaptationInternal pressureControl signal

The invention relates to an intermediate storage tank for collecting domestic sewage and also relates to a domestic sewage source separation system under negative pressure adopting the intermediate storage tank. The intermediate storage tank comprises a tank body, an induction valve, a control valve, a storage tank sewage discharge negative pressure valve and a microprocessor, wherein, the tank body is provided with an induction tube and a storage tank sewage discharge pipe, the upper middle part of the tank body is provided with a sewage inlet and the upper part of the tank body is provided with one or a plurality of air inlets, the lower end ports of the induction tube and the storage tank sewage discharge pipe are positioned inside the tank body, the upper part of the inner cavity of the induction tube is communicated with the induction valve by an internal pressure connecting mouth, an induction signal output route of the induction valve is connected with a signal input terminal of the microprocessor, a control signal output line of the microprocessor is connected with a control route of the control valve, a negative pressure control pipeline of the control valve is connected with a negative pressure control cavity of the storage tank sewage discharge negative pressure valve, and the storage tank sewage discharge pipe is connected with a negative pressure sewage discharge pipeline by the storage tank sewage discharge valve. The domestic sewage source separation system comprises a plurality of the intermediate storage tanks and one or a plurality of sewage collection tanks, and is provided with a uniform negative pressure source. The domestic sewage source separation system is beneficial to reducing power consumption and realizing the source separation of the domestic sewage.

Owner:ENVIROSYST BEIJING ENVIRONMENTAL ENG & TECH CO LTD

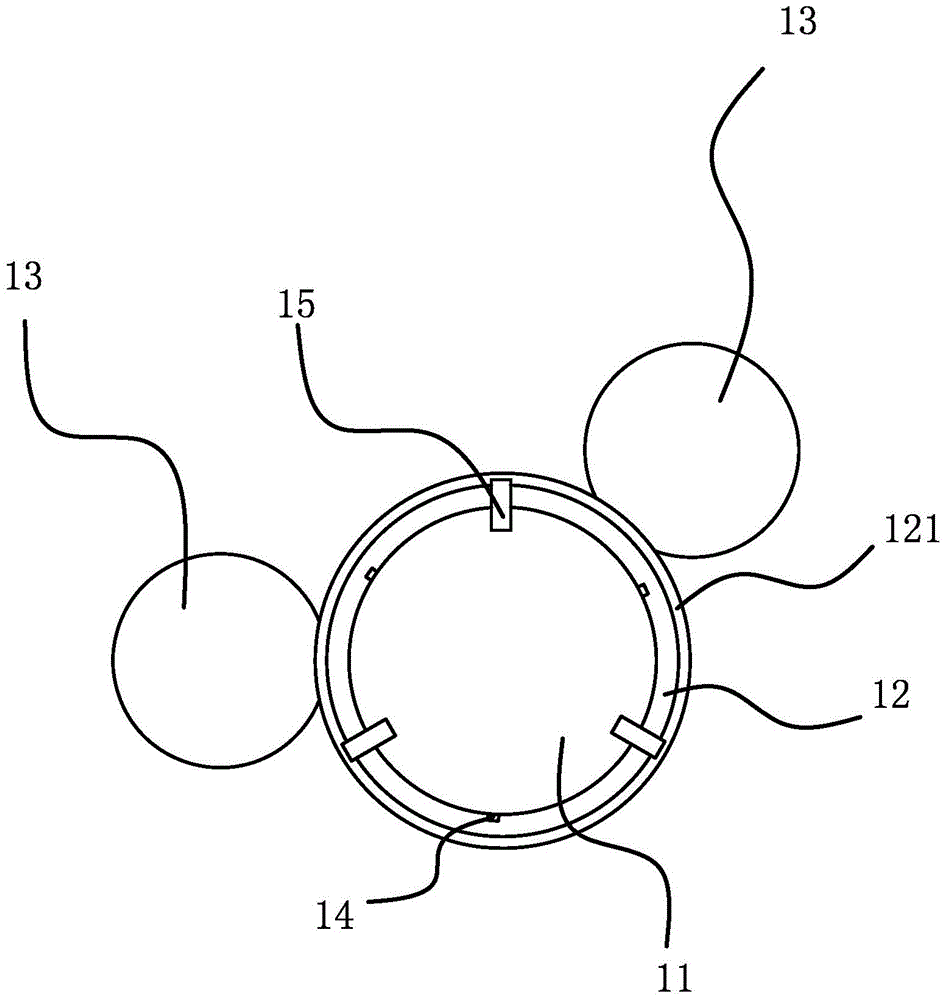

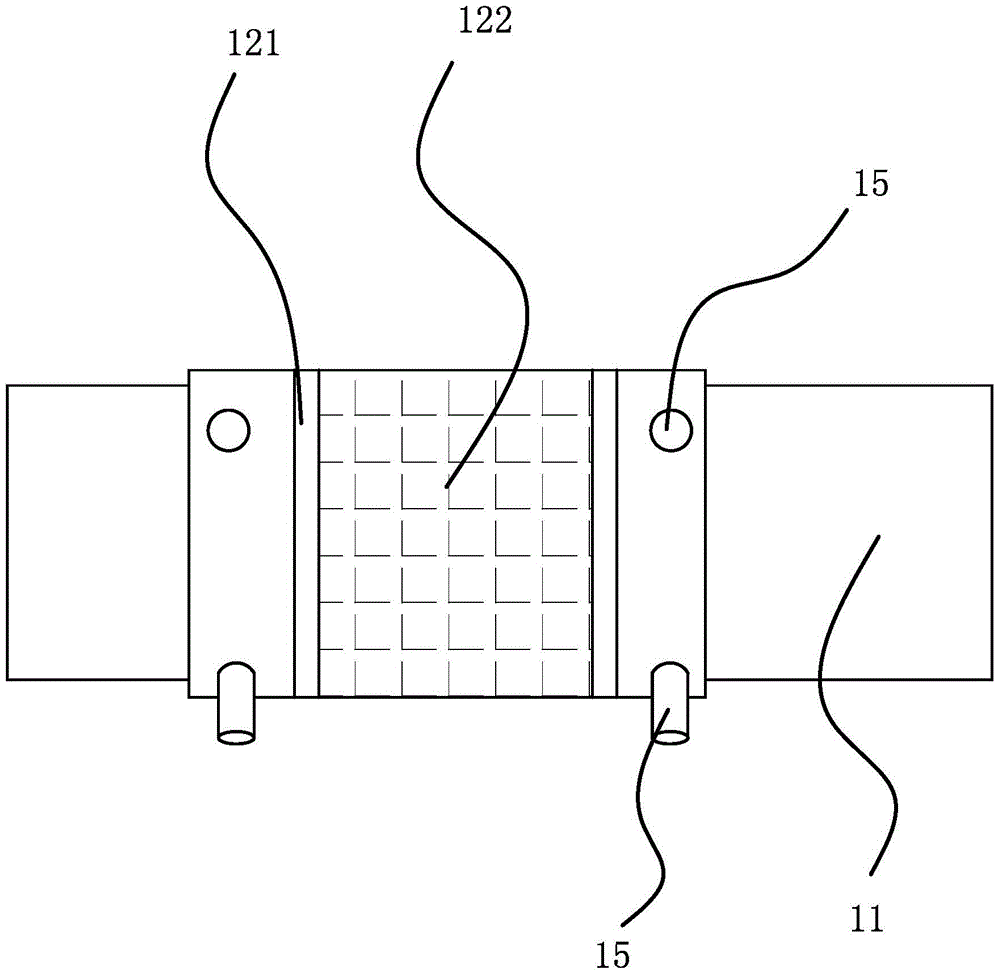

Negative pressure type tight siro spinning machine

InactiveCN104195683ALow costReduce replacement costsDrafting machinesProduction linePulp and paper industry

The invention provides a negative pressure type tight siro spinning machine and belongs to the technical field of spinning. The negative pressure type tight siro spinning machine solves the problems that hair and end-broken strips in a waste cotton collecting box cannot be removed conveniently by an existing negative pressure type tight siro spinning machine, the machine needs to be shut down completely in the removing time, draught fans are stopped, the whole production line cannot work continuously, and consequently the yield is reduced. The negative pressure type tight siro spinning machine comprises a rack, a front roller device, a middle roller device, a rear roller device, a guide wire, a special-shaped pipe device and an air sucking device are arranged on the rack, the air sucking device comprises an air sucking branch pipe communicated with a negative pressure gathering pipe of the special-shaped pipe device, a cotton sucking pipe with a port facing the surface of the front roller assembly, a negative pressure air collecting pipeline connected with the air sucking branch pipe, a cotton sucking and air collecting pipeline communicated with the cotton sucking pipe and a draught fan box. A negative pressure draught fan, a centrifugal draught fan and a cotton removing air pump do not interfere with one another, an operator can remove the hair stored in the waste cotton collecting box at any time, and normal work of the spinning machine is not affected.

Owner:HAINING FULIDA TEXTILE

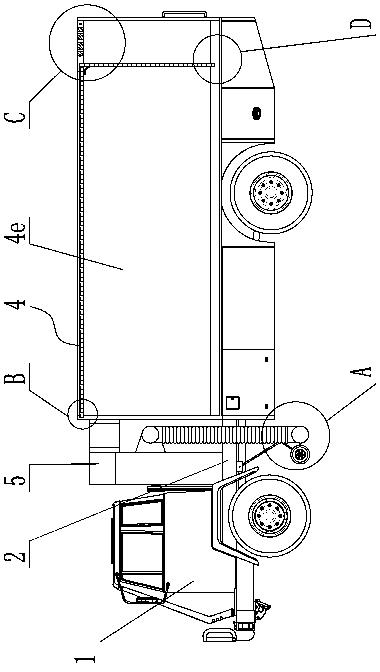

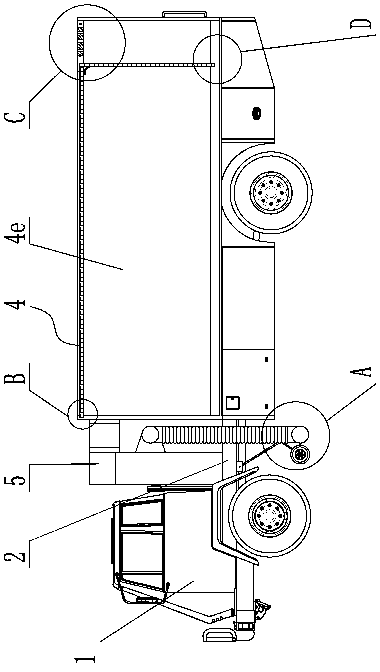

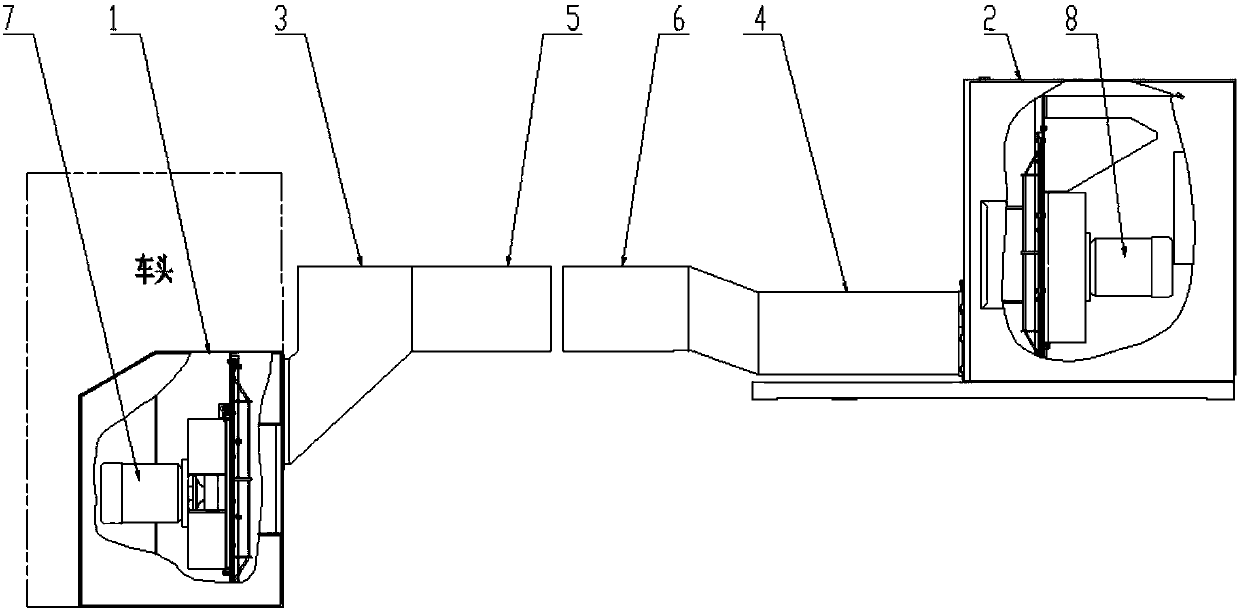

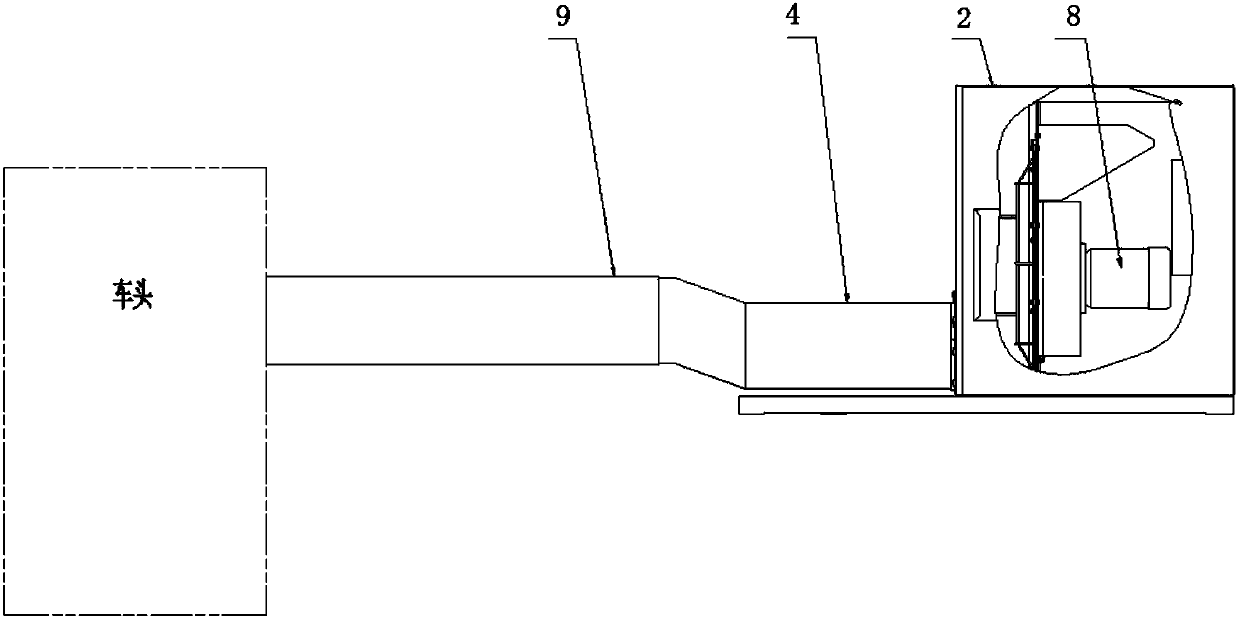

Dust-collection sanitation vehicle

ActiveCN105780699AReduce input powerReduce energy consumptionGas treatmentDispersed particle filtrationVehicle frameEngine power

The invention provides a dust-collection sanitation vehicle. The dust-collection sanitation vehicle comprises a cab, a vehicle frame, an engine power output shaft and a compartment. A draught fan is installed on the vehicle frame. A driving belt wheel is installed on the engine power output shaft. A driven belt wheel is installed on a draught fan spindle. The driving belt wheel is in transmission connection with the driven belt wheel through a belt. The lower portion of the vehicle frame is connected with a main dust collection pipe. The main dust collection pipe is provided with a dust collection port. The main dust collection pipe is connected with an air suction port of the draught fan through a telescopic hose. The compartment comprises a base plate, side plates, a front plate and a tail door. A first dust filtering plate assembly and a second dust filtering plate assembly are detachably connected to the interior of the compartment. The first dust filtering plate assembly is vertically arranged on the tail of the compartment and spaced from the tail door by a certain distance. The second dust filtering plate assembly is horizontally arranged at the top of the compartment. A dust collection cavity used for collecting dust is defined by the base plate, the side plates, the front plate, the first dust filtering plate assembly and the second dust filtering plate assembly. An air inlet communicating with the dust collection cavity is formed in the compartment. An air outlet of the draught fan is connected with the air inlet in the compartment.

Owner:邯郸极驰汽车股份有限公司

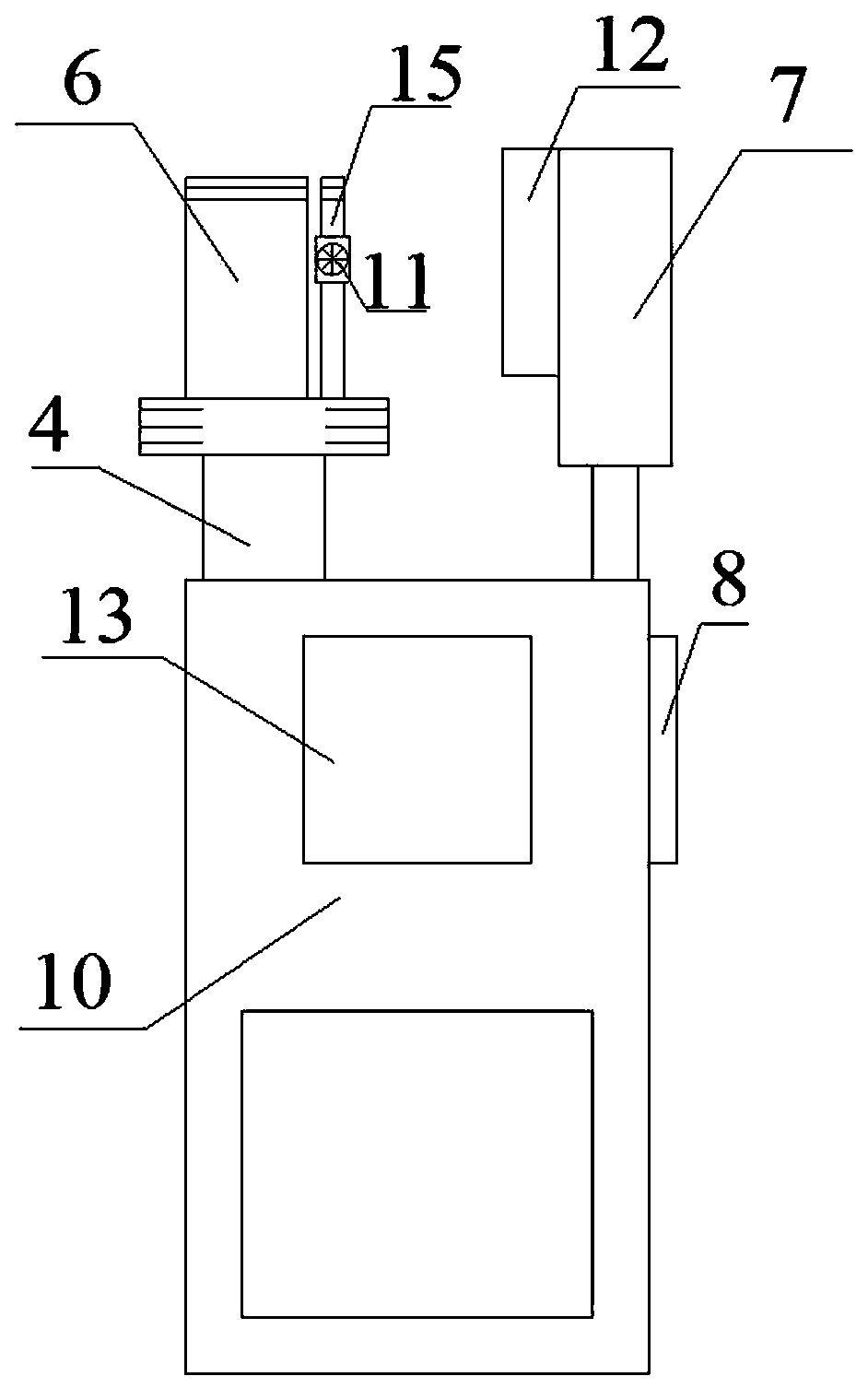

Novel concentration-pressure sensing type flow control device and use method thereof

PendingCN111396135AReduce negative pressure lossReduce gas gushingMining devicesMeasurement devicesAutomatic controlDrill hole

The invention discloses a novel concentration-pressure sensing type flow control device. The device comprises a box body, wherein the box body comprises an air and water inlet, an extraction opening and a water and slag discharge opening, the extraction opening comprises a main extraction pipeline and a low-concentration extraction pipeline, one side of the extraction opening is fixedly connectedwith a three-way pneumatic valve, the three-way pneumatic valve communicates with the main extraction pipeline and the low-concentration extraction pipeline, the top surface of the box body is fixedlyconnected with a pressure sensor and a gas concentration sensor, and gas is controlled to flow to the main extraction pipeline or the low-concentration extraction pipeline through opening and closingof the three-way pneumatic valve. According to the device and the method, a gas extraction negative pressure supply channel, namely a channel for drilling gas from the box body to the temporary extraction system pipeline, is automatically adjusted by detecting the concentration and pressure of the drilling gas, automatic flow control can be achieved, the loss of the negative pressure of an underground extraction pipeline is effectively reduced, and the utilization rate of underground gas is increased.

