Novel suction system of piggyback cotton picker

A cotton picker and knapsack-type technology, applied in the field of cotton pickers, can solve the problems of high energy consumption of the suction system, damage to cotton fibers, and low energy utilization rate, so as to achieve high energy utilization rate, reduce negative pressure loss, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

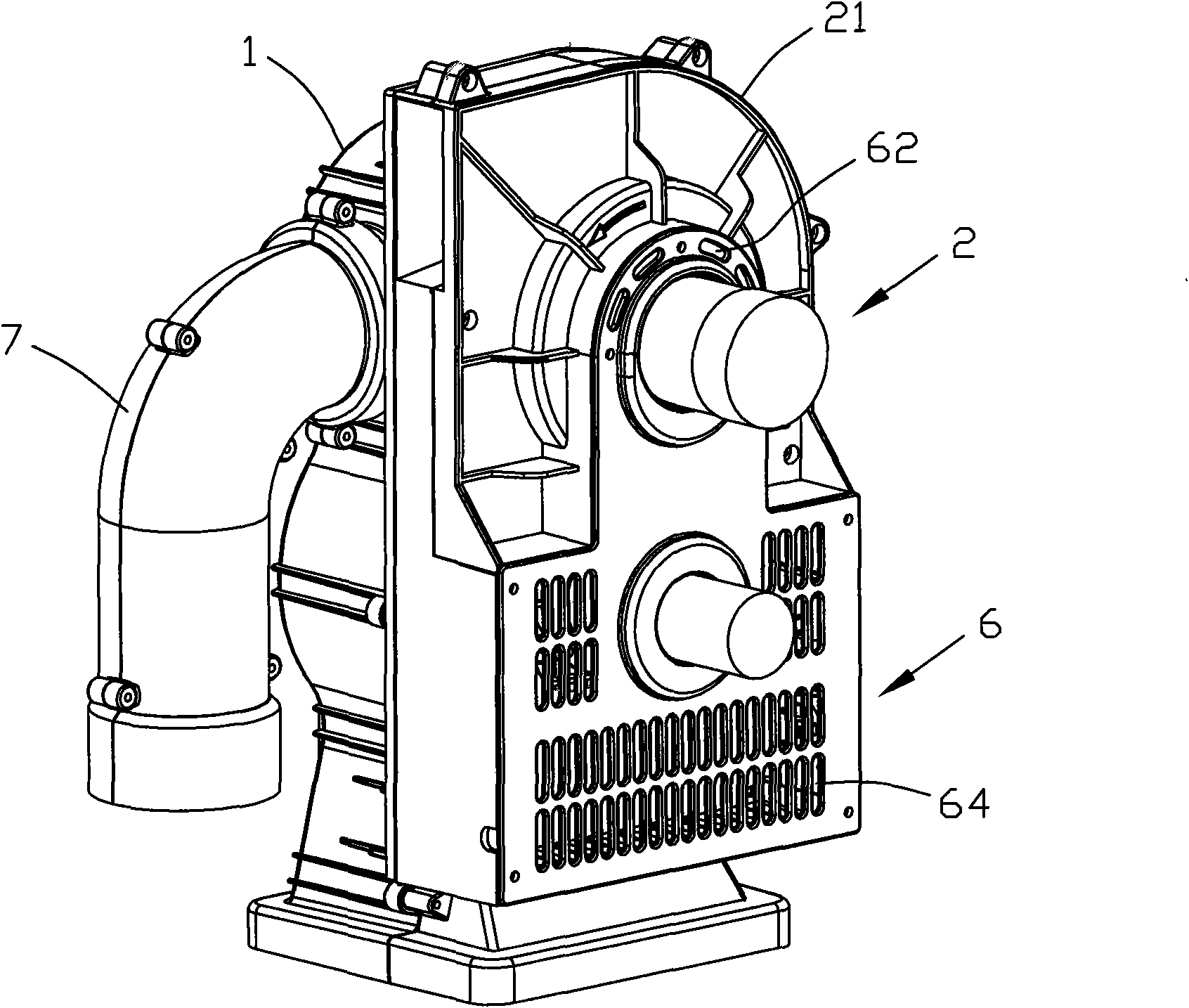

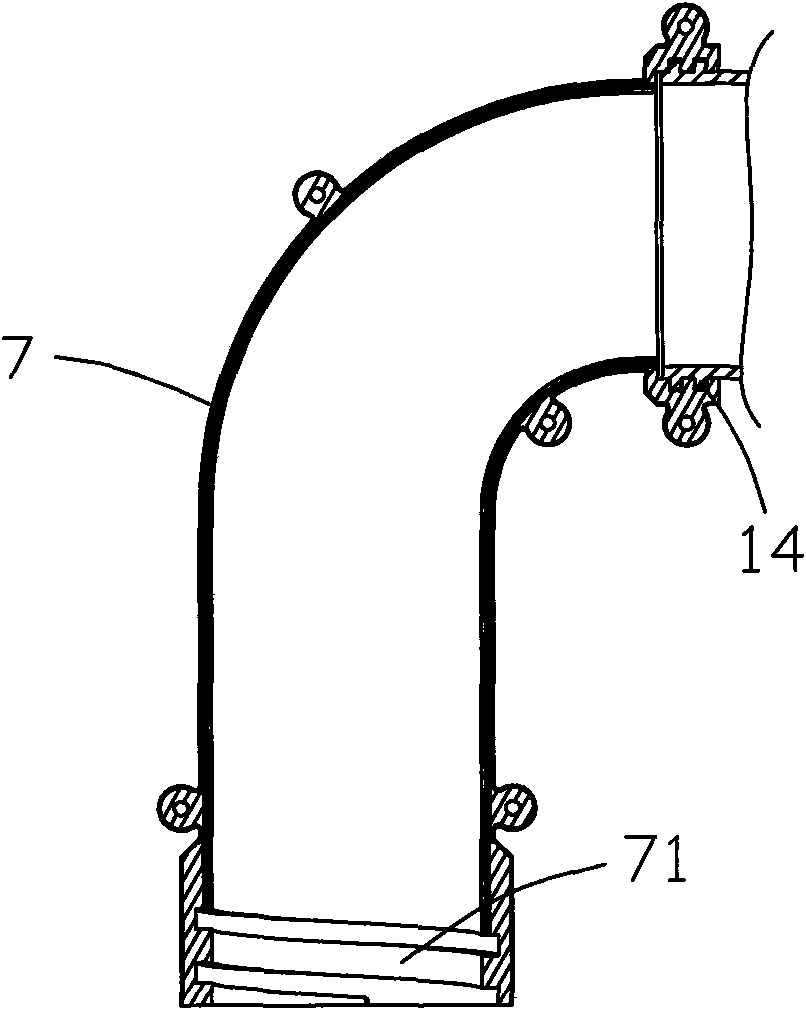

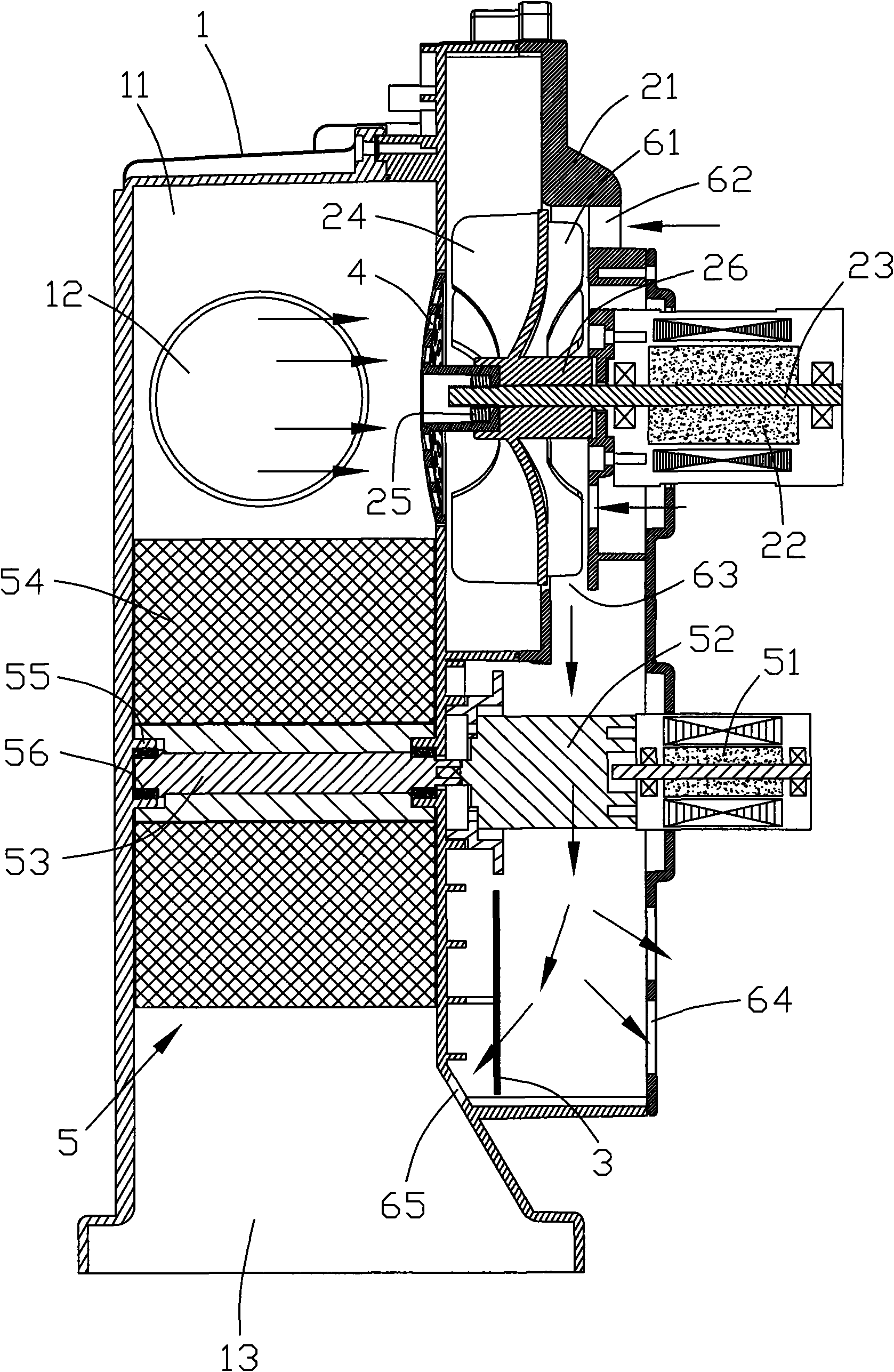

[0023] Such as Figure 1 to Figure 3 As shown, it is a novel air suction system of the knapsack cotton picker of the present invention, comprising a main housing 1, a main fan 2 and a circuit board 3 for controlling the main fan 2, the top of the main housing 1 is provided with a cotton inlet 12, and the bottom is provided with a Cotton outlet 13, cotton outlet 13 connects cotton collection bag; Main blower 2 rotates work under the control of circuit board 3, and main blower 2 comprises the main motor 22 in fan housing 21 and fan housing 21, and main motor 22 adopts direct current The brush motor, the output shaft 23 of the main motor 22 is provided with the main fan blade 24 for cotton dynamic transmission, the output shaft 23 drives the main fan blade 24 to rotate to form a negative pressure chamber 11 in the main housing 1; the inlet of the negative pressure chamber 11 That is, the cotton inlet 12 of the main housing 1 is connected to the elbow 7 for cotton inlet. The inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com