Direct driving type pressure expanding guide vane adjusting device

A regulating device, direct-drive technology, applied in the components of the pumping device for elastic fluids, non-variable displacement pumps, machines/engines, etc., can solve the problems of high manufacturing cost and complex structure, and reach the Low, simple structure, to ensure the effect of synchronous adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below the present invention will be further described in conjunction with accompanying drawing:

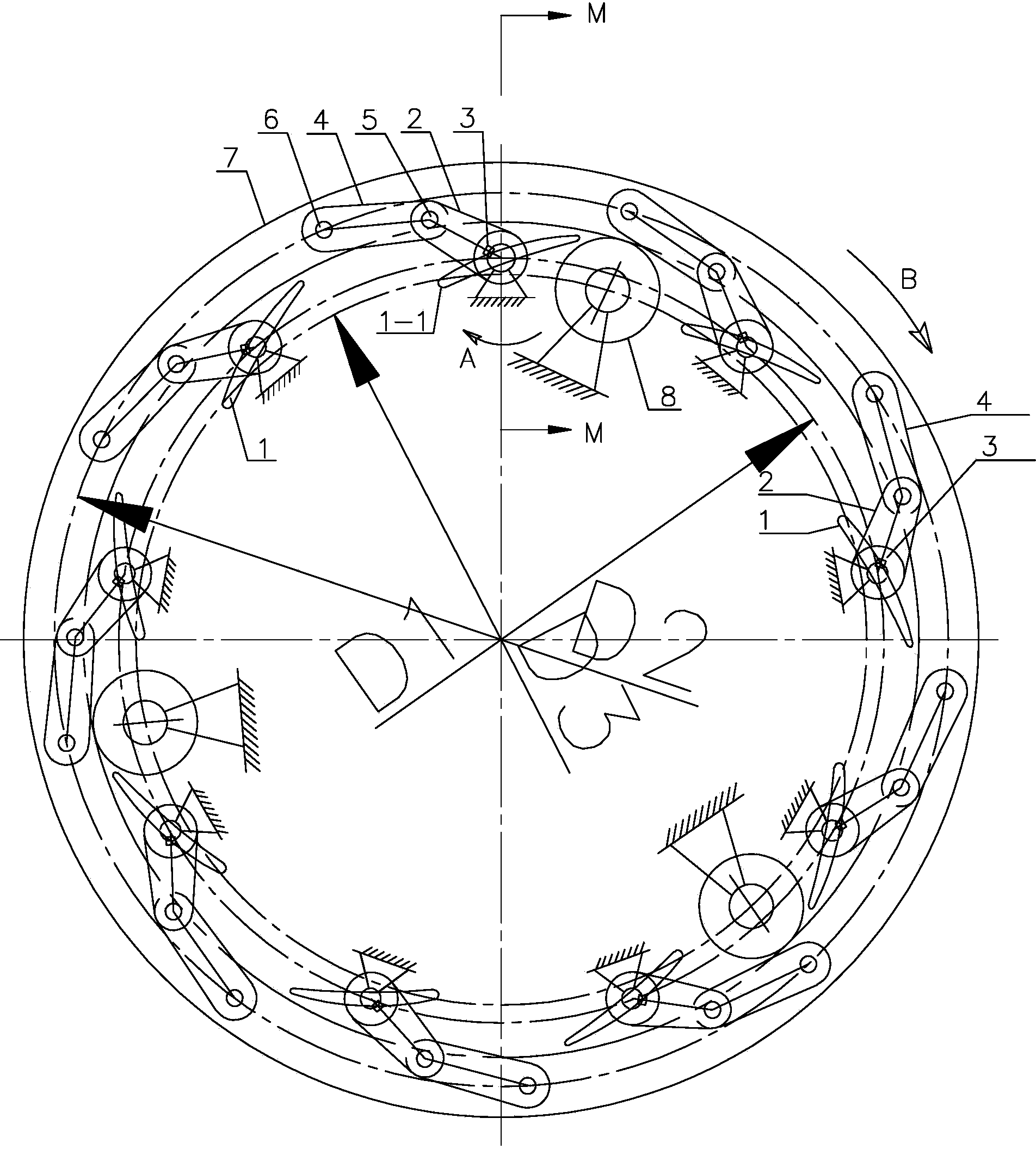

[0012] Such as figure 1 , figure 2 Shown: the present invention includes guide vane 1, rotating arm 2, first key 3, connecting rod 4, first pin shaft 5, second pin shaft 6, turntable 7, roller 8, motor 9, gearbox flange 10, etc. . There are 9 guide vanes 1 in total, and the journals of each guide vane are respectively installed in the first shaft holes evenly distributed on the gearbox flange 10 to form a first rotating pair; there is a guide vane 1 Active guide vane 1-1, the rest are driven guide vanes. Each of the rotating arms 2 is fixedly coupled with the journal of each guide vane 1 through the first key 3; one end of each connecting rod 4 is respectively connected with each rotating arm 2 through the first pin shaft 5 and forms a The second rotating pair, the other end of the connecting rod 4 is respectively connected with the evenly distributed shaft holes on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com