Owner:JIAOZUO COAL IND GRP CO LTD

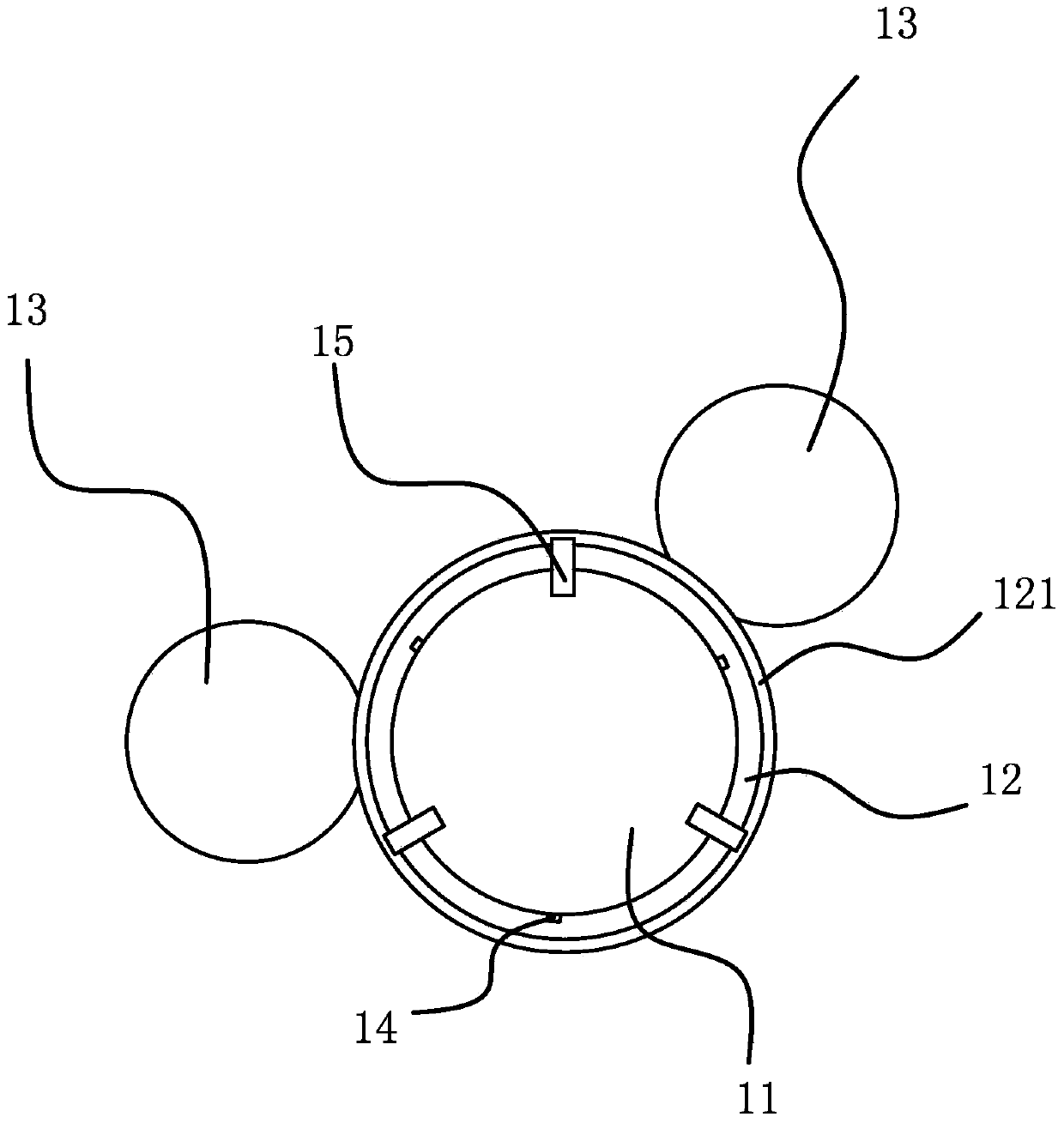

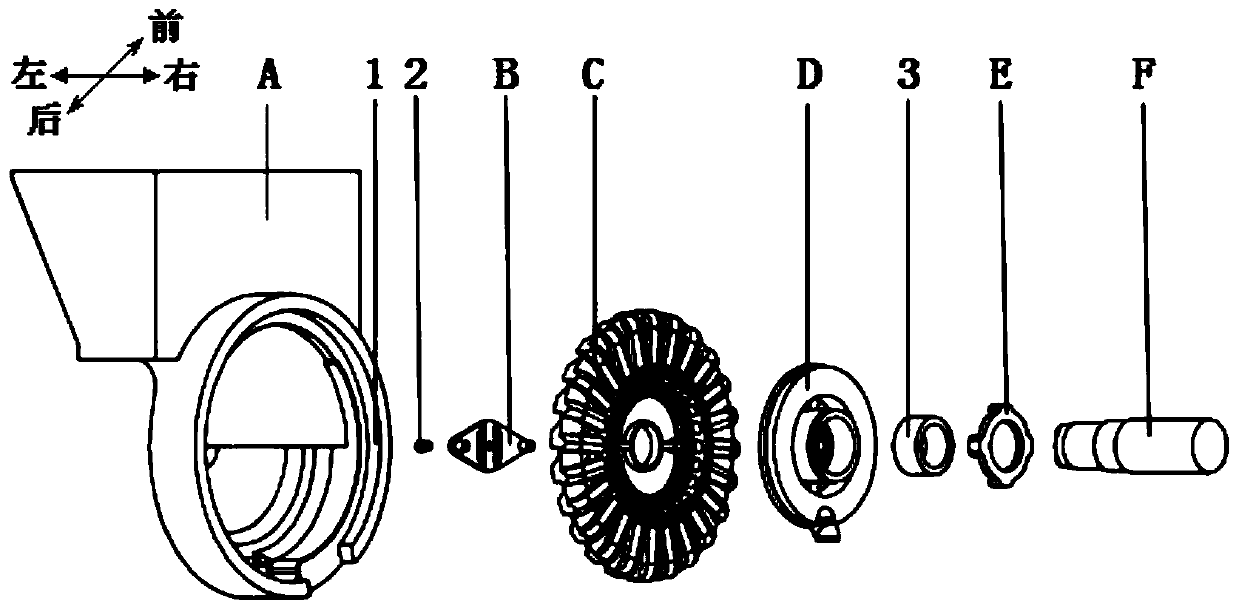

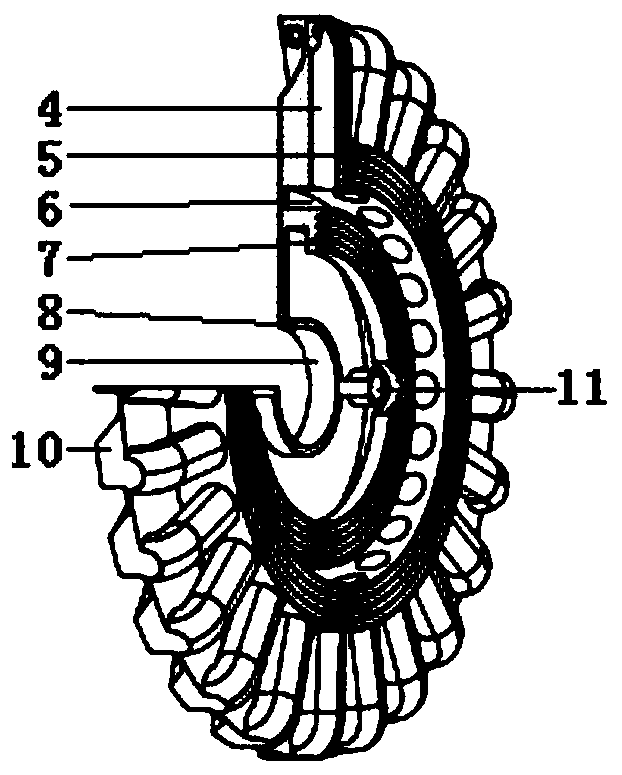

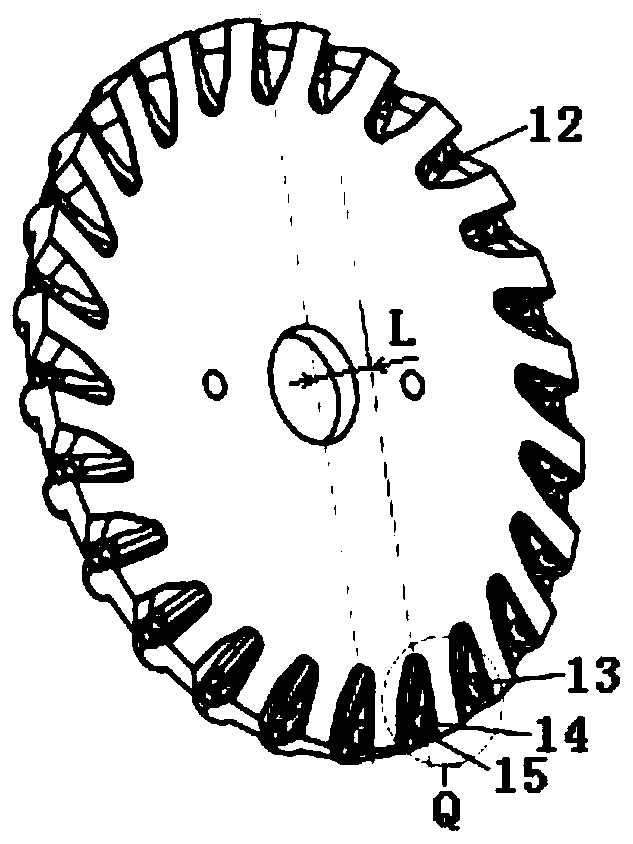

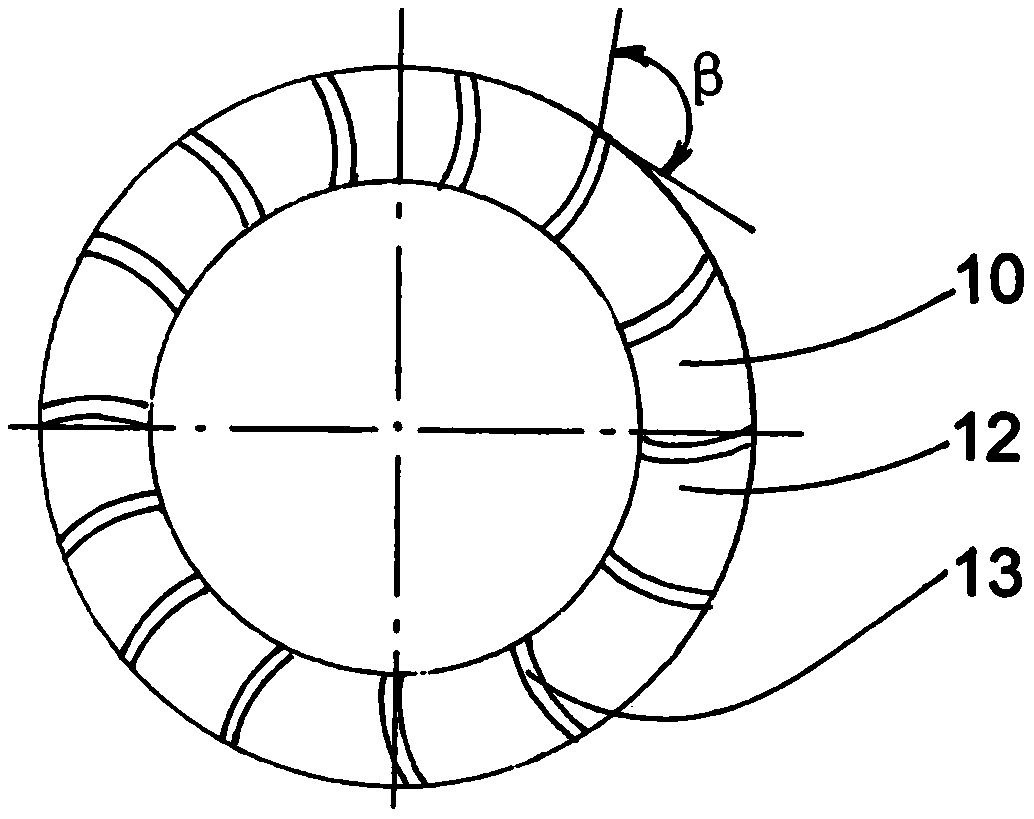

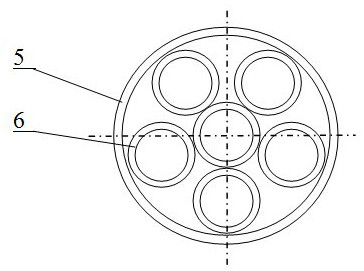

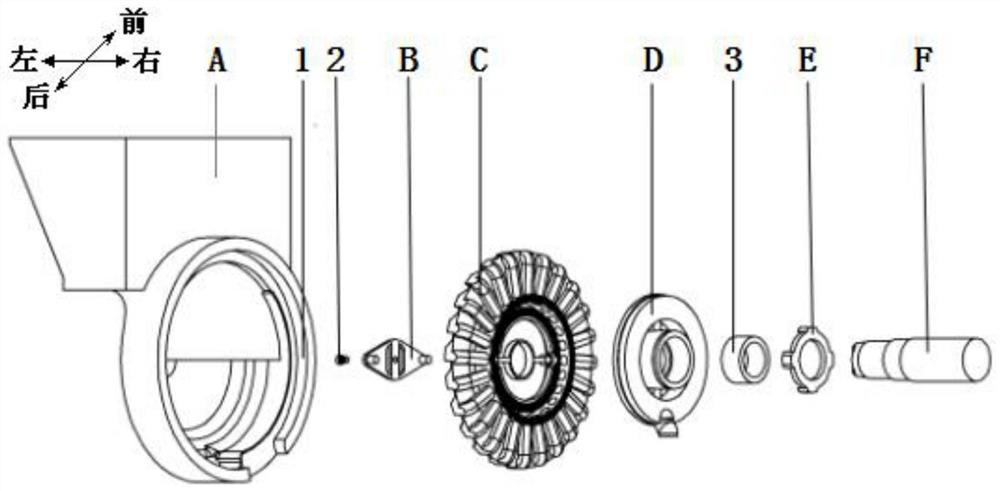

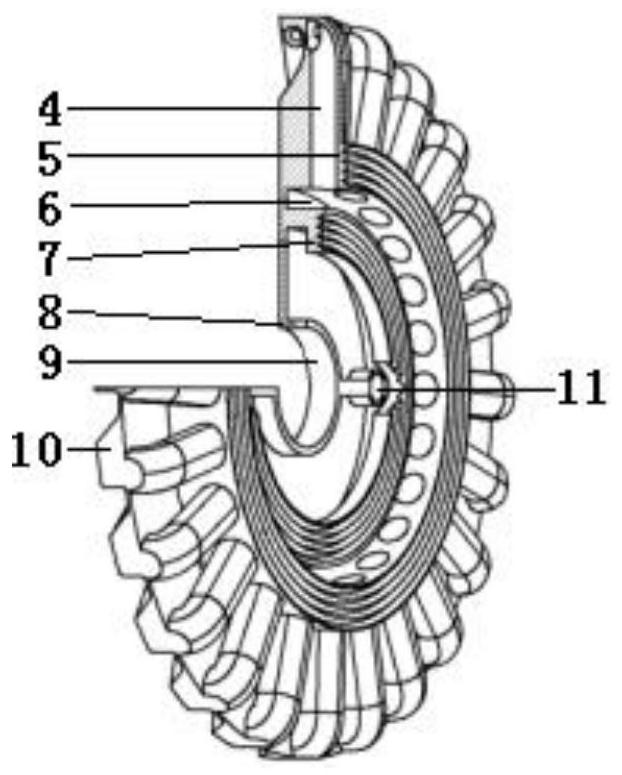

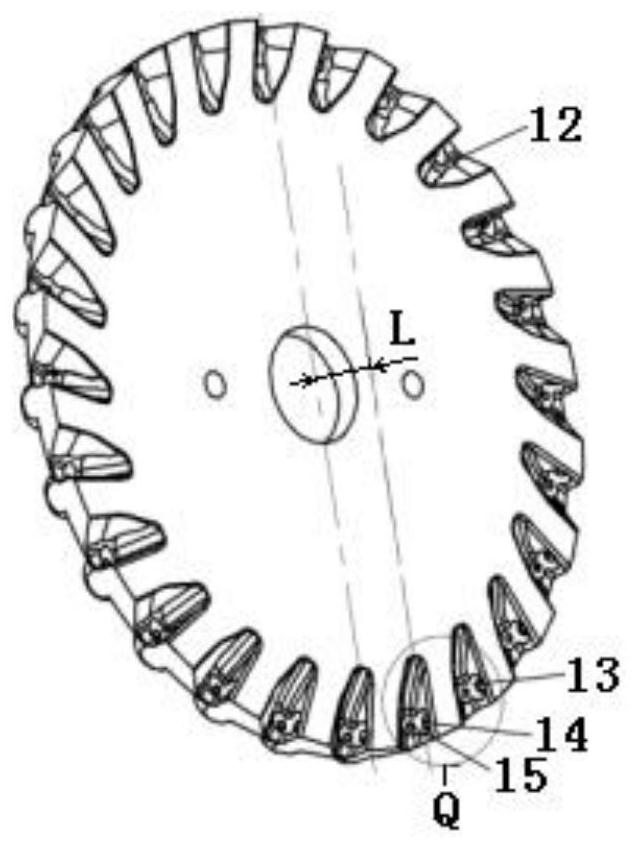

Double-hole air-suction type soybean and corn universal energy-saving seed metering device

InactiveCN110073775AIncrease general seeding effectImprove adsorption capacitySingle grain seedersInterference fitEngineering

The invention provides a double-hole air-suction type soybean and corn universal energy-saving seed metering device, which belongs to the technical field of agricultural machinery. In the invention, the edge of a disc body of the seed metering device is provided with a double-suction-hole seed taking groove, and a groove is arranged in the seed taking groove for soybean taking; the double suctionholes are connected with an air suction passage, the air suction passage is connected with the double suction holes and a negative pressure chamber, and the negative pressure chamber is formed by thecombination of the disc body and an air cover; the air cover has an air extraction hole and an air blocking block, and an isosceles cone ring is arranged on the air cover and the disc body; the air cover is matched with the bearing, the air cover is tightly buckled to the bearing by a ring buckle, the bearing and a second shaft surface of a shaft are in interference fit, and the disc body is tightly buckled to a rotating shaft by a buckle to ensure clearance fit between the disc body and the isosceles cone ring of the air cover. By adoption of the seed metering device of the invention, the universal seed metering of soybean and corn is realized, and known from aerodynamics, the waist faces of the isosceles cone rings are in clearance fit to form a continuous curved path, which can generatea throttling effect on the airflow, thereby reducing the air pressure loss of the air suction type seed metering device.

