Fixing structure of reflector in a kind of LED backlight module

A backlight module and fixed structure technology, applied in the field of television, can solve the problems of double-sided adhesive positioning function failure and failure, and achieve good luminous efficiency, firm and reliable positioning, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

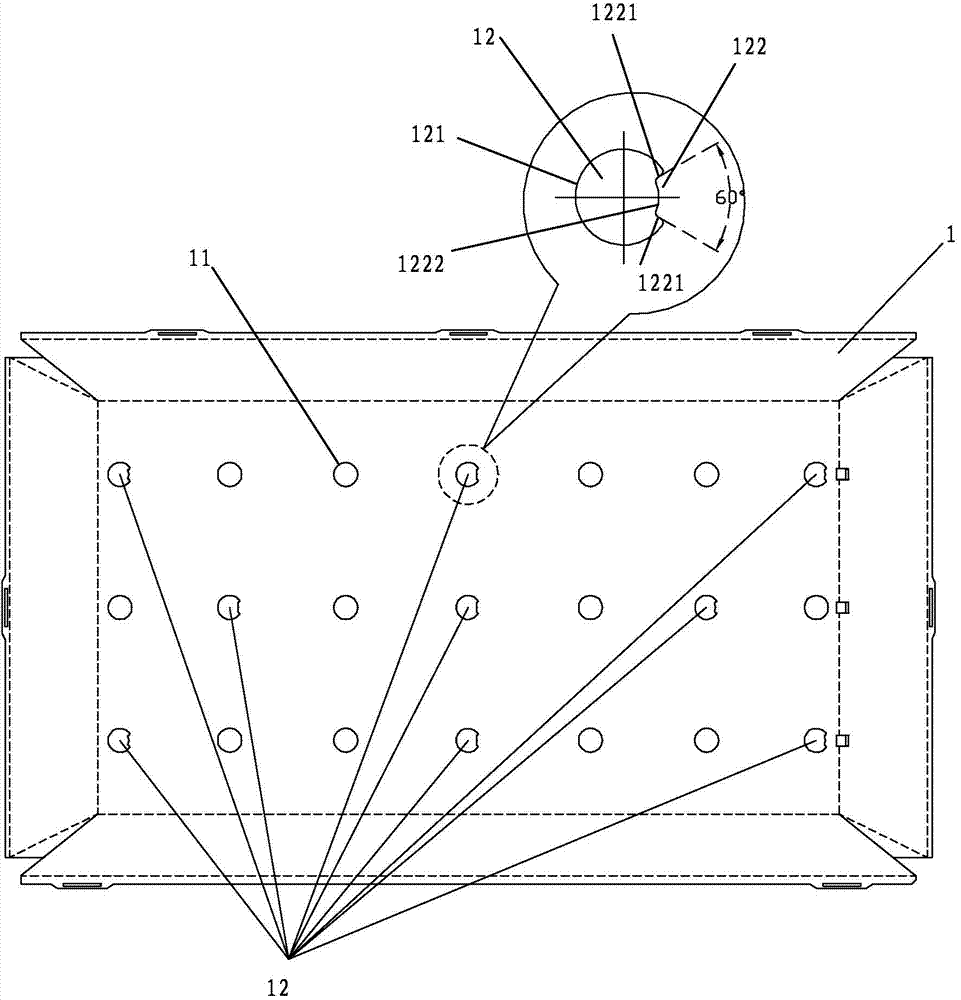

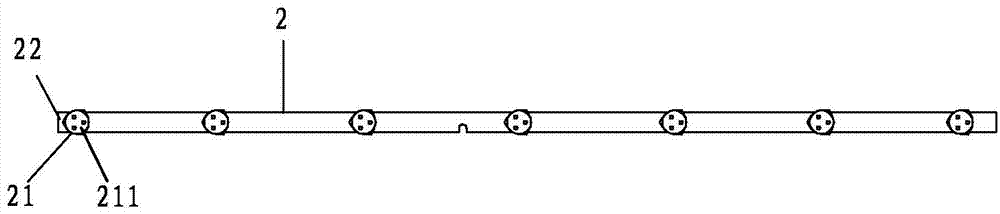

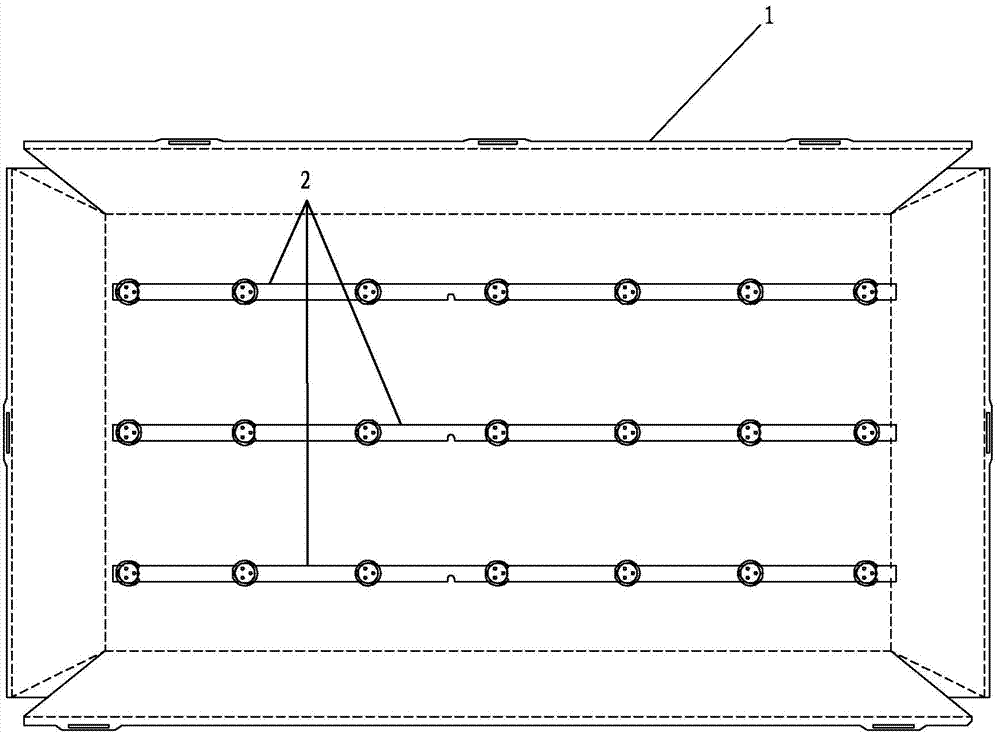

[0024] Such as Figure 1 to Figure 5 As shown, the present invention provides a fixing structure for the reflector in the LED backlight module, including the reflector 1 and the LED lamp assembly; in this embodiment, several such as figure 2 The single LED light strips 2 shown are arranged in parallel with each other at intervals to form an LED light assembly; in the backlight module of this embodiment, each LED light strip 2 is fixed on the hardware backplane 3, as shown in Figure 4 and Figure 5 shown;

[0025] The LED light bar 2 includes a light bar PCB board 22 and several LED lamps 21 connected on the light bar PCB board 22, such as figure 2 As shown, therefore, a plurality of LED lamps 21 arranged at intervals are formed on the LED lamp assembly composed of several single LED lamp bars 2 arranged in parallel and at intervals, as shown in image 3 As shown; there is a first gap 23 between the lampshade 211 of each LED lamp 21 and the light bar PCB board 22 (as Fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap