Balling-resisting quick change rotary suction nozzle device

An anti-caking and suction port technology is applied in the separation of dispersed particles, chemical instruments and methods, and the filtration of dispersed particles. Small pressure loss and large suction port area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

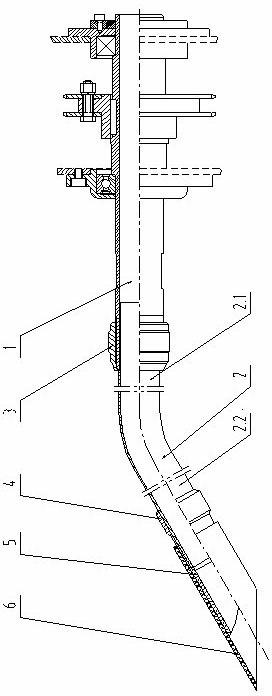

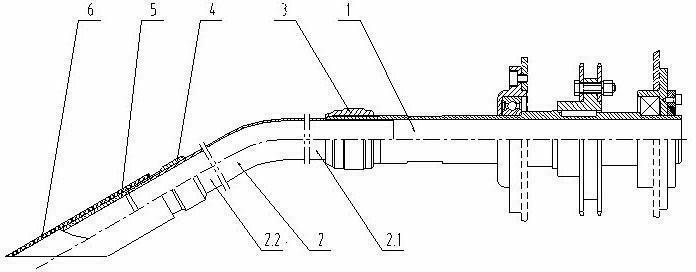

[0017] see figure 1 , the present invention relates to an anti-balling quick-change rotary suction nozzle device, which includes a horizontally arranged main shaft 1, a suction arm 2 is inserted into the end of the main shaft 1, and a lock is passed between the main shaft 1 and the suction arm 2. The tight nut I3 is fixed, the suction arm 2 includes a horizontal section 2.1 and an inclined section 2.2, the angle between the horizontal section 2.1 and the inclined section 2.2 of the suction arm 2 is 120°, and the inclined section 2.2 of the suction arm 2 The end is connected with a suction nozzle 5, the suction end surface of the suction nozzle 5 is parallel to the center line of the main shaft 1, the suction nozzle 5 and the suction arm 2 are connected by threads and fixed by a lock nut II4, the The suction nozzle 5 is covered with a rubber suction nozzle 6 .

[0018] The rubber suction nozzle 6 can also be replaced with other materials such as plastic suction nozzles that do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com