Opening-closing mechanism with self-locking devices

A technology of an opening and closing mechanism and a self-locking device, which is applied to the control mechanism, power control mechanism, locomotive and other directions of the wing fan, can solve the problems of high cost and complex structure, and achieve the effects of convenient maintenance, simple manual locking and simplified structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

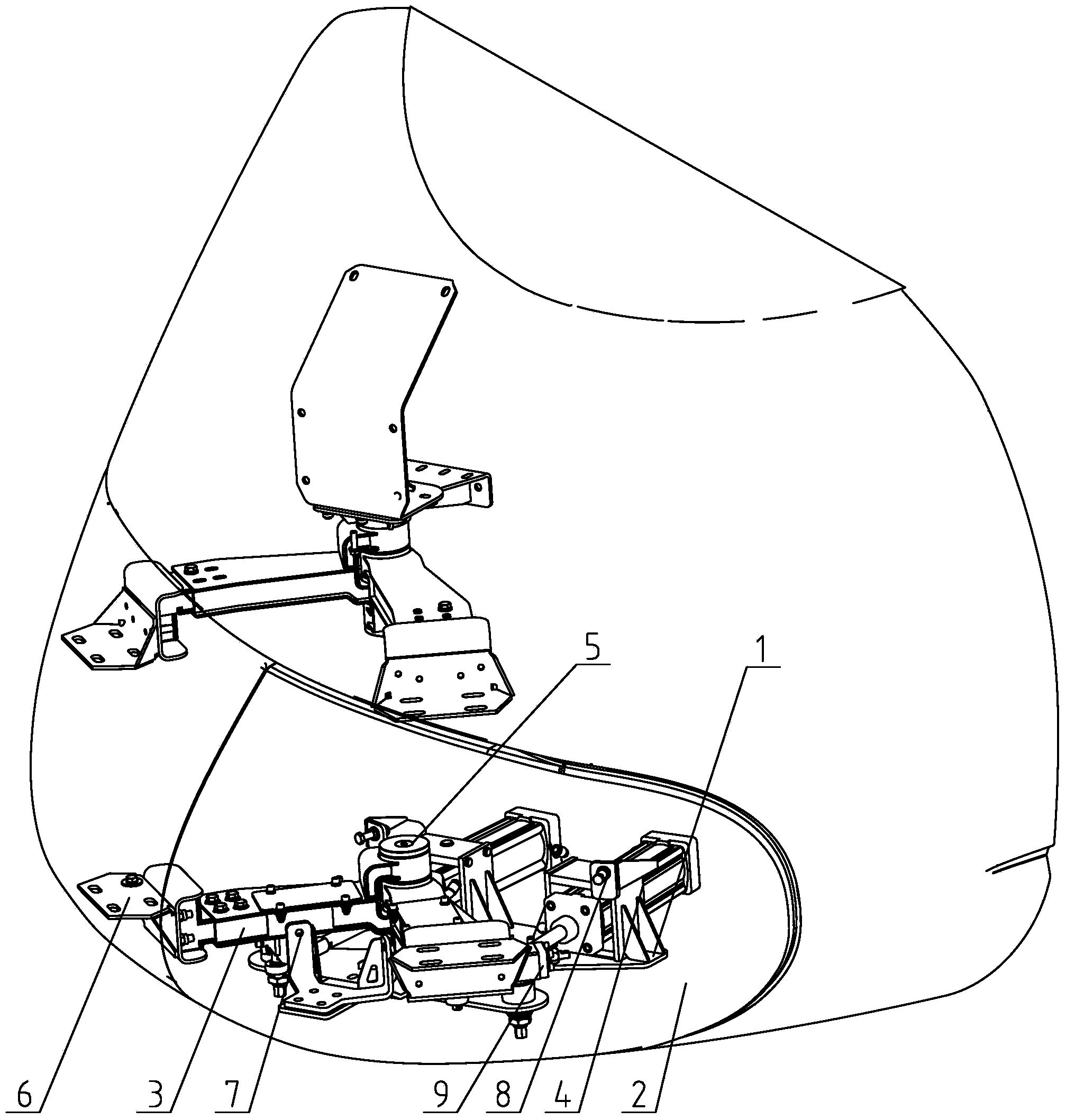

[0018] Specific embodiment one: as Figures 1 to 4 As shown, an opening and closing mechanism with a self-locking device, the opening and closing mechanism includes a bottom plate 1, a fairing 2, a fairing support arm 3 and a power source pushing cylinder 4, a rotating shaft 5 is arranged on the bottom plate 1, and the fairing supports One end of the arm 3 is set on the rotating shaft 5, and the other end is connected with the fairing 2 through the fairing mounting seat 6; An open state limit stopper 8 is arranged between them; a locking device 9 is arranged between the cowling support arm 3 and the power source pushing cylinder 4, and one end of the locking device 9 can move in the chute of the cowling support arm 3, and the other One end is installed on the power source pushing cylinder 4. During the opening or closing process of the opening and closing mechanism, the locking device 9 moves to form a mechanism dead point with the fairing support arm 3. When locking, the lock...

