Bionic resistance-reducing noise-reducing surface of rigid and flexible structure

A resistance drop, rigid and flexible technology, applied in the direction of mechanical equipment, fluid flow, etc., can solve problems such as huge energy consumption, achieve the effects of reducing flow noise, reducing frictional resistance, and suppressing frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

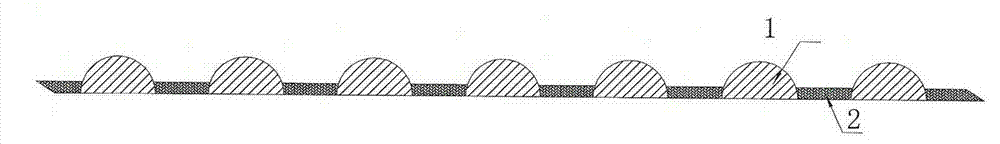

[0015] see figure 1 and Figure 4 As shown, it is the first embodiment of the present invention. This embodiment is composed of rigid ribs 1 and flexible strips 2 alternately distributed on the rigid surface. The cross-sectional shape of the rigid rib 1 is semicircular, and its radius R is 3mm. The spacing L between the rigid ribs 1 is 10mm, and the thickness N of the flexible strips 2 is 2mm.

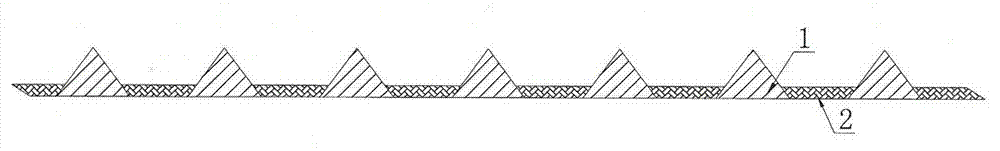

[0016] see figure 2 and Figure 5 As shown, it is the second embodiment of the present invention. This embodiment is composed of rigid ribs 1 and flexible strips 2 distributed alternately and alternately on the rigid surface. The cross-sectional shape of the rigid rib 1 is triangular, and its triangular vertex angle α is 60° , the height H from the apex to the bottom is 5mm, the distance L between the rigid ribs 1 is 8mm, and the thickness N of the flexible strip 2 is 2mm.

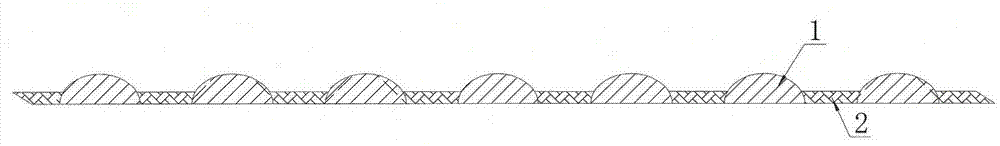

[0017] see image 3 and Image 6 Shown is the third embodiment of the present invention. This embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com