Method for cutting a string-shaped food and cutting machine

A cutting machine, food technology, applied in metal processing, workpiece clamping devices, manufacturing tools, etc., can solve problems such as adverse effects, faulty cutting quality, etc., and achieve the effect of maintaining integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

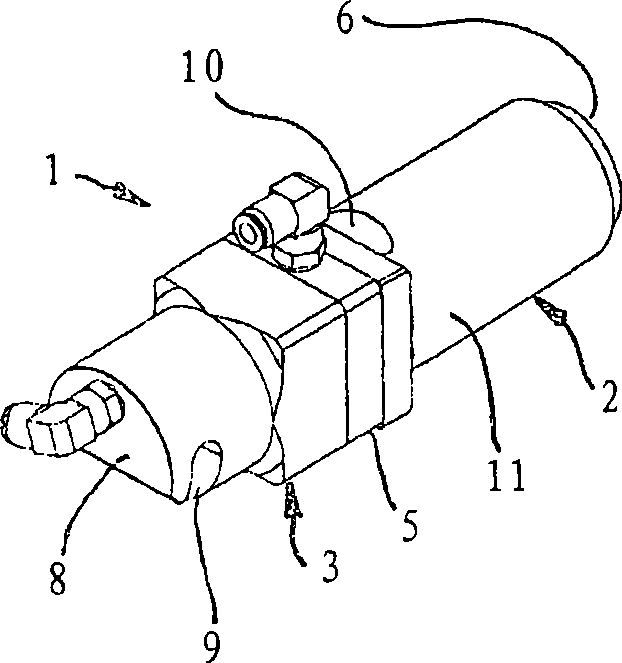

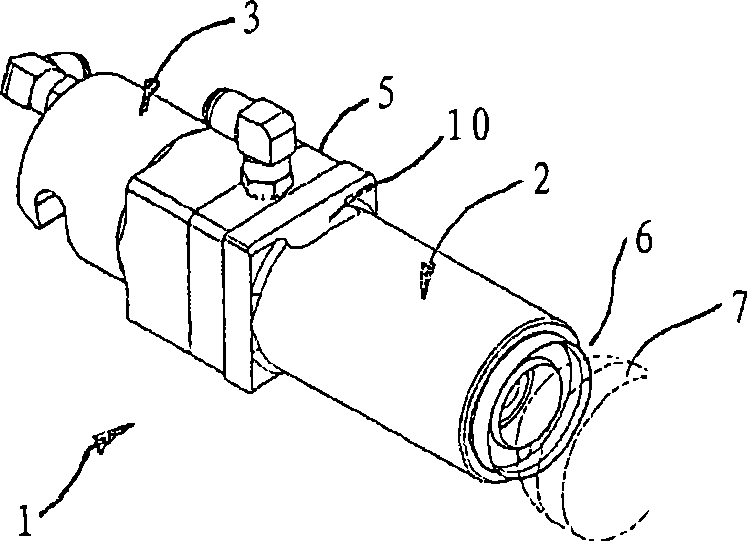

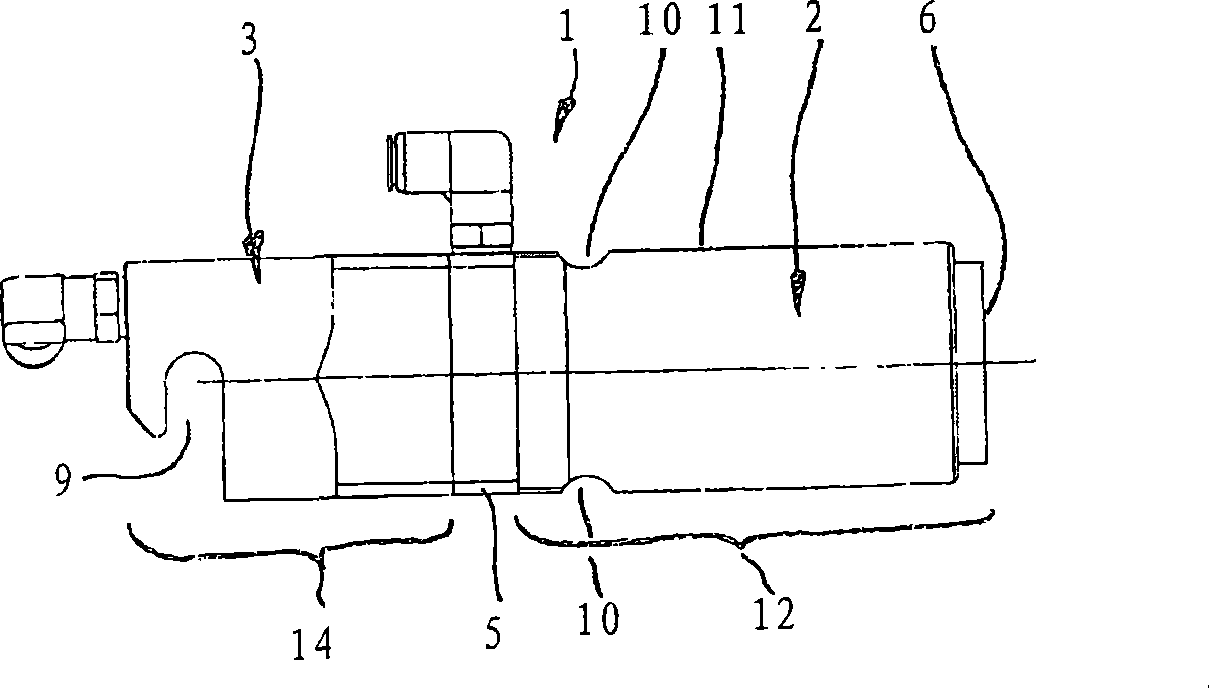

[0031] Figure 1 to Figure 5b The vacuum gripper 1 shown in is composed of two coaxially arranged piston-cylinder units 2 and 3, which are connected to each other by a common piston rod 4 and separated from each other by a partition 5, which slides and seals It is supported in the partition 5.

[0032] The vacuum gripper 1 has a front side 6 on which a figure 1 A strip 7 in the form of a sausage, for example, is indicated by a dotted line. The vacuum gripper 1 has a rear side 8 opposite (to the front side 6 ), on which the vacuum gripper can be fastened by means of a groove-shaped recess 9 Figure 6 to Figure 8 On the underframe of the grabbing device shown, the grabbing device will be described in detail later. In addition, the two groove-shaped recesses 10 in the outer surface 11 of the vacuum gripper 1 also serve for the described fastening.

[0033] The vacuum gripper 1 has a front part 12 connected to the partition 5 and formed by the piston-cylinder unit 2 , which is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com