specific Embodiment 2

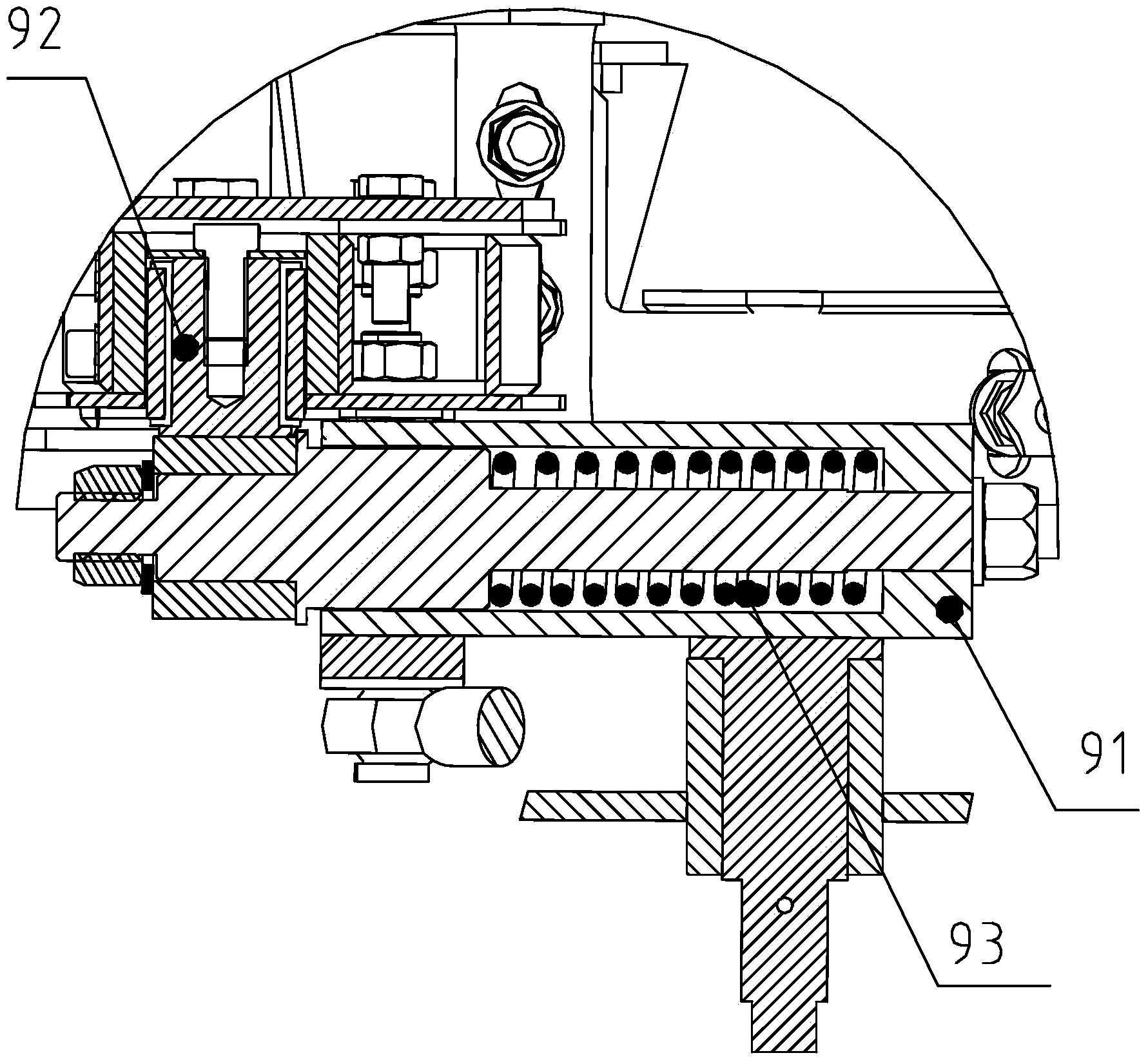

[0024] Specific embodiment two: different from specific embodiment one, in specific embodiment two, in order to realize the rolling connection between the locking device 9 and the fairing support arm 3, and play a self-locking role, the locking device 9 includes a cylinder 91 , the cylinder body 91 is preloaded with a roller device 92 and a spring 93, and one end of the cylinder body preloaded with the roller device is rollingly connected with the fairing support arm through the roller device, and the roller device can roll in the fairing support arm, and the roller of the roller device The bottom is connected with the power source push cylinder.

specific Embodiment 3

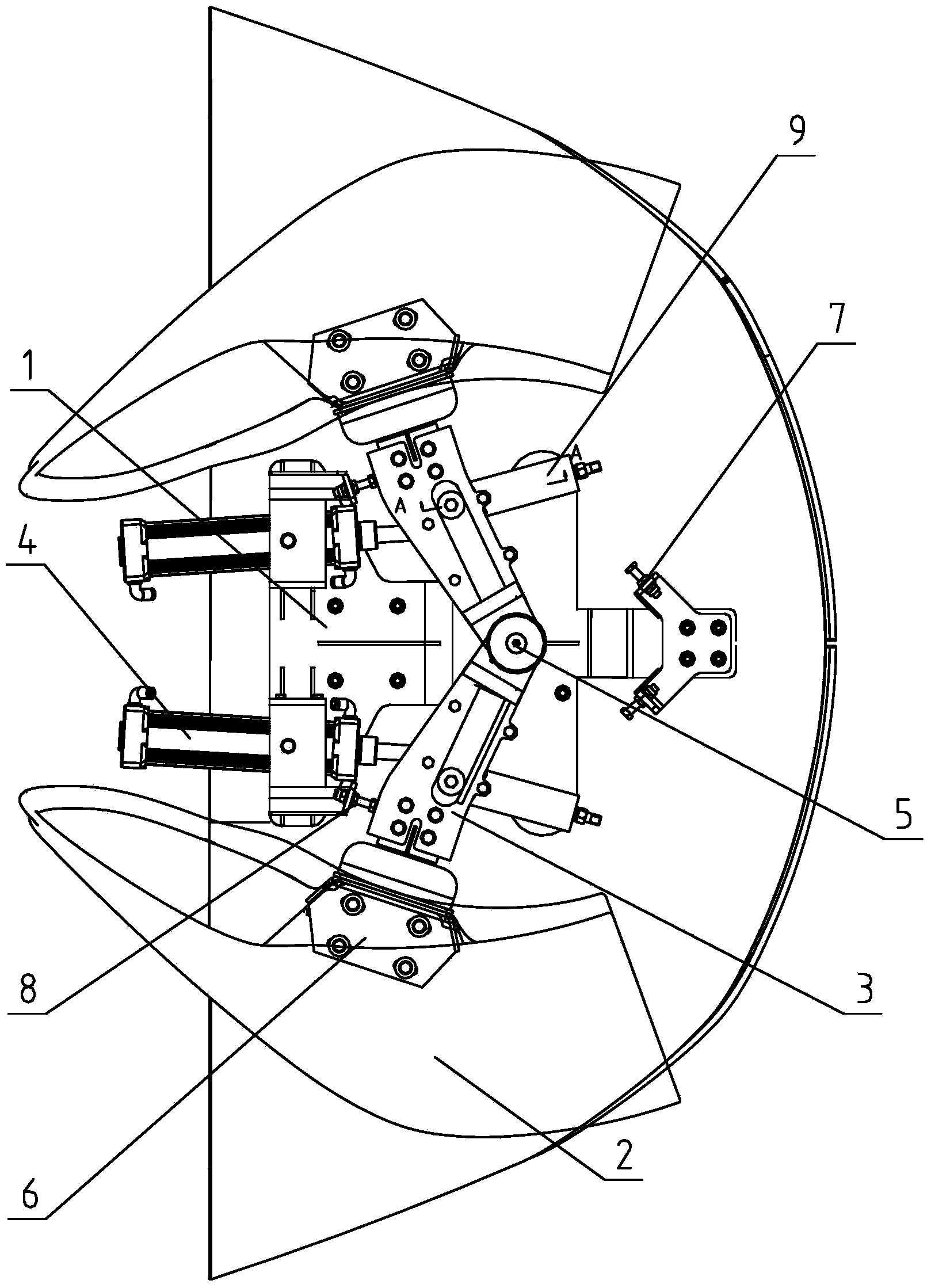

[0025] Specific embodiment 3: different from specific embodiment 1, in specific embodiment 3, there are two rotating shafts 5 located on both sides of the bottom plate 1, and the two rotating shafts 5 are respectively fitted with the fairing support arms 3 on the same side One end of the fairing support arm 3 is connected with the fairing 2 through the fairing mounting seat 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com