Owner:JILIN UNIV

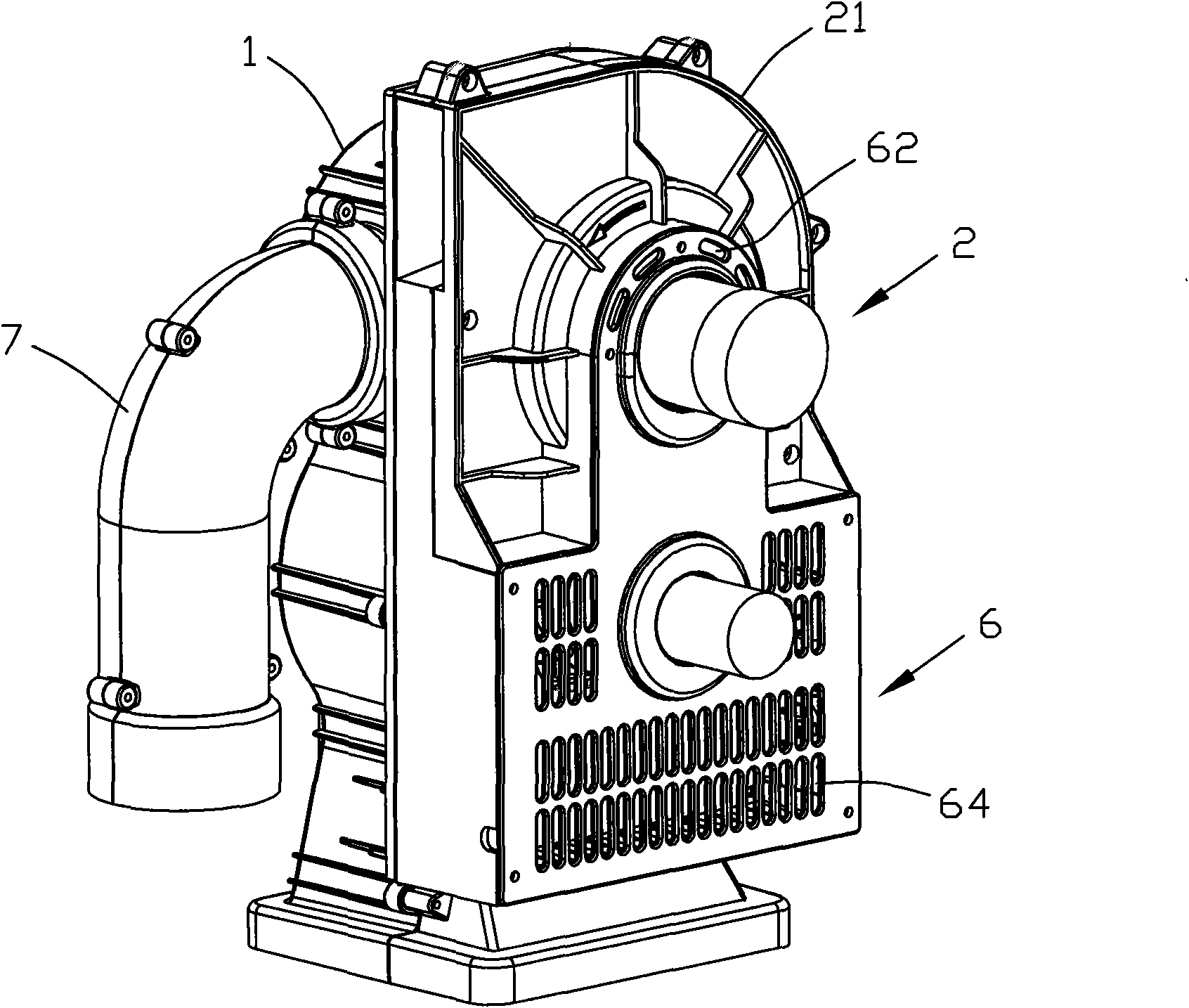

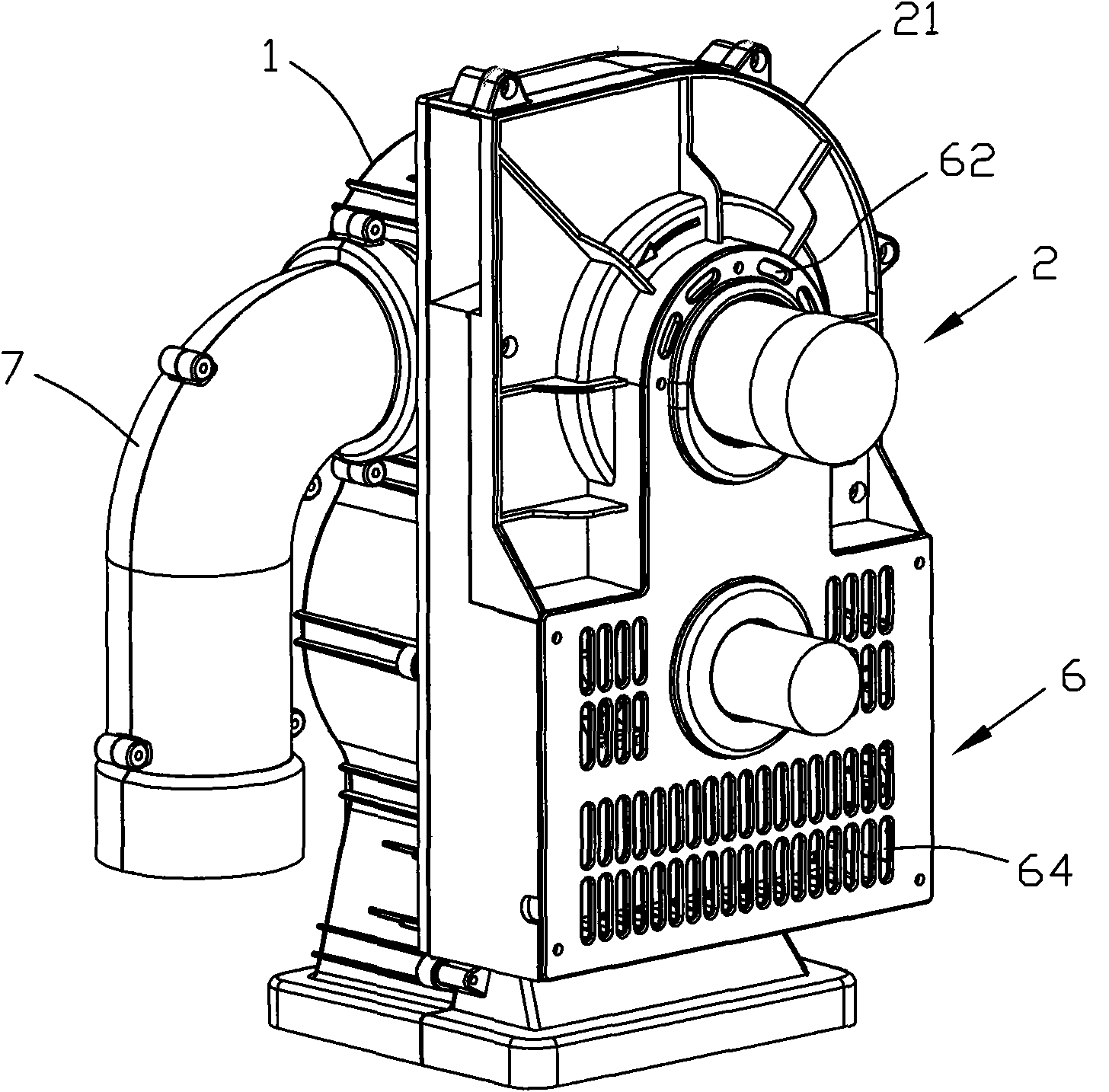

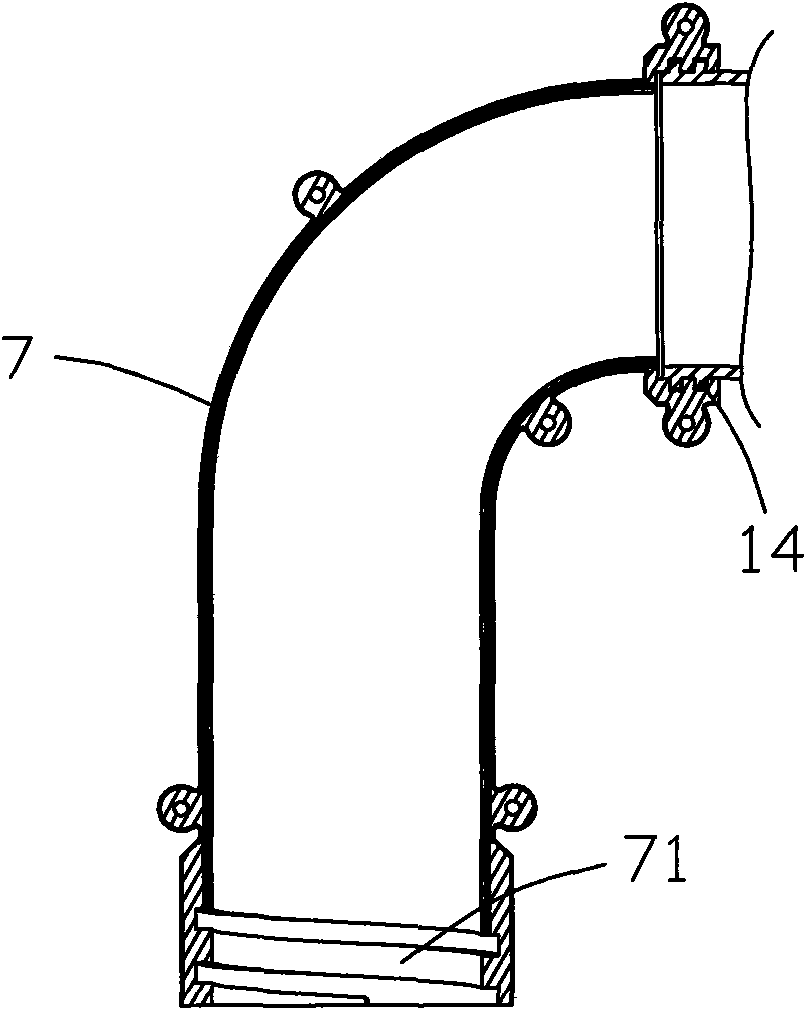

Novel suction system of piggyback cotton picker

InactiveCN101606459AImprove picking efficiencyLow broken wool contentPicking devicesFailure rateAtmospheric air

The invention discloses a novel suction system of a piggyback cotton picker, comprising a main case, a main air blower and a circuit board controlling the main air blower. A negative pressure cavity is formed in the main case when the main air blower rotates to work; an air inlet of the main blower is provided with a screen connected in a rotary way; an air lock is arranged between the negative pressure cavity and a cotton outlet at the bottom of the main case, and the air lock is tightly matched with the inner wall of the main case to separate the inside of the negative pressure cavity from atmosphere; the suction system is also provided with a heat dissipation structure comprising a cooling blade arranged on an output shaft of a main motor, a deflector hole for inspiration is arranged on the air blower case corresponds corresponding to the cooling blade, the air blower case is provided with an air outlet with a downward opening at the bottom of the cooling blade, and the bottom of the air blower case is provided with a ventilate grid communicated with atmosphere; the cooling blade sucks the air into the air blower case by the deflector hole, and air is exhausted to atmosphere by the air outlet and the ventilate grid. The invention has the advantages of high cotton picking efficiency, low broken fuzz content, low picking loss power, simple structure, reliable work and low failure rate.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD

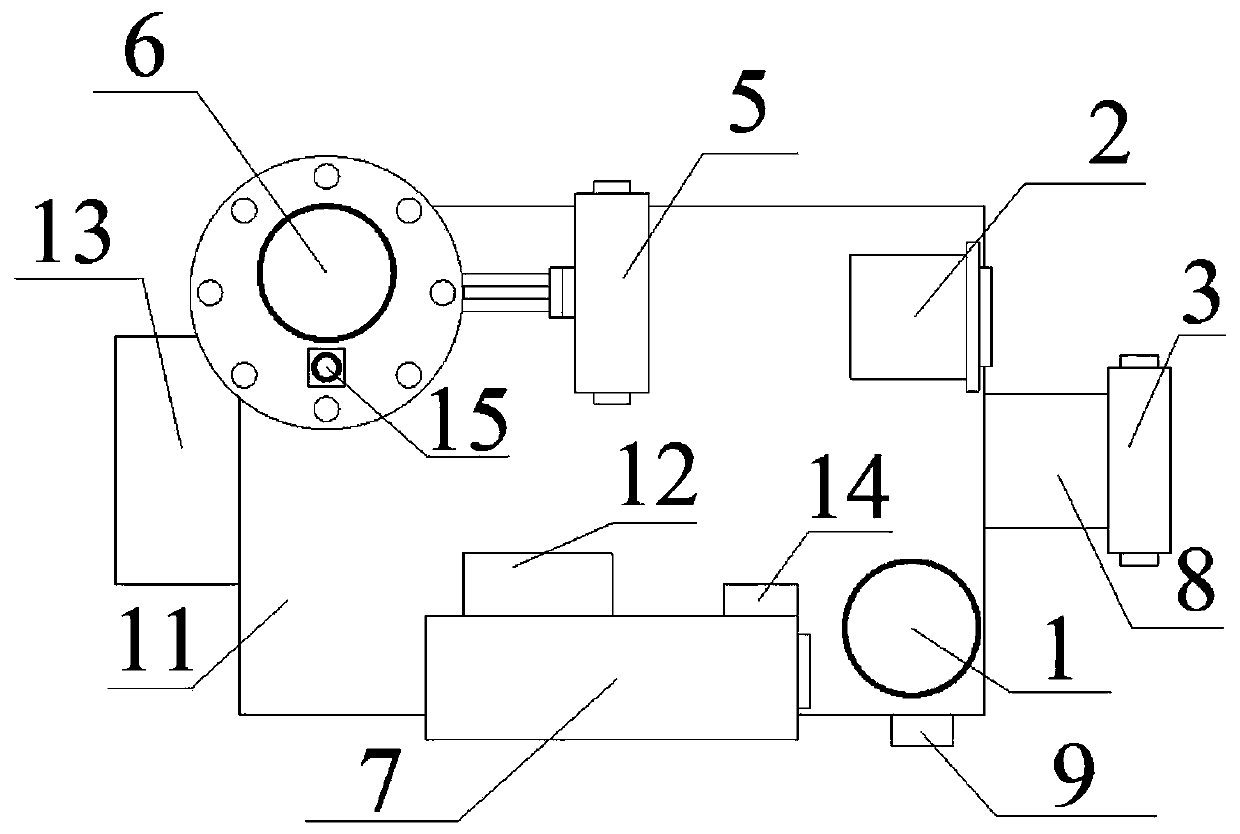

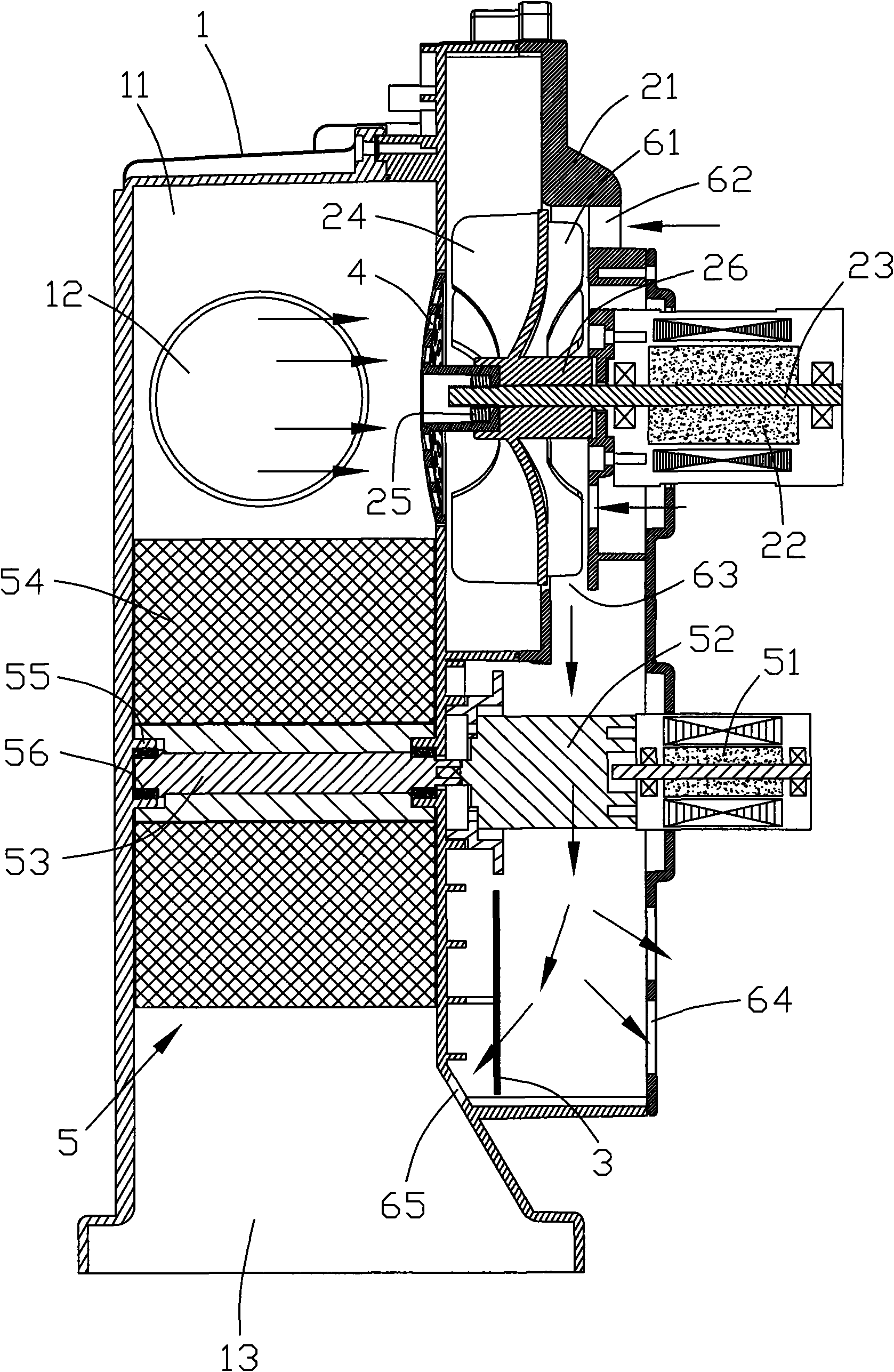

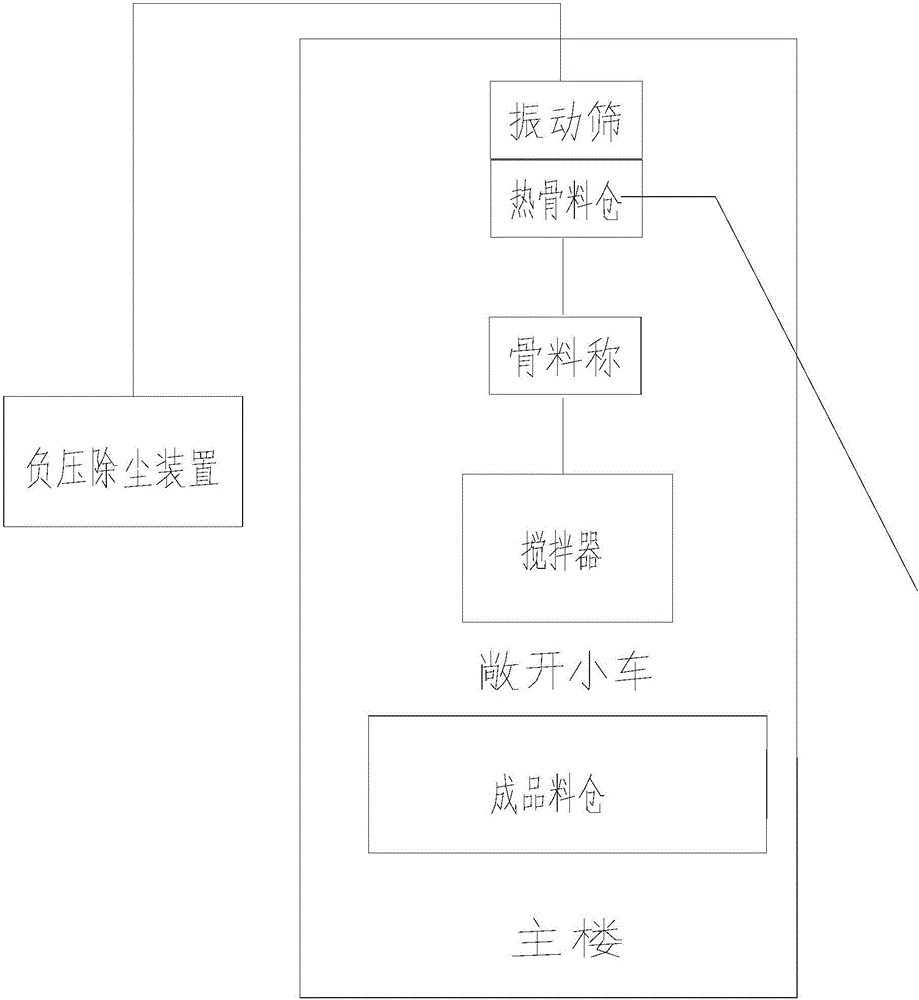

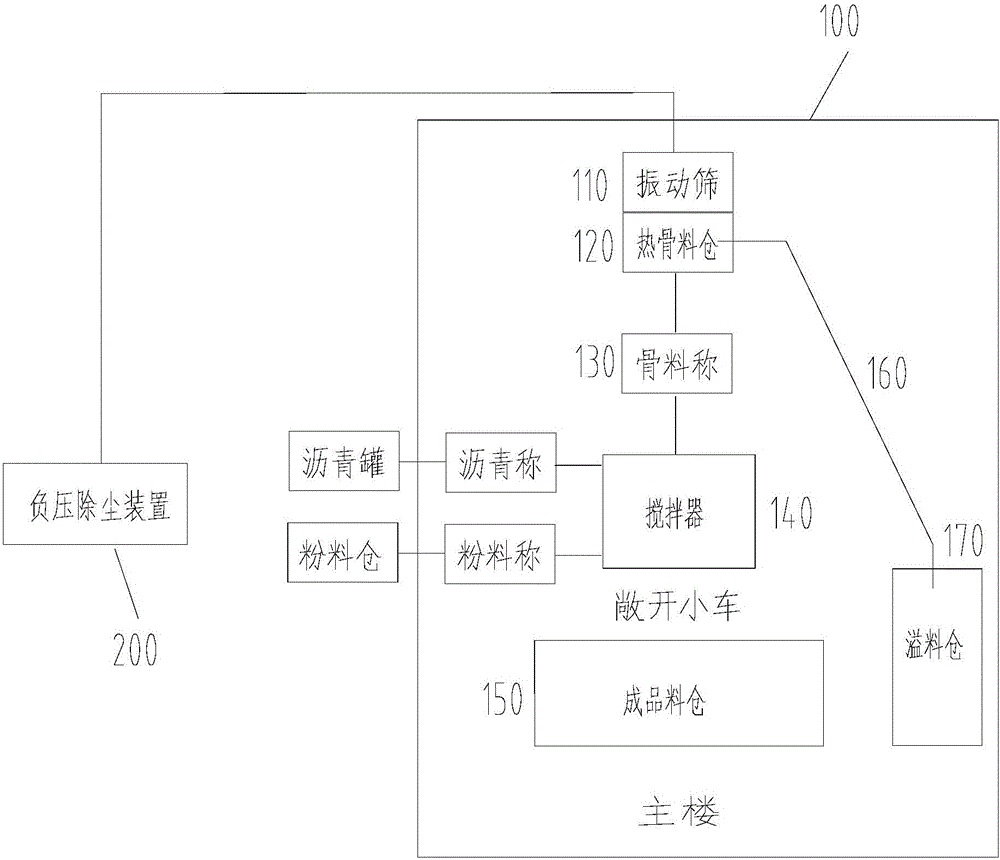

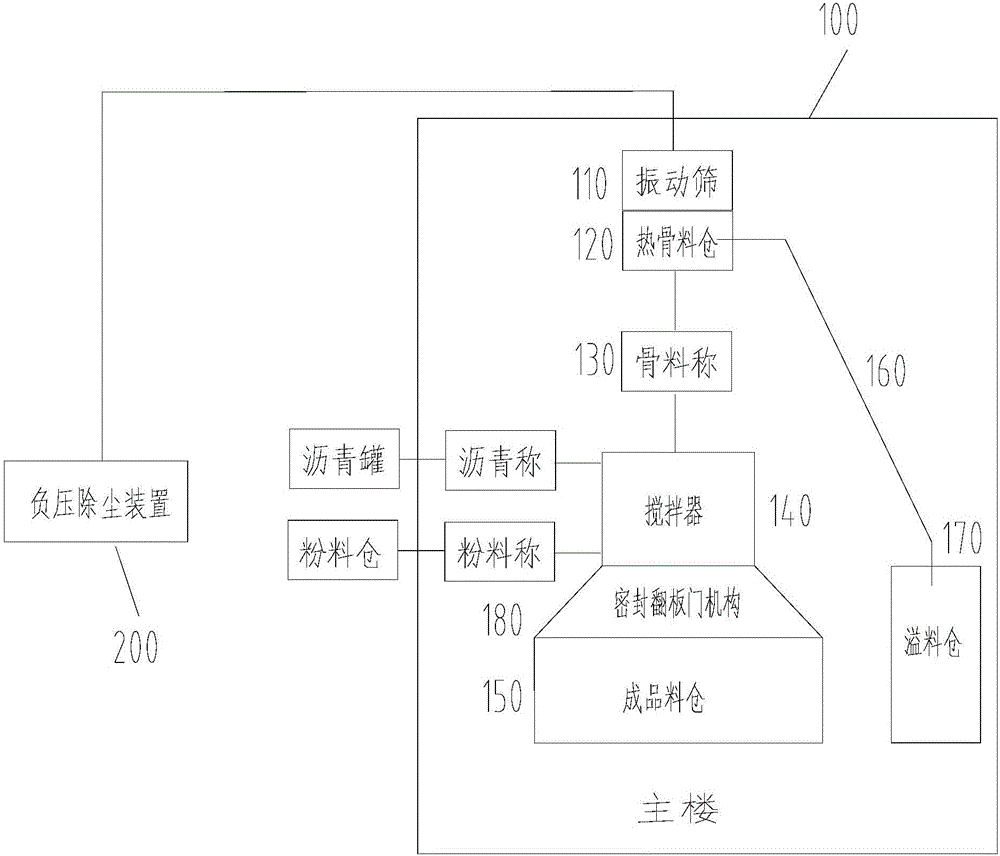

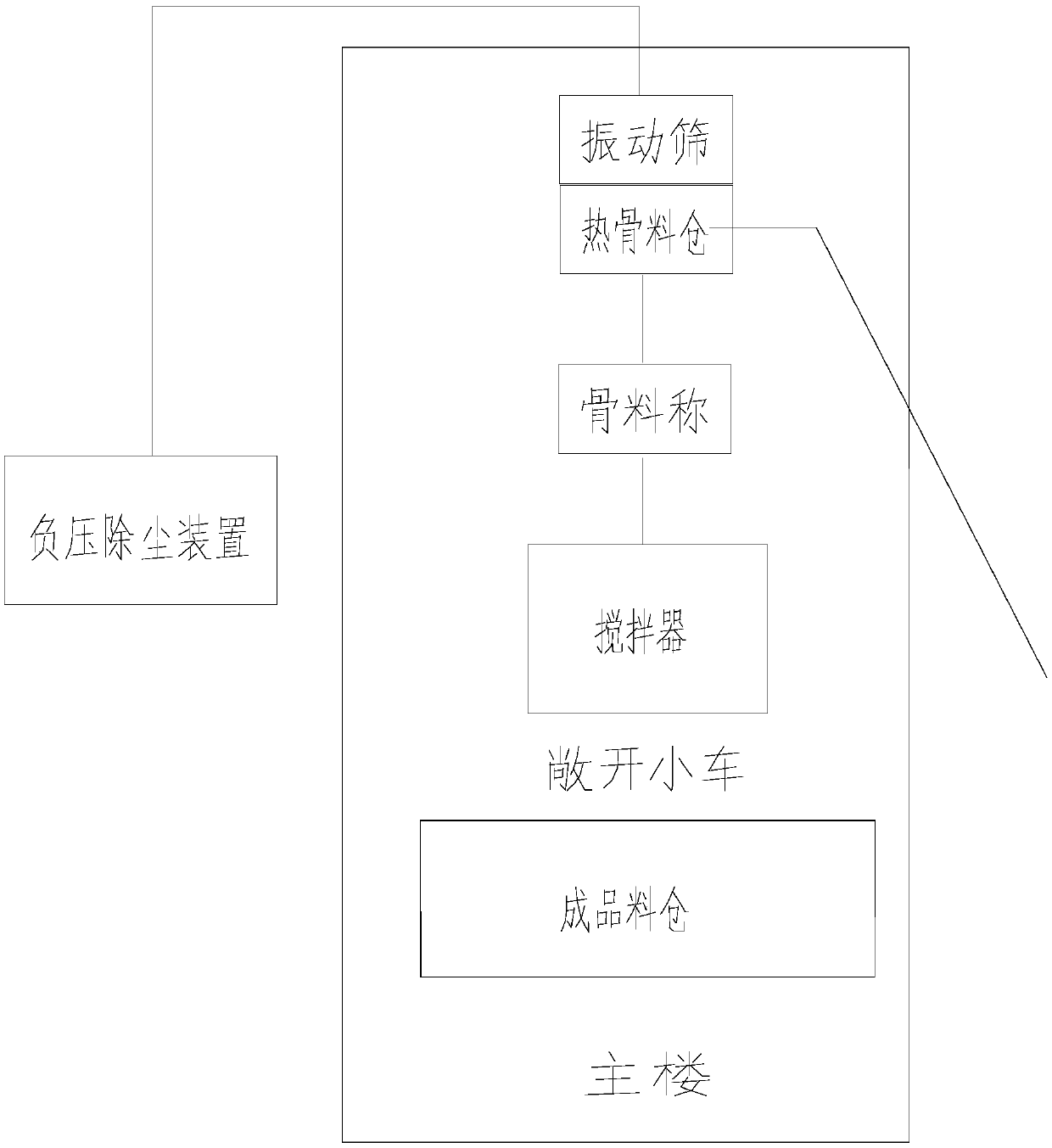

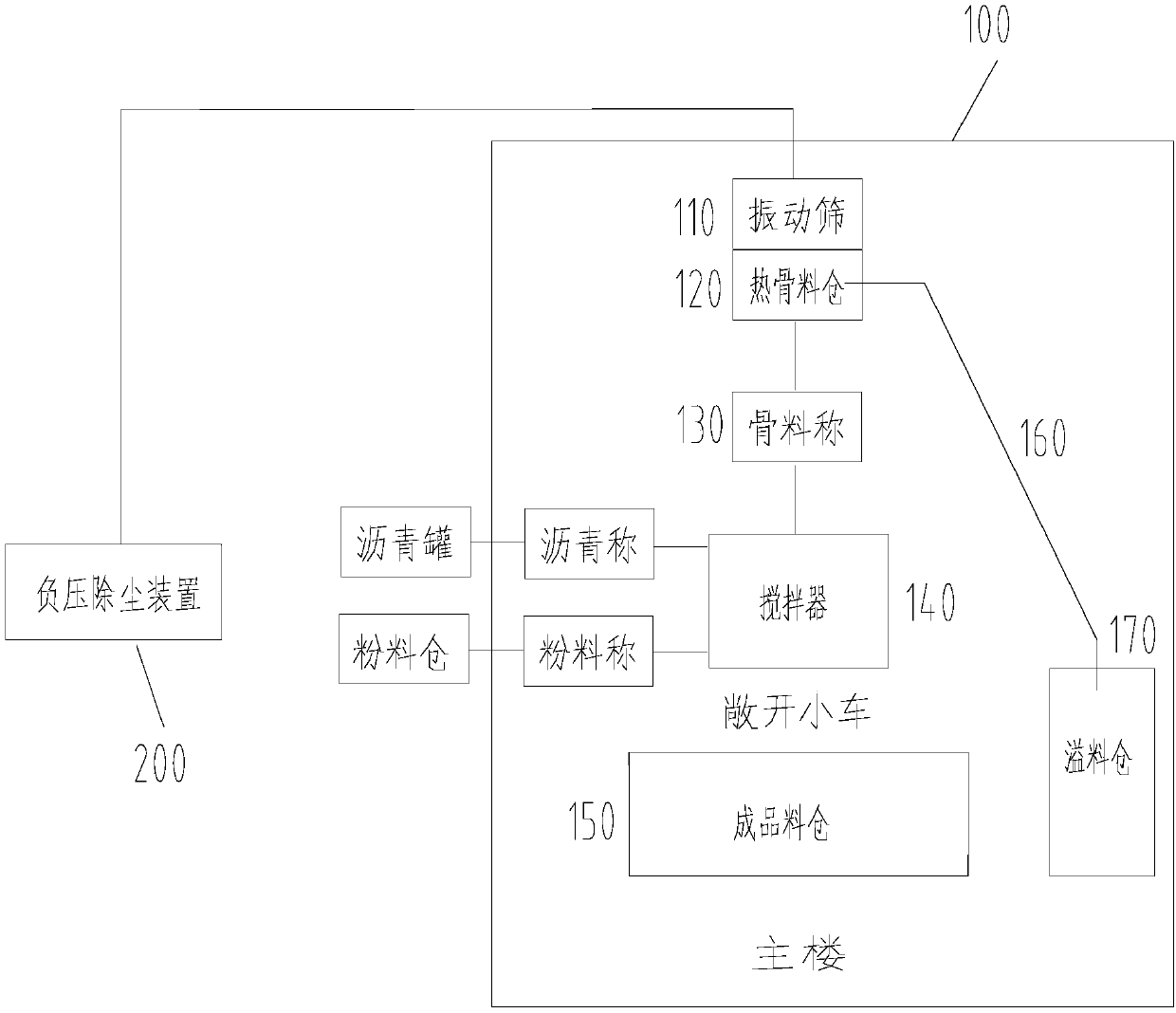

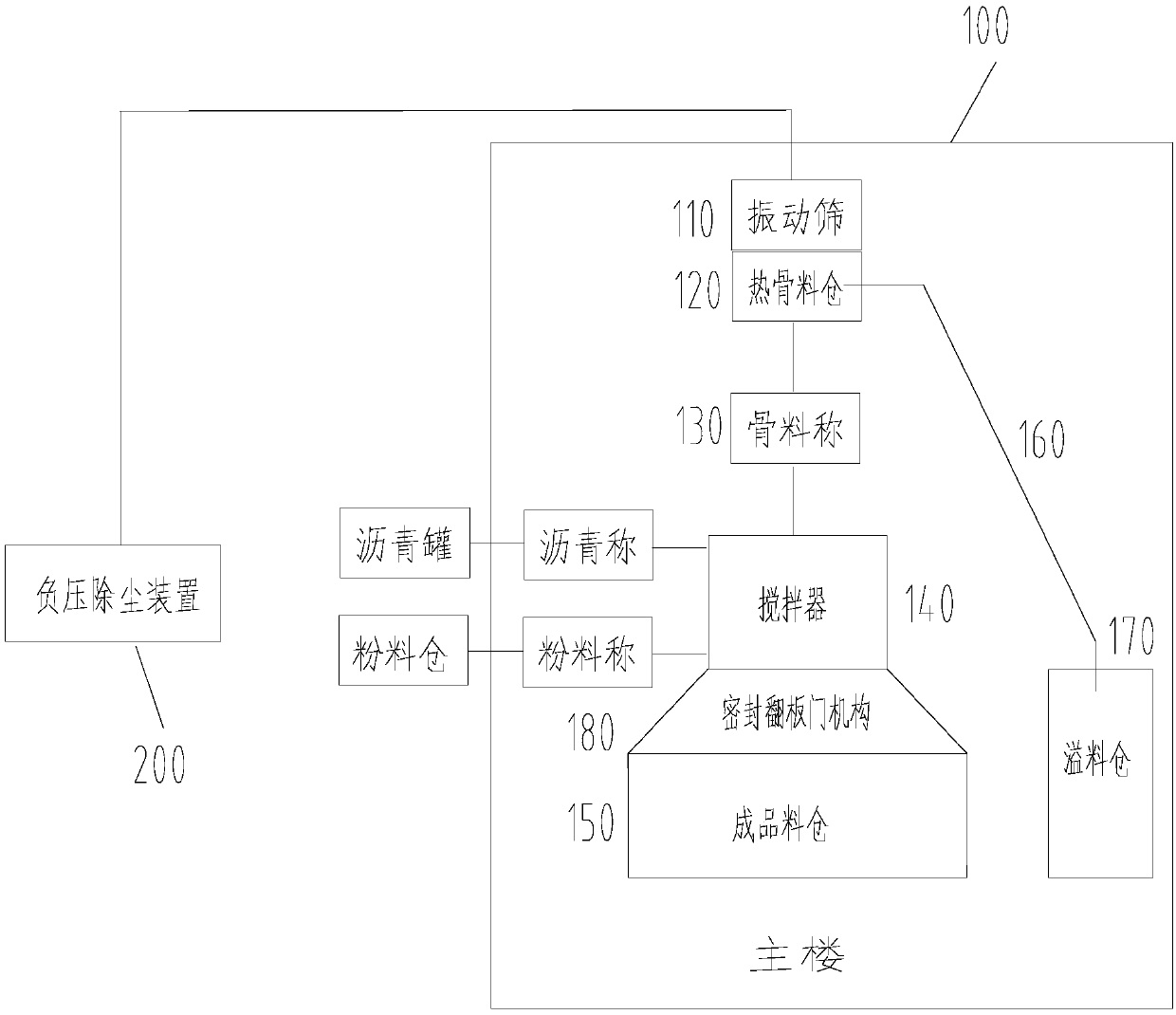

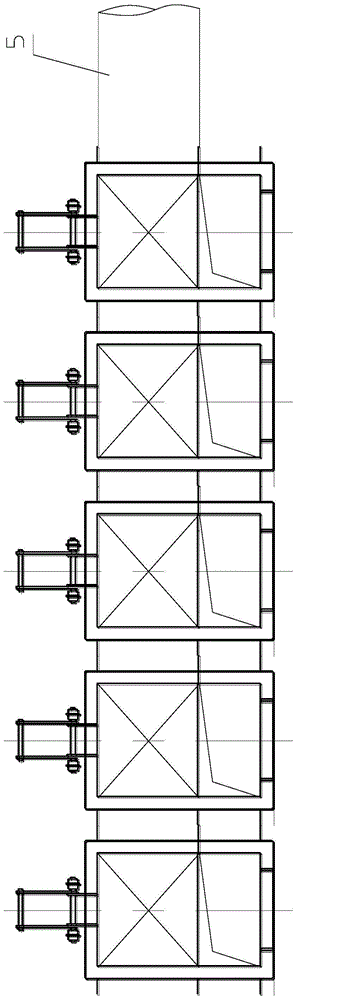

Bituminous mixing plant

ActiveCN106400654AReduce negative pressure lossReduce running wasteRoads maintainenceEngineeringAtmosphere

The invention discloses a bituminous mixing plant which comprises a main building and a negative pressure dust removal device, wherein the main building comprises a vibration sieve, a hot aggregate bin, an aggregate balance, a mixer and a finished product bin which are arranged in sequence from top to bottom; the negative pressure dust removal device communicates with the main building; the main building further comprises a material overflow pipe and a closed material overflow bin; and one end of the material overflow pipe communicates with the hot aggregate bin, and the other end of the material overflow pipe communicates with the material overflow bin. By the additional arrangement of the closed material overflow bin, the material overflow pipe is not arranged outside and connected with the atmosphere in a traditional way, but is connected with the closed material overflow bin, so that not only can the material overflow pipe be used as a material overflow channel, but also the material overflow pipe can form a closed space with the closed material overflow bin, and the closed space becomes a negative pressure channel in a replacing manner; negative pressure generated by the negative pressure dust removal device is retained in the whole main building, and communication between the negative pressure and the atmosphere via the hot aggregate bin and the material overflow pipe is avoided, so that the negative pressure loss and the operation waste of equipment are reduced to an extremely large extent; and moreover, constant negative pressure in the plant is guaranteed favorably, the influence of negative pressure fluctuation on metering is reduced, and the metering accuracy is improved.

Owner:SANY AUTOMOBILE MFG CO LTD

asphalt mixing plant

ActiveCN106400654BReduce negative pressure lossReduce running wasteRoads maintainenceEngineeringAsphalt

The invention discloses a bituminous mixing plant which comprises a main building and a negative pressure dust removal device, wherein the main building comprises a vibration sieve, a hot aggregate bin, an aggregate balance, a mixer and a finished product bin which are arranged in sequence from top to bottom; the negative pressure dust removal device communicates with the main building; the main building further comprises a material overflow pipe and a closed material overflow bin; and one end of the material overflow pipe communicates with the hot aggregate bin, and the other end of the material overflow pipe communicates with the material overflow bin. By the additional arrangement of the closed material overflow bin, the material overflow pipe is not arranged outside and connected with the atmosphere in a traditional way, but is connected with the closed material overflow bin, so that not only can the material overflow pipe be used as a material overflow channel, but also the material overflow pipe can form a closed space with the closed material overflow bin, and the closed space becomes a negative pressure channel in a replacing manner; negative pressure generated by the negative pressure dust removal device is retained in the whole main building, and communication between the negative pressure and the atmosphere via the hot aggregate bin and the material overflow pipe is avoided, so that the negative pressure loss and the operation waste of equipment are reduced to an extremely large extent; and moreover, constant negative pressure in the plant is guaranteed favorably, the influence of negative pressure fluctuation on metering is reduced, and the metering accuracy is improved.

