Disk brake device

A disc brake and braking surface technology, applied in the direction of brake transmission, brake, brake type, etc., can solve the problems of complicated device structure and achieve the effect of sufficient braking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

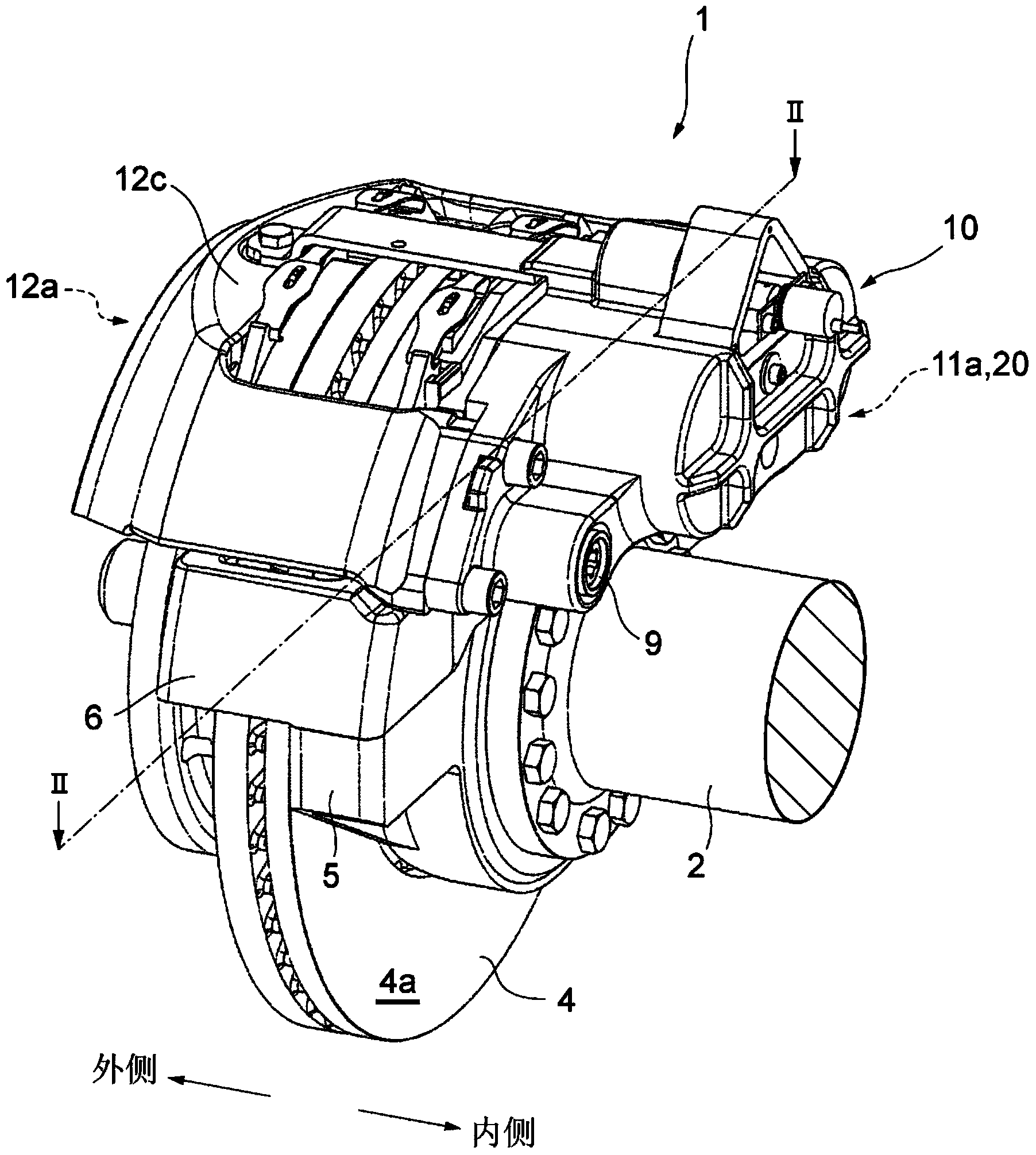

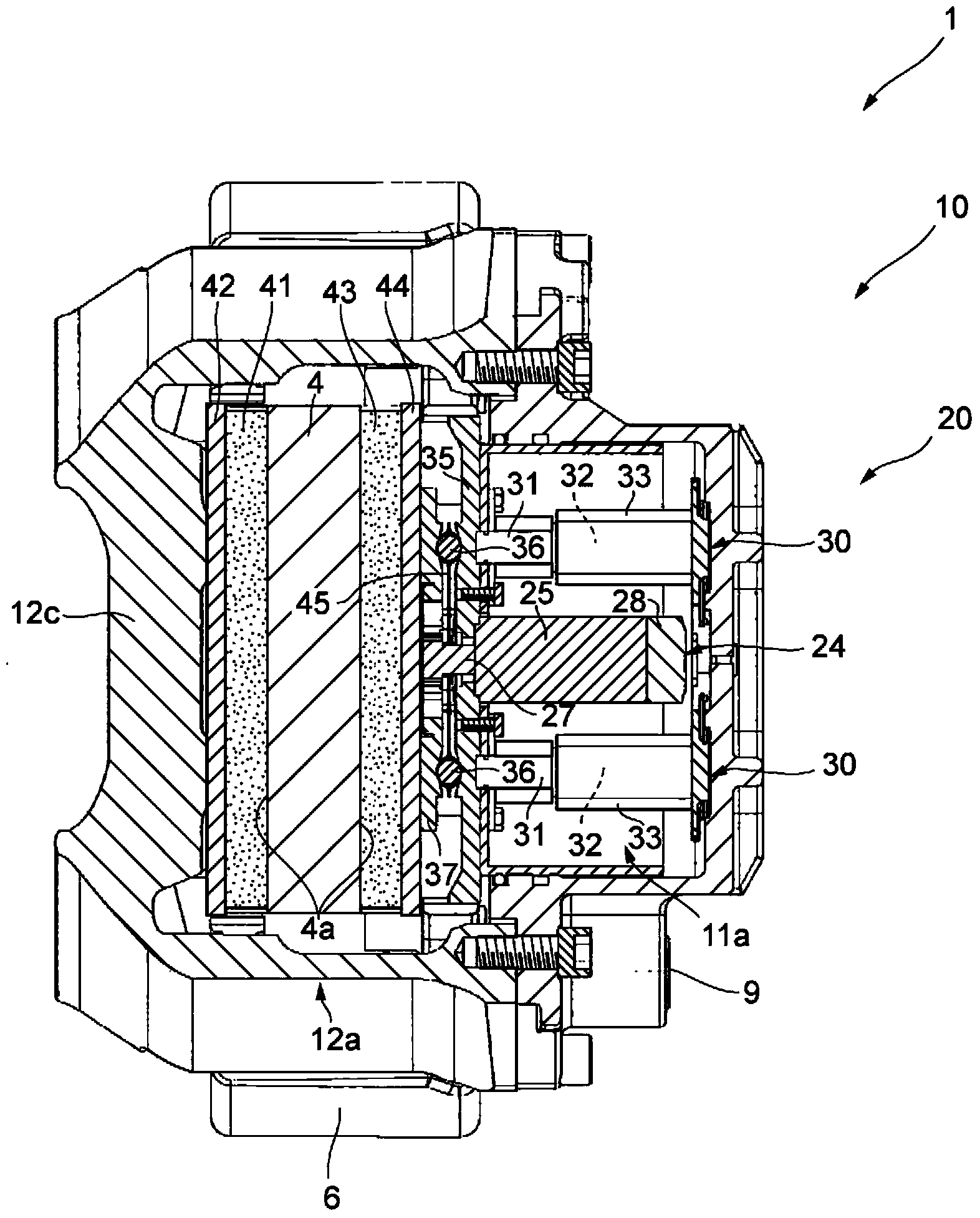

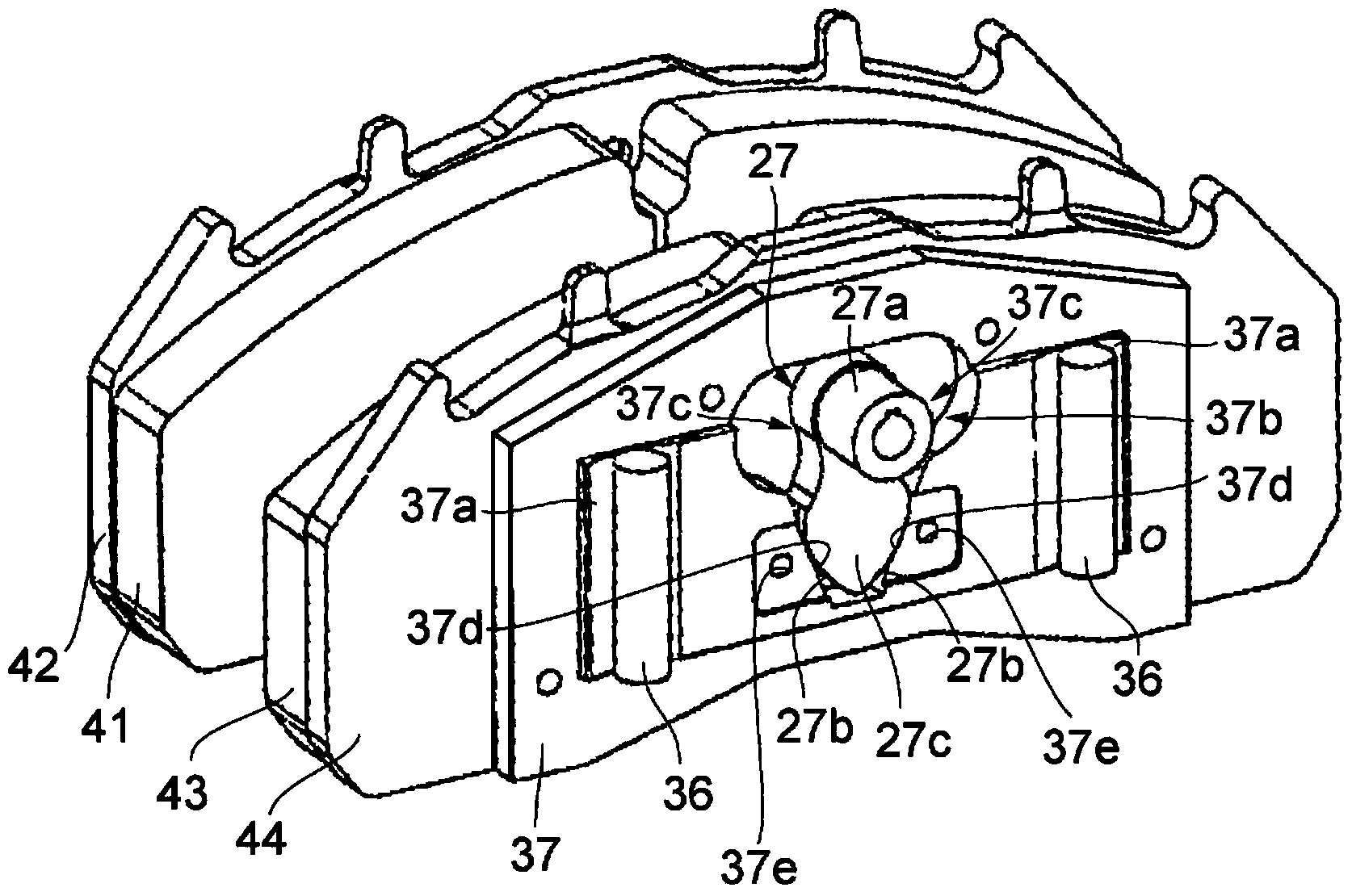

[0033] A description will be given below of an embodiment for carrying out the invention with reference to the drawings. figure 1 A perspective view of a disc brake device 1 as an example to which the present invention is applied is shown. First, refer to Figure 1 to Figure 7 A description is given of the overall configuration of the disc brake device 1 . Note that in the description given below, the outer side in the left-right direction of the vehicle is referred to as the outer side, and conversely, the inner side in the left-right direction of the vehicle is referred to as the inner side.

[0034] Such as figure 1 and figure 2 As shown, in the disc brake device 1, the caliper assembly 10 configured by accommodating the inner unit 20 in the inner space 11a on the inner side and housing the inner pad 43 and the outer pad 41 in the opening 12a on the outer side is arranged in Both sides of the caliper assembly 10 hold the ends of the rotor 4 formed into a disk shape. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com