Cotton suction branch pipe of spinning frame

A spinning frame and branch pipe technology, applied in textiles and papermaking, etc., can solve the problems of affecting the air conveying efficiency, large negative pressure loss, irregular air turbulence, etc., to improve the connection method, reduce negative pressure loss, and eliminate airflow disturbance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

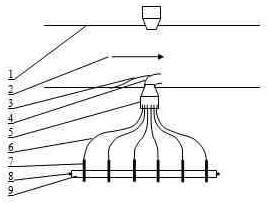

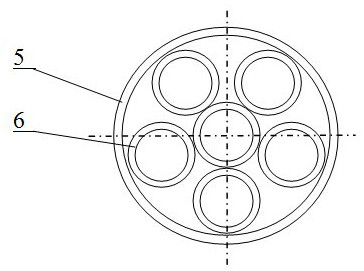

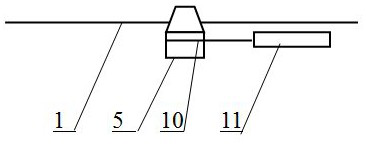

[0019] Refer to attached figure 1 and figure 2 , a cotton suction branch pipe of spinning frame, including branch pipe connection distributor 5 connected with main suction duct 1, branch pipe 6, branch nozzle 7 and branch pipe support rod 9. The interface with the main suction duct 1 and the branch pipe is a branch pipe connecting distributor 5 for multiple spindle positions. One end of the branch pipe 6 corresponding to each spindle position is inserted into the connection distributor 5, and the other end is connected to the branch nozzle of the corresponding spindle position. 7. The branch nozzle 7 is detachably clamped on the branch support rod 9, and the chucks 8 at both ends of the branch support rod 9 are detachably clamped on the roller seats on both sides, and the branch nozzle 7 is located at the output of the front roller jaw.

[0020] The branch pipe connection distributor 5 is one divided into four to ten spindle positions, especially one divided into four or fiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com