Owner:SANY AUTOMOBILE MFG CO LTD

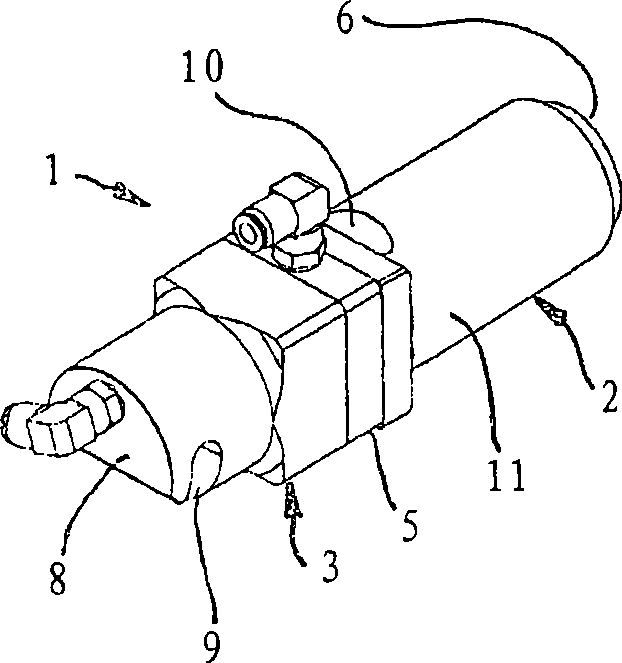

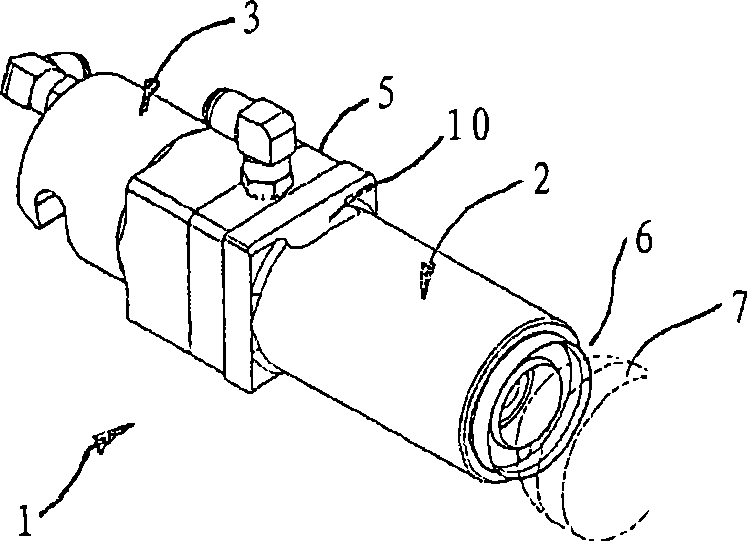

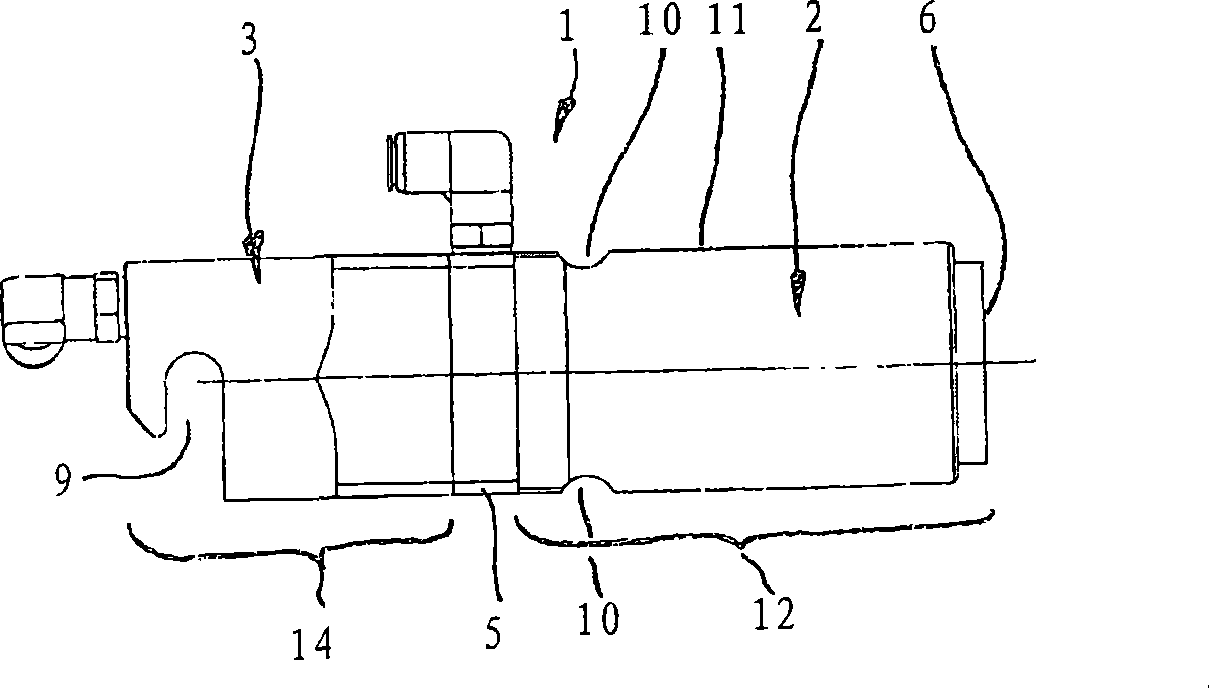

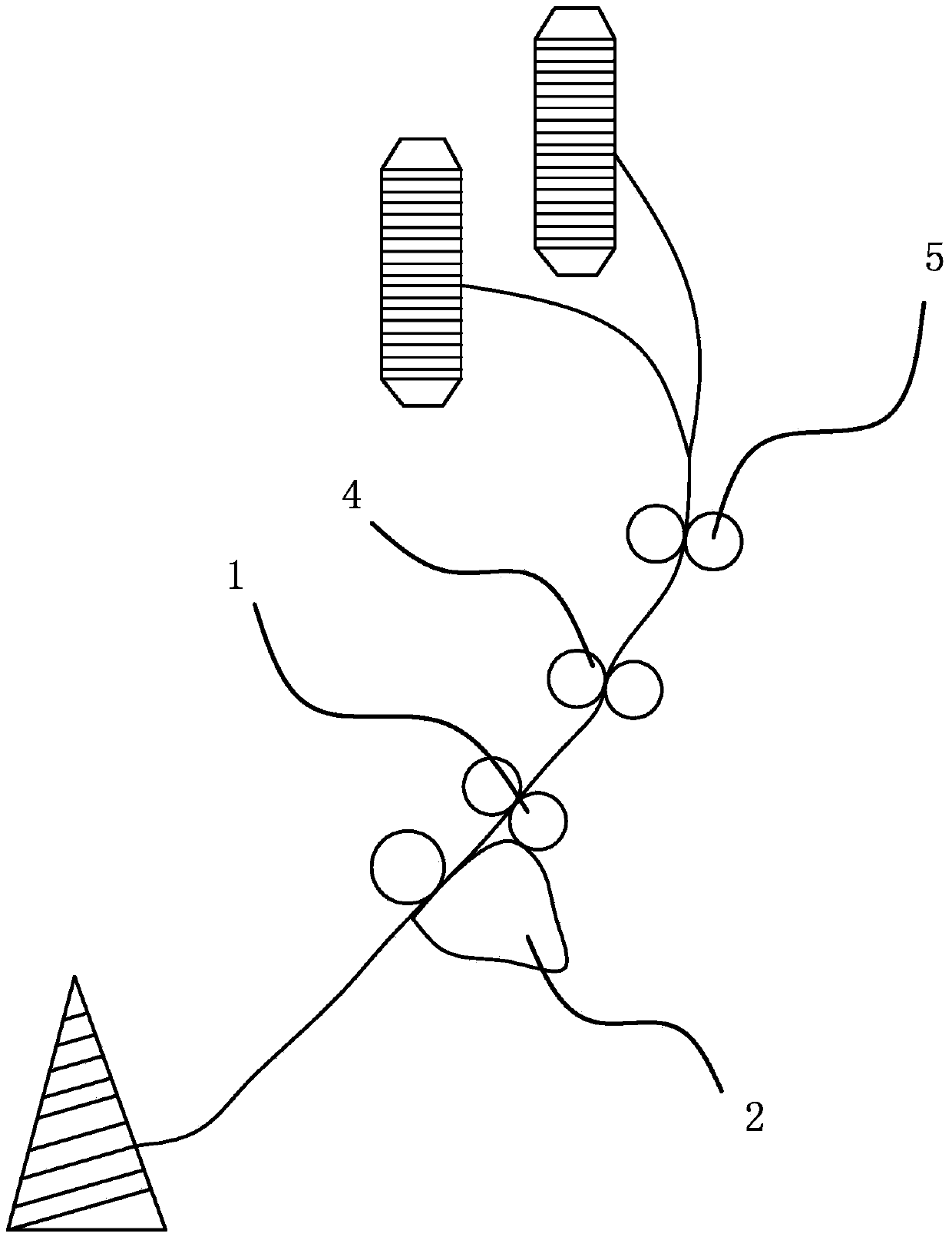

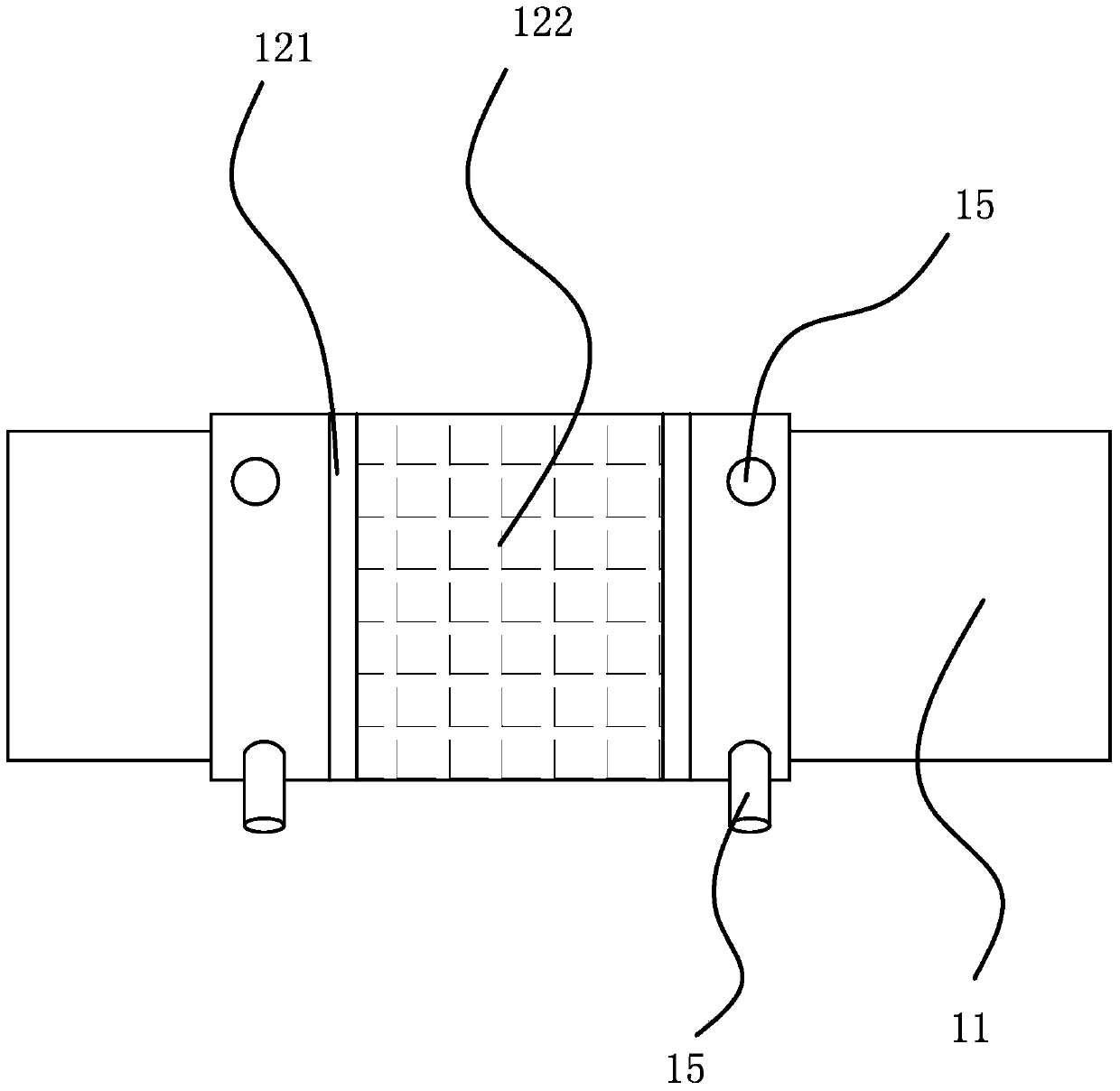

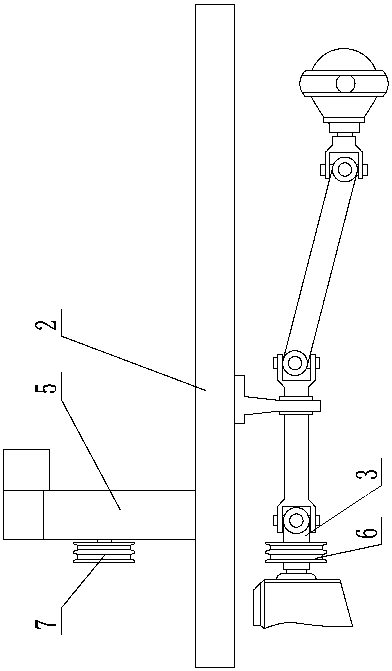

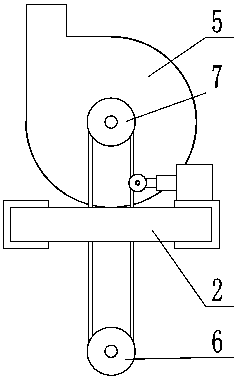

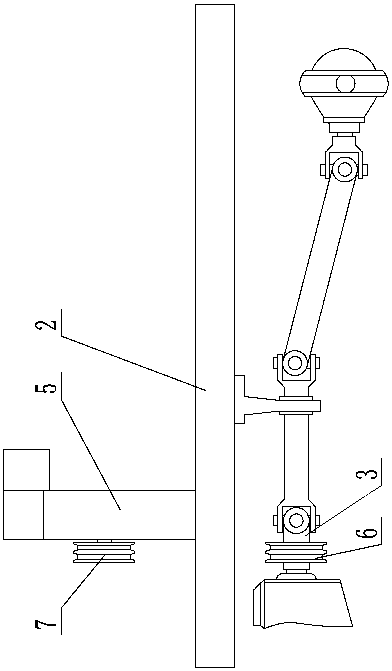

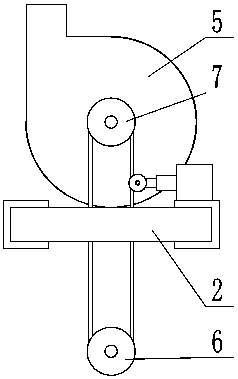

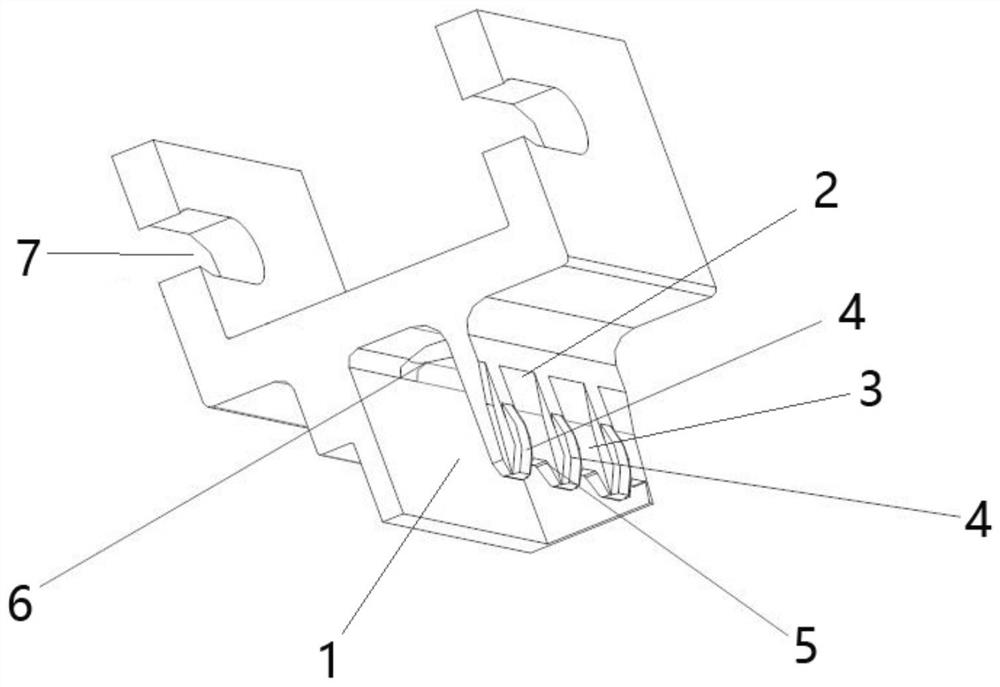

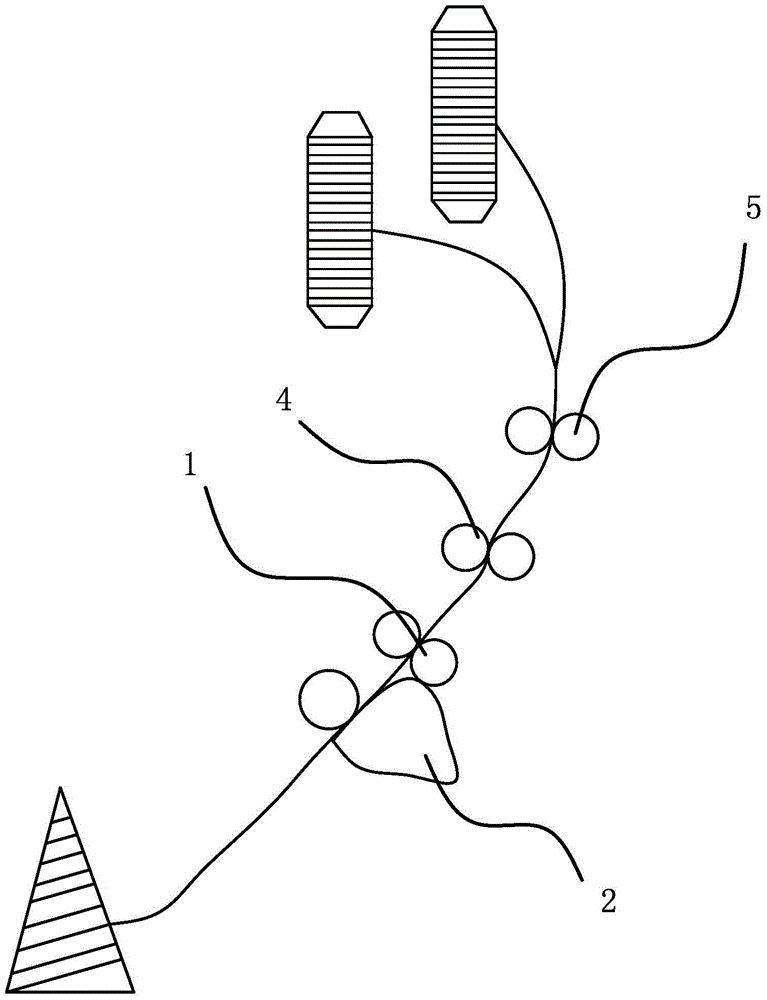

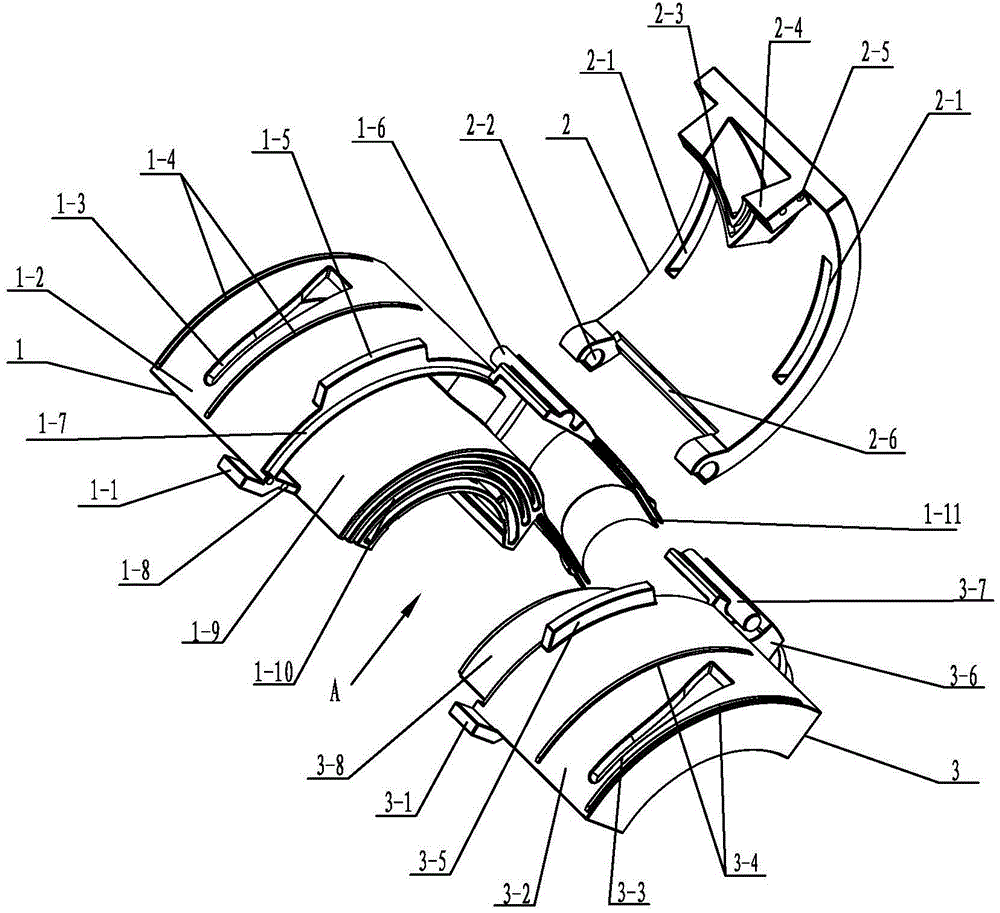

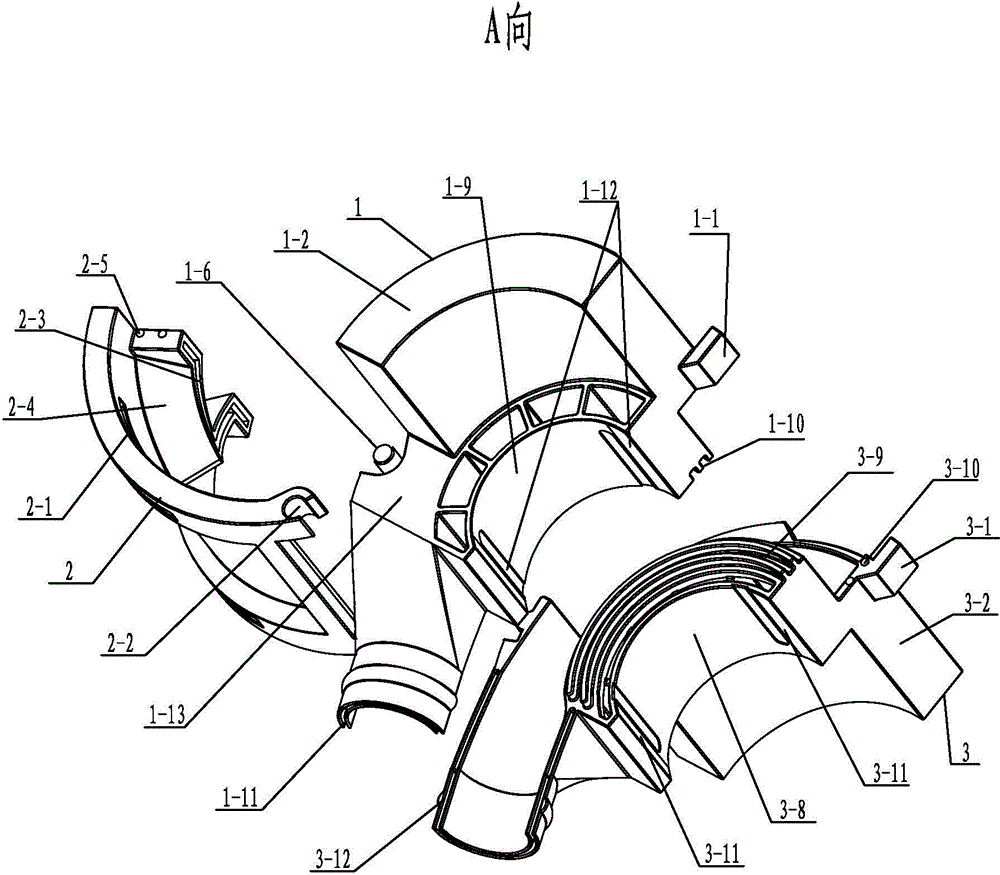

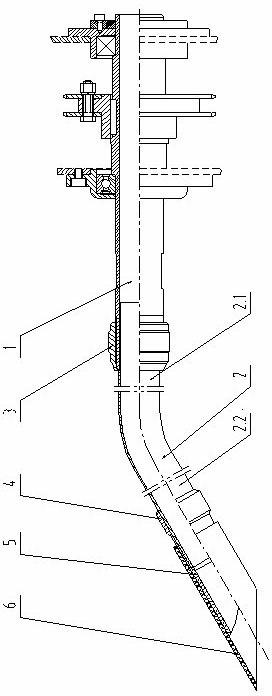

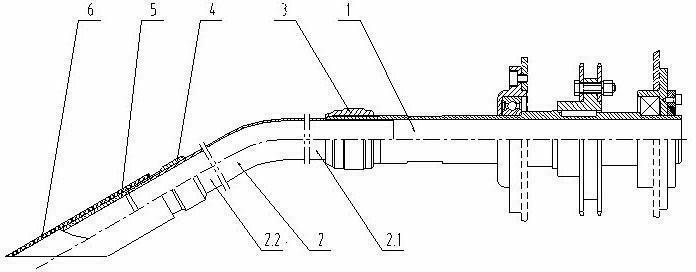

Balling-resisting quick change rotary suction nozzle device

ActiveCN102631815BAvoid knotsExtended service lifeDispersed particle filtrationEngineeringFilter material

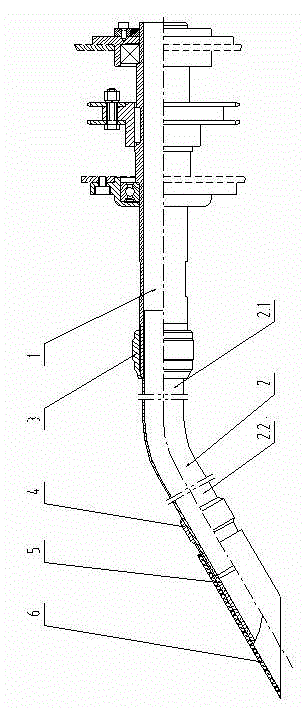

The invention relates to a balling-resisting quick change rotary suction nozzle device, belonging to the technical field of spinning machines. The balling-resisting quick change rotary suction nozzle device comprises a horizontally arranged main shaft (1), wherein a suction arm (2) is inserted into the end part of the main shaft (1) and comprises a horizontal section (2.1) and an inclined section (2.2), the end part of the inclined section (2.2) of the suction arm (2) is connected with a suction nozzle (5), and a suction nozzle end surface of the suction nozzle (5) is parallel to the central line of the main shaft (1). According to the balling-resisting quick change rotary suction nozzle device disclosed by the invention, the suction nozzle and the suction arm are of quick connection structures and are very convenient to replace, and the lengths of the suction nozzle and the suction arm can be configured as required; a rubber suction nozzle is sleeved on the suction nozzle so that the suction nozzle does not generate static electricity with a filtering material so as to be capable of effectively preventing the filtering material from balling and hardening and prolonging the service life of the filtering material. The horizontal section and the inclined section of the suction arm are bent into 120 degrees, a diameter range is set, the area of a suction nozzle is large, and the loss of negative pressure is less.

Owner:JIANGSU JINGYA ENVIRONMENT TECH

Novel suction system of piggyback cotton picker

InactiveCN101606459BImprove picking efficiencyLow broken wool contentPicking devicesFailure rateAir blower

The invention discloses a novel suction system of a piggyback cotton picker, comprising a main case, a main air blower and a circuit board controlling the main air blower. A negative pressure cavity is formed in the main case when the main air blower rotates to work; an air inlet of the main blower is provided with a screen connected in a rotary way; an air lock is arranged between the negative pressure cavity and a cotton outlet at the bottom of the main case, and the air lock is tightly matched with the inner wall of the main case to separate the inside of the negative pressure cavity from atmosphere; the suction system is also provided with a heat dissipation structure comprising a cooling blade arranged on an output shaft of a main motor, a deflector hole for inspiration is arranged on the air blower case corresponds corresponding to the cooling blade, the air blower case is provided with an air outlet with a downward opening at the bottom of the cooling blade, and the bottom of the air blower case is provided with a ventilate grid communicated with atmosphere; the cooling blade sucks the air into the air blower case by the deflector hole, and air is exhausted to atmosphere bythe air outlet and the ventilate grid. The invention has the advantages of high cotton picking efficiency, low broken fuzz content, low picking loss power, simple structure, reliable work and low failure rate.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD

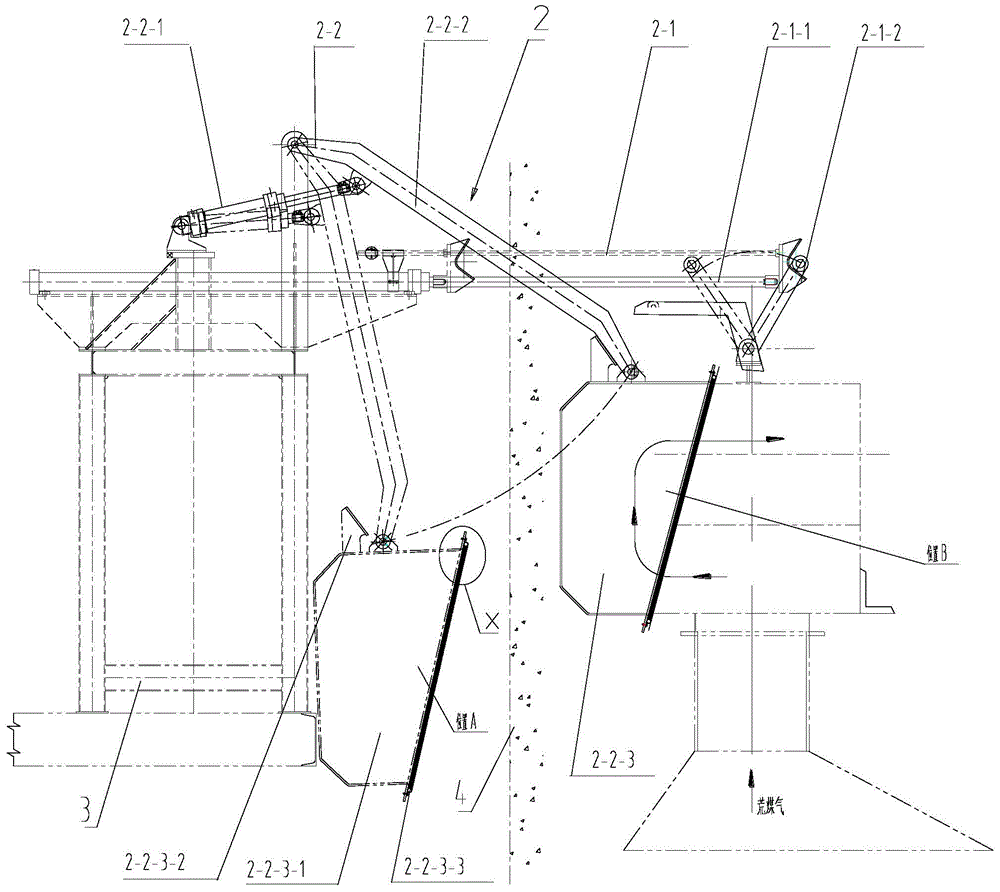

Connecting device of furnace end smoke collection pipeline

ActiveCN103666492BReduce pollutionPass smoothlyCharging devicesDistillation gas withdrawalFiberEngineering

The invention discloses a connecting device of a furnace end smoke collection pipeline, relates to a coal charging smoke collection device of a tamping coke furnace, and solves the technical problems of inaccuracy for butting, poor sealing effect and incapability of normally collecting furnace end smoke in a conventional blind sleeve. The connecting device comprises a flap valve switching-on device and a blind sleeve butting device, and is used for communicating an upper pipeline with a lower pipeline; a flap valve drive oil cylinder of the flap valve switching-on device is connected with a push rod; a blind sleeve butting drive oil cylinder of the blind sleeve butting device is hinged to a swing arm, and the other end of the swing arm is connected with a blind sleeve; a vertical limiting block is mounted at the joint between a blind sleeve body and the swing arm, and a ceramic fiber blanket sealing ring is arranged on the edge of a butting hole of the blind sleeve body. The connecting device is used for connecting the upper and lower pipelines of the furnace end smoke collection pipeline and has the advantages of space saving, simple structure, accuracy for alignment, good sealing effect and the like.

Owner:TAIYUAN HEAVY IND

Suction type precision seed bunch planting device

InactiveCN101766078BLarge internal spaceIncrease heightSeed depositing seeder partsRegular seed deposition machinesAgricultural scienceAgricultural engineering

The invention relates to an agricultural seeding device, in particular to a suction type precision seed bunch planting device. The suction type precision seed bunch planting device mainly comprises a seed tank (26), a suction type seed sorter, a roller, a negative pressure air suction pipe (6), a speed shifting mechanism and a seed receiving and delivering device, wherein the suction type seed sorter is arranged in the roller and communicated with the negative pressure air suction pipe (6); a seed delivering box (30) is arranged between a seed outlet of the suction type seed sorter and a ducknozzle (42); a main shaft (4) of the roller is a hollow pipe; a main shaft (9) of the suction type seed sorter is arranged in the hollow pipe-shaped main shaft (4) of the roller; one end of the main shaft (9) of the suction type seed sorter is coupled to the suction type seed sorter through a bearing (8.1) and drives a seed suction disk (33), and the other end of the main shaft (9) of the suctiontype seed sorter passes through a sealing bearing (8) in the main shaft (4) of the roller; the main shaft (4) of the roller and the main shaft (9) of the suction type seed sorter are in speed-shifting connection through a gear or a chain or a notched belt. The suction type precision seed bunch planting device has the advantages of increasing the inner space of the roller as much as possible, increasing the height of the seed delivering box simultaneously, conveniently regulating the rotating speed ratio of the roller to the seed absorption box according to the agronomic requirements, and greatly improving the seeding speed while seeding accurately. Due to the unique transmission structure, the suction type precision seed bunch planting device is compact and steady, and the fault rate is reduced obviously under the environment of worse working condition.

Owner:陈恒

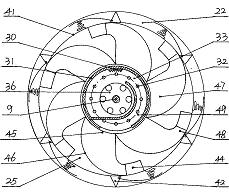

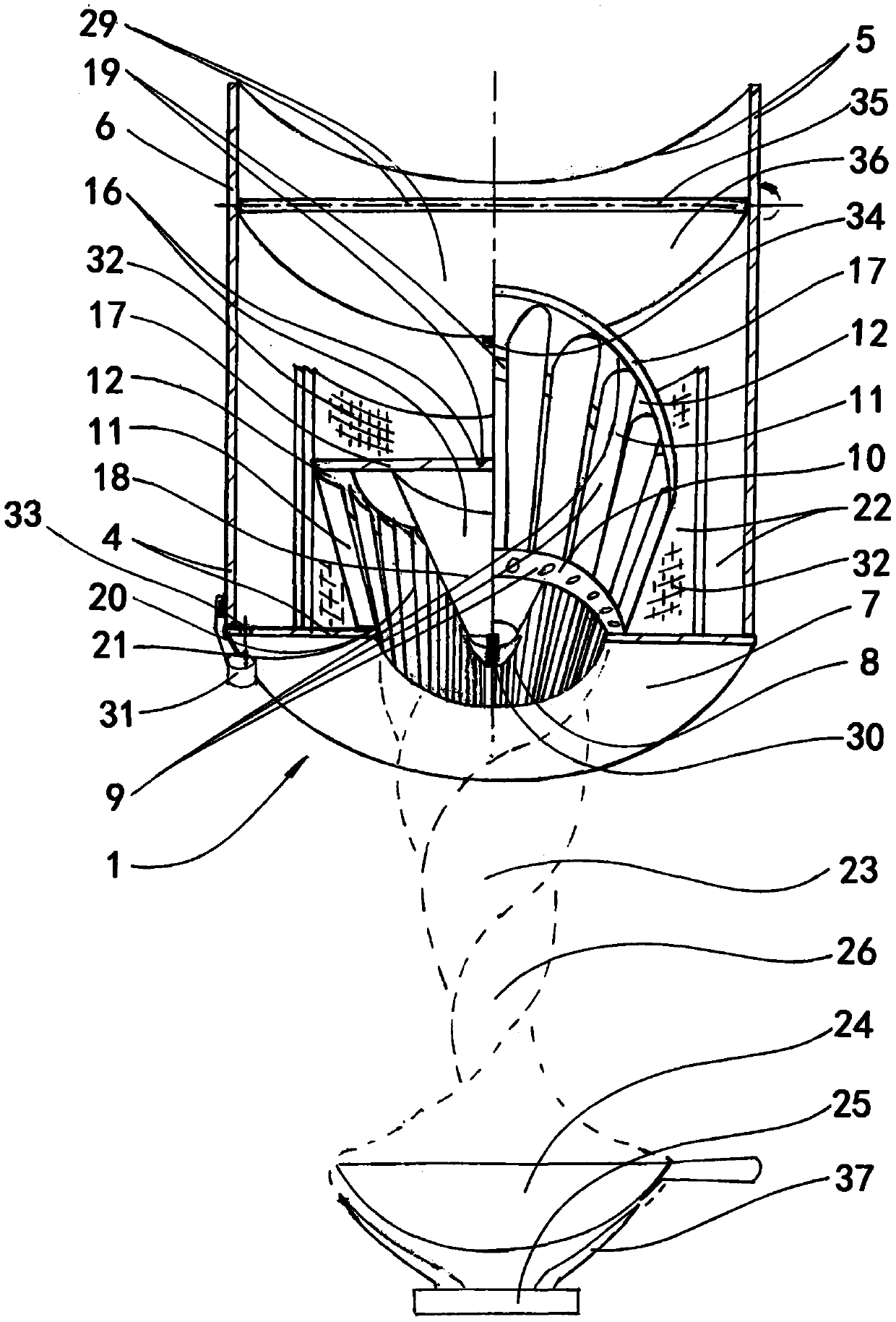

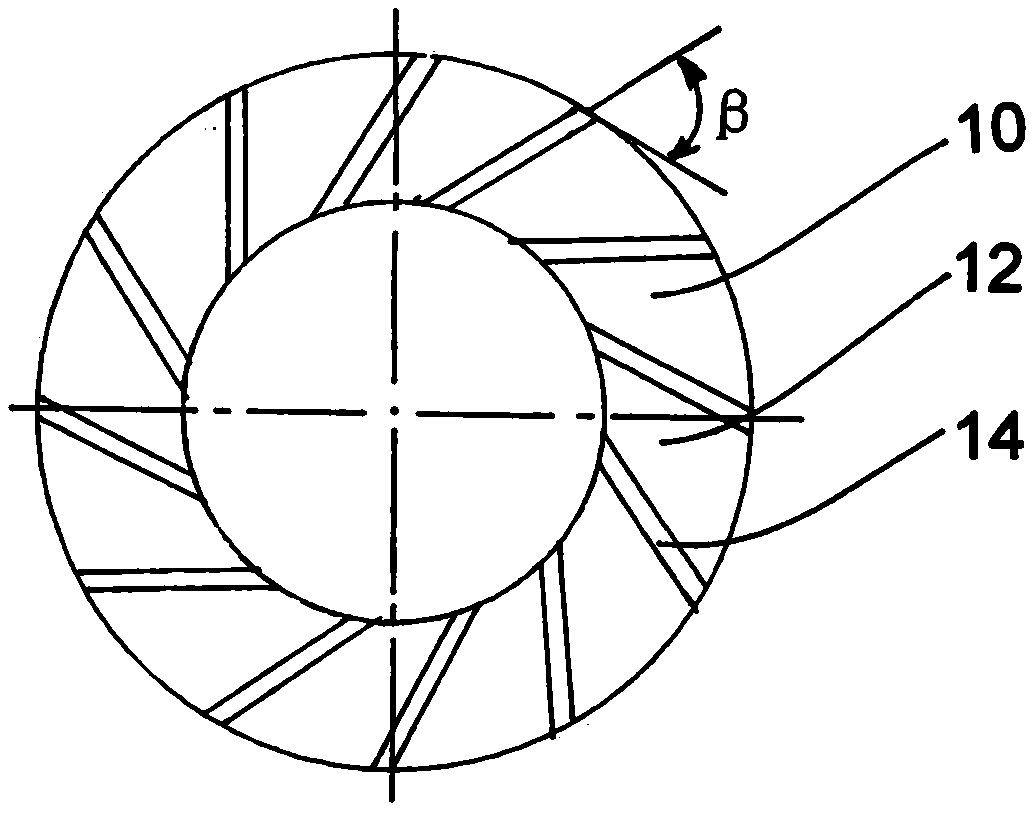

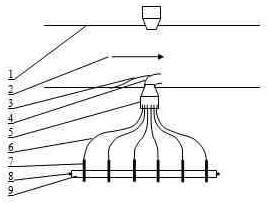

Tornado-type suction nozzle and range hood thereof

PendingCN110793081AReduce negative pressure lossLong distanceDomestic stoves or rangesLighting and heating apparatusExhaust fumesImpeller

The invention relates to a tornado-type suction nozzle and a range hood thereof. The tornado-type suction nozzle and the range hood thereof are characterized in that an air inlet (8) of a shell (4) isconcentrically connected with an impeller lower disk (10); an impeller upper disk (12)and an impeller tongue plate (16) are concentrically fixed; a connecting port (5) of the shell (4) is connected with an oil exhaust fume pipe (3) or a fan (2); the impeller upper disk (12) is larger than the impeller lower disk (10), and the two ends of a unidirectional blade (11) are evenly fixed to the impeller upper disk (12) and the impeller lower disk (10) separately; the impeller upper disk (12) is provided with a tapered shell tongue (18); the cross section of the shell tongue (18) and a gap (20) of the unidirectional blade (11) gradually decreases from top to bottom; and an impeller (9) is a non-rotating cyclone guide wheel, due to the suction by the fan (2), a negative pressure area tornado (23)which is in a constricted funnel shape and perpendicular to the horizontal surface is formed under the tornado-type nozzle (1), and extends to the inner bottom of a pot (24) and sucks oil fume away.The range hood has a long suction distance, large suction power, concentrated negative pressure, simple structure and low noise.

Owner:杨富云

Intermediate storage tank and sewage source separation system based on negative pressure

ActiveCN101363241BIncrease flow rateSave powerSewerage structuresClimate change adaptationInternal pressureControl signal

The invention relates to an intermediate storage tank for collecting domestic sewage and also relates to a domestic sewage source separation system under negative pressure adopting the intermediate storage tank. The intermediate storage tank comprises a tank body, an induction valve, a control valve, a storage tank sewage discharge negative pressure valve and a microprocessor, wherein, the tank body is provided with an induction tube and a storage tank sewage discharge pipe, the upper middle part of the tank body is provided with a sewage inlet and the upper part of the tank body is provided with one or a plurality of air inlets, the lower end ports of the induction tube and the storage tank sewage discharge pipe are positioned inside the tank body, the upper part of the inner cavity of the induction tube is communicated with the induction valve by an internal pressure connecting mouth, an induction signal output route of the induction valve is connected with a signal input terminal of the microprocessor, a control signal output line of the microprocessor is connected with a control route of the control valve, a negative pressure control pipeline of the control valve is connected with a negative pressure control cavity of the storage tank sewage discharge negative pressure valve, and the storage tank sewage discharge pipe is connected with a negative pressure sewage discharge pipeline by the storage tank sewage discharge valve. The domestic sewage source separation system comprises a plurality of the intermediate storage tanks and one or a plurality of sewage collection tanks, and is provided with a uniform negative pressure source. The domestic sewage source separation system is beneficial to reducing power consumption and realizing the source separation of the domestic sewage.

Owner:ENVIROSYST BEIJING ENVIRONMENTAL ENG & TECH CO LTD

Range hood with movable smoke deflector and control method thereof

ActiveCN111102621BAchieve liftingReduce negative pressure lossDomestic stoves or rangesLighting and heating apparatusEngineeringSmoke hood

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

A sanitation vacuum cleaner

ActiveCN105780699BReduce input powerReduce energy consumptionGas treatmentDispersed particle filtrationVehicle frameEngineering

The invention provides a dust-collection sanitation vehicle. The dust-collection sanitation vehicle comprises a cab, a vehicle frame, an engine power output shaft and a compartment. A draught fan is installed on the vehicle frame. A driving belt wheel is installed on the engine power output shaft. A driven belt wheel is installed on a draught fan spindle. The driving belt wheel is in transmission connection with the driven belt wheel through a belt. The lower portion of the vehicle frame is connected with a main dust collection pipe. The main dust collection pipe is provided with a dust collection port. The main dust collection pipe is connected with an air suction port of the draught fan through a telescopic hose. The compartment comprises a base plate, side plates, a front plate and a tail door. A first dust filtering plate assembly and a second dust filtering plate assembly are detachably connected to the interior of the compartment. The first dust filtering plate assembly is vertically arranged on the tail of the compartment and spaced from the tail door by a certain distance. The second dust filtering plate assembly is horizontally arranged at the top of the compartment. A dust collection cavity used for collecting dust is defined by the base plate, the side plates, the front plate, the first dust filtering plate assembly and the second dust filtering plate assembly. An air inlet communicating with the dust collection cavity is formed in the compartment. An air outlet of the draught fan is connected with the air inlet in the compartment.

Owner:邯郸极驰汽车股份有限公司

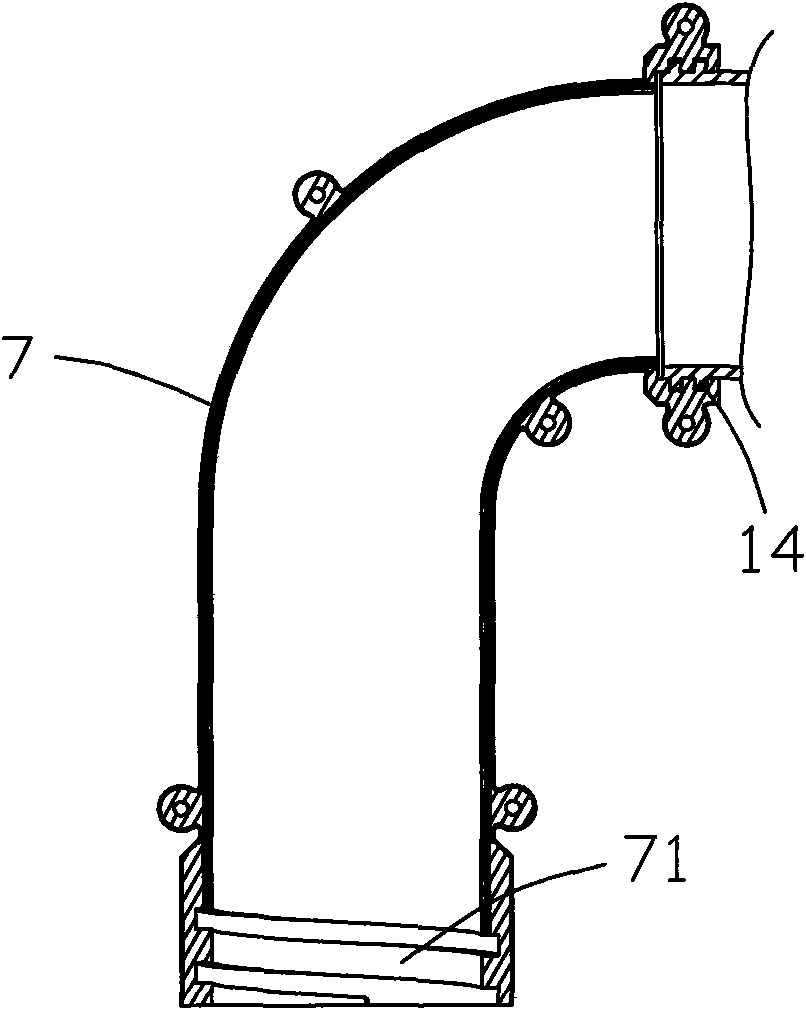

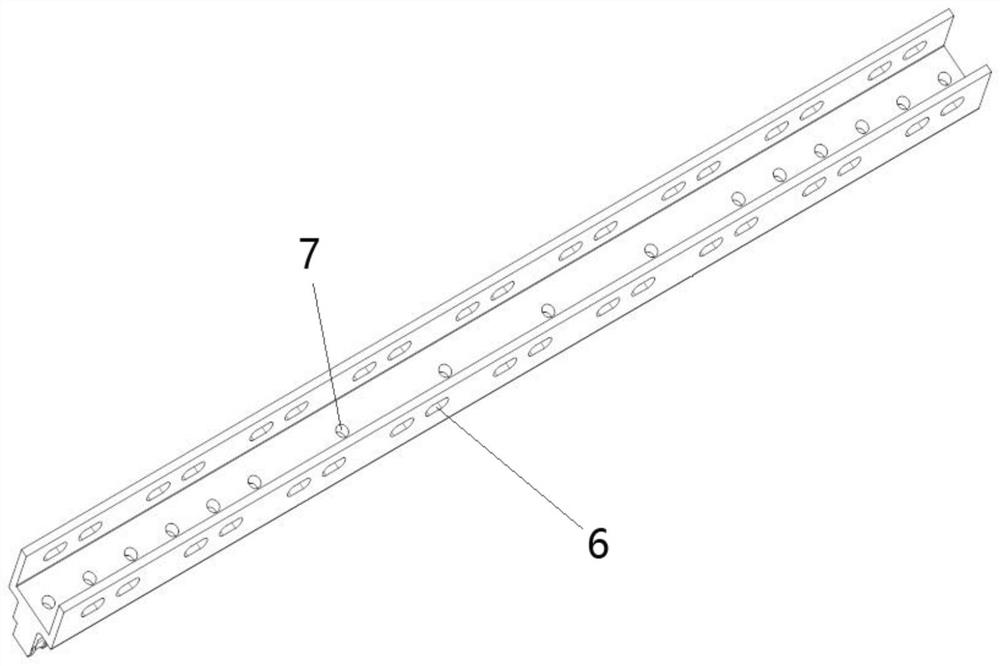

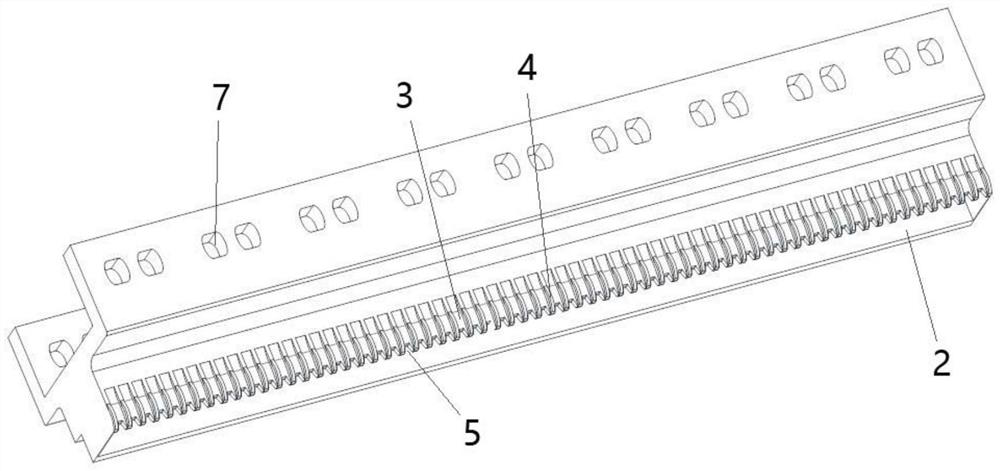

Cotton suction branch pipe of spinning frame

InactiveCN112779637AEasy to connectReduce negative pressure lossTextiles and paperSpinningAgricultural engineering

The invention provides a cotton suction branch pipe of a spinning frame. According to the technical scheme of the cotton suction branch pipe of the spinning frame, a plastic round pipe with a smooth inner wall is adopted as the branch pipe, a connecting method of the branch pipe, a branch pipe nozzle and a main air suction pipe is improved, air resistance is reduced, 90-degree airflow disturbance of the branch pipe and the main air suction pipe are eliminated from multiple aspects, the whole branch pipe and connecting points thereof have no cotton accumulating and hanging positions, the airflow transmission efficiency of a cotton suction system is improved, the negative pressure loss is reduced, the maintenance performance is improved, and the device is suitable for new machine application and transformation of stock spinning frames.

Owner:倪远

Cleaning scraping strip with water passing structure

PendingCN114468882AGuaranteed normal operationHigh hardnessCarpet cleanersFloor cleanersEngineeringEnvironmental geology

The cleaning scraping strip with the water passing structure comprises a dirt collecting device with a dirt collecting groove formed in the bottom, the front side face of the dirt collecting groove is composed of a scraping strip, the dirt collecting groove is connected with a dirt suction assembly capable of generating negative pressure, a dirt collecting channel is formed in the front side face of the scraping strip, and when the scraping strip is pressed downwards to advance, the lower end of the scraping strip is bent backwards; the dirt collecting channel is just located at the lower end of the bent scraping strip and communicates the dirt collecting groove with the space in front of the scraping strip. The problems that when the scraping strip is pressed downwards to move front and back, the flow guide channel is blocked, and water absorption of the scraping strip fails are solved.

Owner:江苏飞慕生物科技有限公司

Double-hole air suction general energy-saving seed metering device for soybean and corn

InactiveCN110073775BIncrease general seeding effectImprove adsorption capacitySingle grain seedersSeederAgricultural engineering

The dual-hole air-suction universal energy-saving seed metering device for soybeans and corn belongs to the technical field of agricultural machinery. The edge of the seed metering device in the present invention is provided with a double-suction hole seed-taking groove, and a groove is arranged in the seed-taking groove for soybean harvesting. The double suction hole is connected with the air suction channel, and the air suction channel is connected with the double suction hole and the negative pressure chamber. The negative pressure chamber is formed by the cooperation of the disc body and the gas cover. There is an isosceles cone ring on the body; the air cover fits on the bearing, and the ring fastens the air cover on the bearing; The isosceles cone ring clearance fit of the disc body and the gas cover is ensured. The invention realizes the universal seeding of soybeans and corns, and it is known from aerodynamics that the clearance fit between the waist surface of the isosceles cone ring will form a continuous curved path, which will have a throttling effect on the air flow, thereby reducing the air-suction discharge rate. The air pressure loss of the seeder.

Owner:JILIN UNIV

A negative pressure compact siro spinning machine

The invention provides a negative pressure compact siro spinning machine, which belongs to the technical field of textiles. It solves the problem that the existing negative-pressure compact siro spinning machine is very inconvenient to clean the hairiness and broken ends in the waste cotton collection box. When cleaning, all must be shut down and the fan stops, so the entire production line cannot continue to work. problems leading to reduced productivity. The negative pressure compact siro spinning machine includes a frame, and the frame is provided with a front roller device, a middle roller device, a rear roller device, a yarn guide hook, a special-shaped tube device and an air suction device, and the air suction device includes a The suction branch pipe connected with the negative pressure collecting pipe of the special-shaped pipe device, the cotton suction pipe with the port facing the surface of the front roller assembly, the negative pressure air collection pipe connected with the suction branch pipe, and the cotton suction air collection pipe connected with the cotton suction pipe Pipes, fan boxes. Negative pressure fan, centrifugal fan, and cotton cleaning air pump do not interfere with each other. Operators can clean the hairiness stored in the waste cotton collection box at any time without affecting the normal operation of the spinning machine.

Owner:HAINING FULIDA TEXTILE

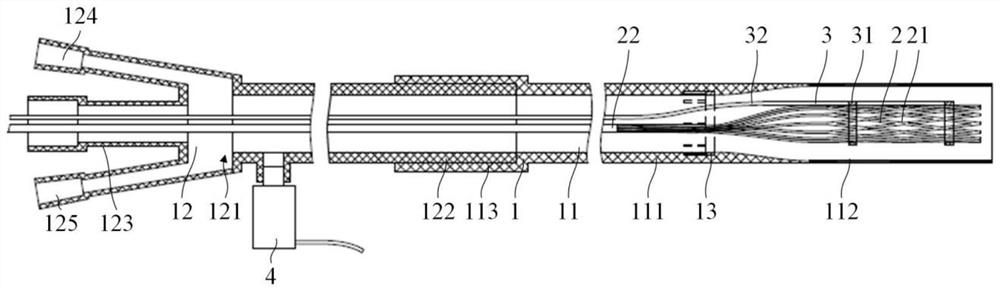

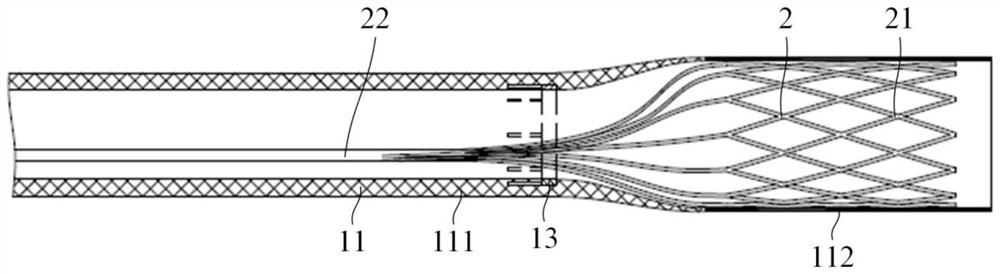

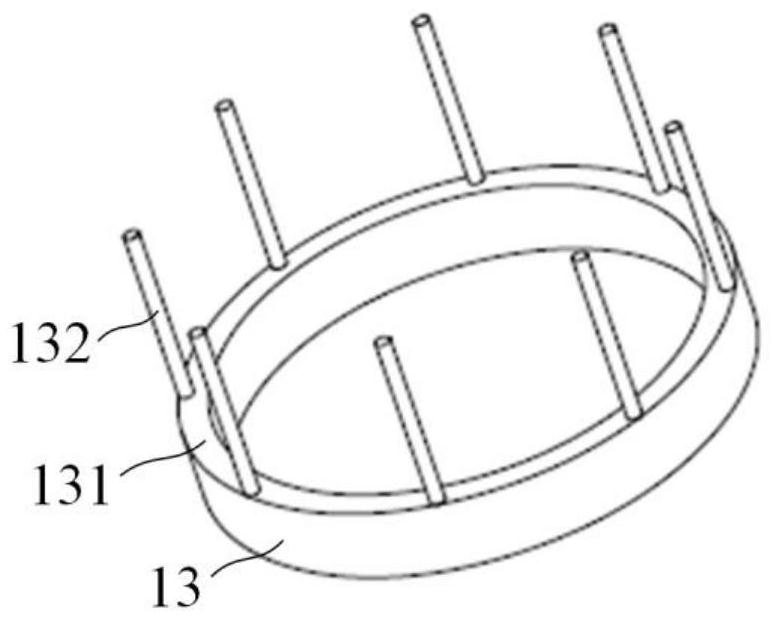

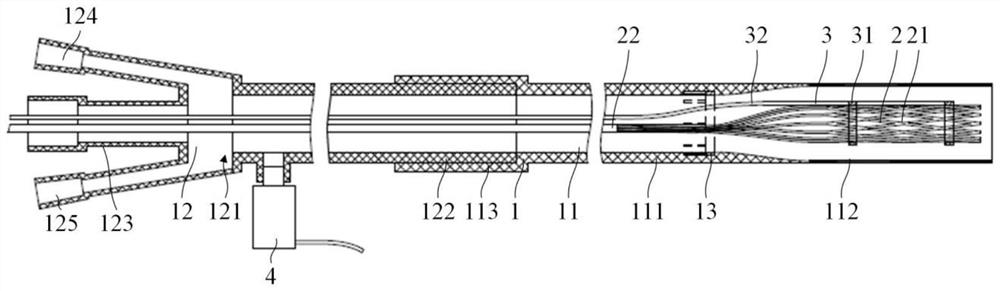

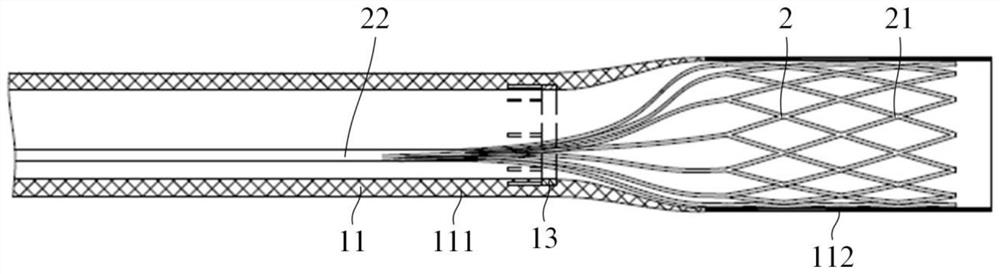

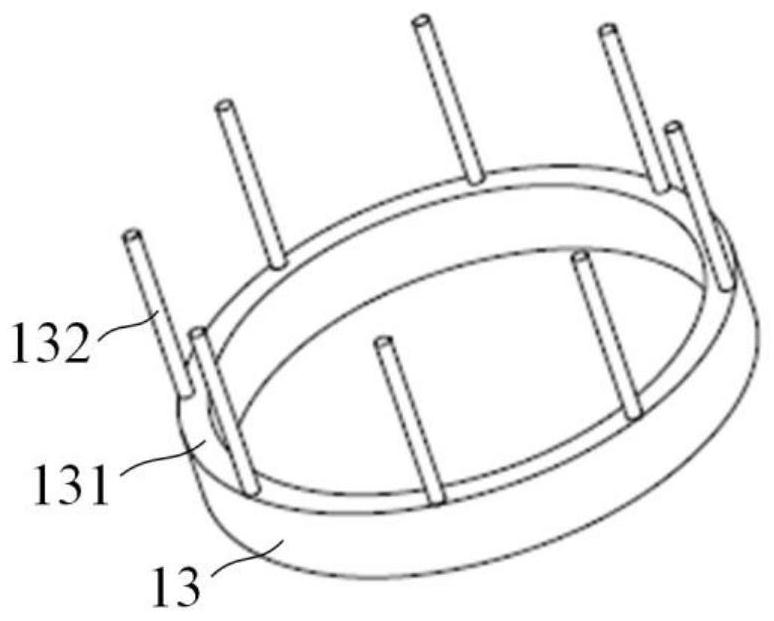

Suction catheter

ActiveCN112603461AReduce negative pressure lossIncrease lumen diameterSurgerySuction devicesThrombus aspirationGuide wires

The invention relates to the technical field of thrombus aspiration, and provides a suction catheter. The suction catheter comprises a catheter body and a supporting frame. The one end of the catheter is provided with an elastic pipe section, and the other end of the catheter is provided with a main pipe joint and a first joint, the support frame comprises a first traction guide wire and an elastic frame; the elastic frame is arranged in the catheter body in a sliding mode after being compressed, and the elastic frame can provide elastic force to enlarge the diameter of the elastic pipe section; one end of the first traction guide wire is connected with the elastic frame, and the other end extends out of the main pipe joint; and the elastic frame can slide by pushing the first traction guide wire. When the suction catheter is used, the diameter of the elastic tube section is increased through the elastic frame, the outer wall of the elastic tube section and the inner wall of a blood vessel are attached to the diameter of an inner cavity of the elastic tube section under the constraint of the inner wall of the blood vessel, and the diameter of the inner cavity of the elastic tube section is increased at the same time. Therefore, the suction catheter can aspirate thrombus from blood vessels of different sizes.

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

a suction catheter

ActiveCN112603461BReduce negative pressure lossIncrease lumen diameterSurgerySuction devicesThrombus aspirationGuide wires

The present invention relates to the technical field of thrombus suction, and provides a suction catheter. The suction catheter of the present invention includes a catheter and a support frame. One end of the conduit is provided with an elastic pipe section, and the other end of the conduit is provided with a main pipe joint and a first joint communicating with the inner cavity of the conduit. The support frame includes a first pulling guide wire and an elastic frame; the elastic frame is slidably arranged in the catheter after being compressed, and the elastic frame can provide elastic force to expand the diameter of the elastic tube section; one end of the first pulling wire is connected with the elastic frame, and the first pulling wire is connected to the elastic frame. The other end of the guide wire extends out of the main pipe joint; pushing the first pulling guide wire can make the elastic frame slide. When the suction catheter of the present invention is used, the elastic frame expands the diameter of the elastic tube section, and under the constraint of the inner wall of the blood vessel, the outer wall of the elastic tube section and the inner wall of the blood vessel fit the inner lumen diameter of the elastic tube section, and the inner lumen diameter of the elastic tube section is also increase at the same time. This enables the aspiration catheter to aspirate thrombi from vessels of different sizes.

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

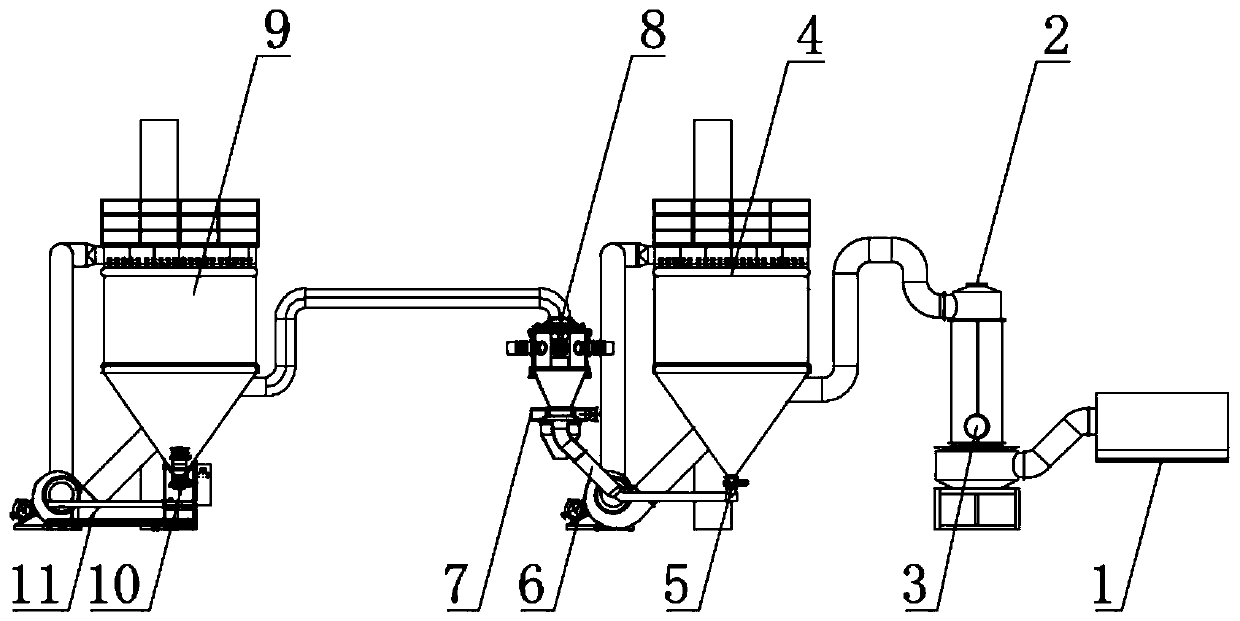

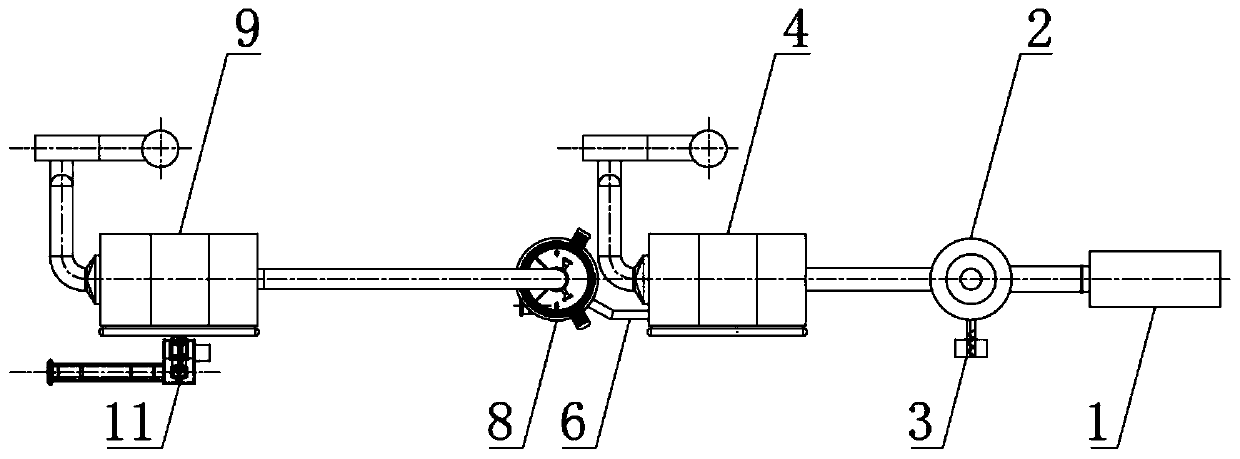

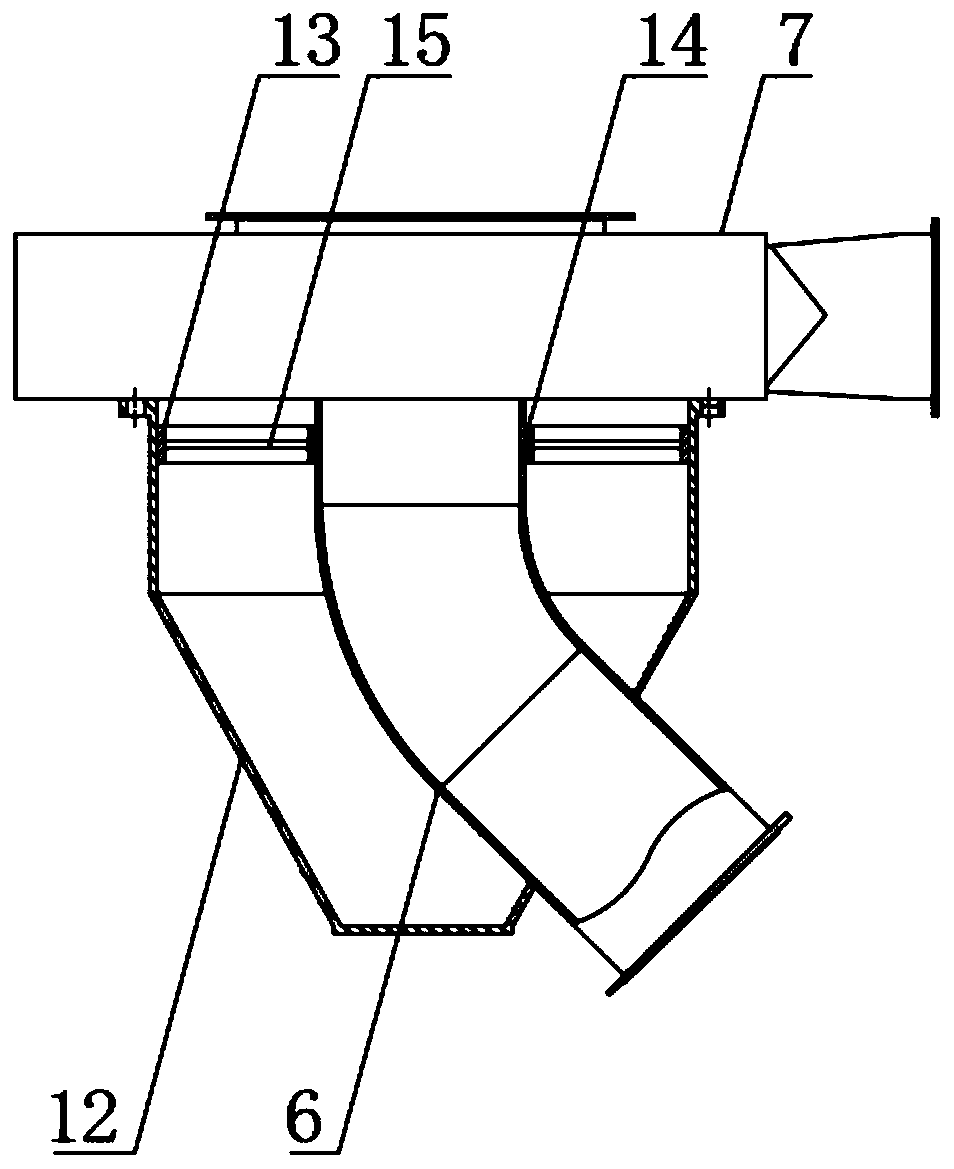

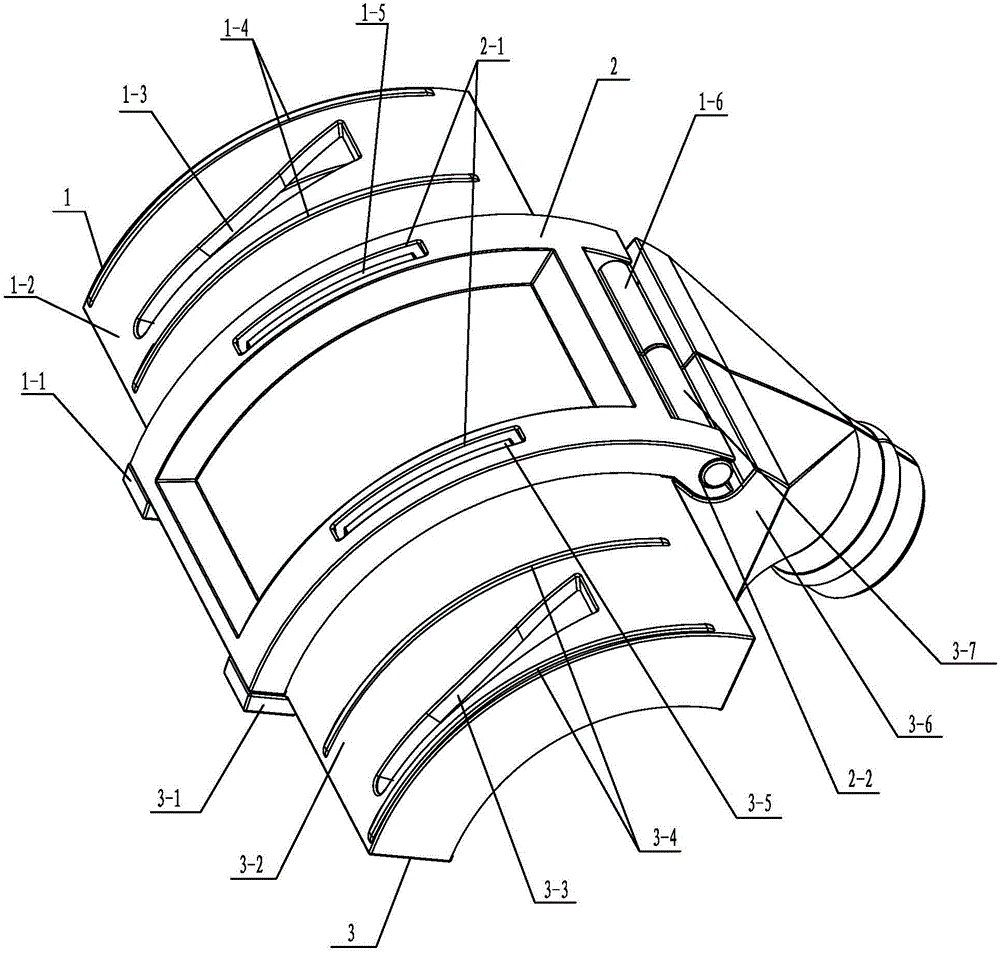

Novel chemical powder drying, sorting and packaging production line

InactiveCN110076088AReduce labor intensityNovel processGas current separationDrying solid materials with heatProduction lineCompound (substance)

The invention relates to the technical field of powder production equipment, in particular to a novel chemical powder drying, sorting and packaging production line. The production line comprises a hotblast stove; the hot blast stove is connected with a dryer through a pipe; a feeding inlet of the dryer is provided with a twin-screw feeder; the dryer is connected with a first-stage dust collectorthrough a pipe; the first-stage dust collector is provided with a first-stage feeder; the first-stage feeder communicates with a negative pressure pipeline; the negative pressure pipeline is connectedwith a centrifugal fan through a flange; the centrifugal fan is in flanged joint with a sorting machine; the sorting machine is connected with a second-stage dust collector; a discharge port of the second-stage dust collector is provided with a second-stage feeder; and an automatic weighing packaging machine is arranged under the second-stage feeder. The production line has the beneficial effectsthat the process is novel, the particle size of sorted products ranges from 3 microns to 10 microns, the water content of powder is 0.02% to 0.38%, the sorting efficiency is 97.2%, the product quality is high, full sealed operation is conducted under negative pressure, dust on site is avoided, noise is low, unorganized dust is reduced, the working environment is improved, the product packaging speed is high, and the labor intensity is relieved.

Owner:山东岳龙环保设备有限公司

Combospin Negative Pressure Air Concentration Mechanism

Owner:常州市同和纺织机械制造有限公司

Balling-resisting quick change rotary suction nozzle device

ActiveCN102631815APrevent knottingExtended service lifeDispersed particle filtrationEngineeringFilter material

The invention relates to a balling-resisting quick change rotary suction nozzle device, belonging to the technical field of spinning machines. The balling-resisting quick change rotary suction nozzle device comprises a horizontally arranged main shaft (1), wherein a suction arm (2) is inserted into the end part of the main shaft (1) and comprises a horizontal section (2.1) and an inclined section (2.2), the end part of the inclined section (2.2) of the suction arm (2) is connected with a suction nozzle (5), and a suction nozzle end surface of the suction nozzle (5) is parallel to the central line of the main shaft (1). According to the balling-resisting quick change rotary suction nozzle device disclosed by the invention, the suction nozzle and the suction arm are of quick connection structures and are very convenient to replace, and the lengths of the suction nozzle and the suction arm can be configured as required; a rubber suction nozzle is sleeved on the suction nozzle so that the suction nozzle does not generate static electricity with a filtering material so as to be capable of effectively preventing the filtering material from balling and hardening and prolonging the service life of the filtering material. The horizontal section and the inclined section of the suction arm are bent into 120 degrees, a diameter range is set, the area of a suction nozzle is large, and the loss of negative pressure is less.

Owner:JIANGSU JINGYA ENVIRONMENT TECH

Double-side technological cotton suction device of ring spinning frame

PendingCN107604491AGuarantee the negative pressure requirements of broken end suction cottonTotal airflow reductionTextiles and paperYarnEngineering

The invention relates to a double-side technological cotton suction device of a ring spinning frame. The double-side technological cotton suction device comprises a tail cotton suction air box, a tailair pipe, a tail cotton suction fan, a head cotton suction air box, a head air pipe, a head cotton suction fan, a first middle air pipe and a second middle air pipe. The head cotton suction air box is connected with the first middle air pipe by the head air pipe, the tail cotton suction air box is connected with the second middle air pipe by the tail air pipe, the first middle air pipe and the second middle air pipe are connected with each other and are closed, and the head cotton suction fan and the tail cotton suction fan are arranged in the head cotton suction air box and the tail cotton suction air box. The double-side technological cotton suction device has the advantages that one-way technological cotton suction of a long vehicle is transformed into technological cotton suction of two short vehicles, the original long air pipes are changed into the two short air pipes under the condition that the cross sections of the middle air pipes are guaranteed against being changed, the air pipes are shortened, the total quantity of airflow in the air pipes can be reduced, the flow rate can be lowered, negative pressure loss can be reduced, the consistency of the internal negative pressures of the air pipes can be enhanced, the negative pressure balance can be effectively improved, and cotton suction negative pressure requirements of broken ends of yarns can be assuredly met.

Owner:JINGWEI TEXTILE MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com