Drying device used for spinning

A drying device and box technology, applied in drying, drying machine, drying solid materials and other directions, can solve the problems of increasing production cost, uneven drying, large energy consumption, etc., and reduce heat dissipation. , reduce production costs, the effect of high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

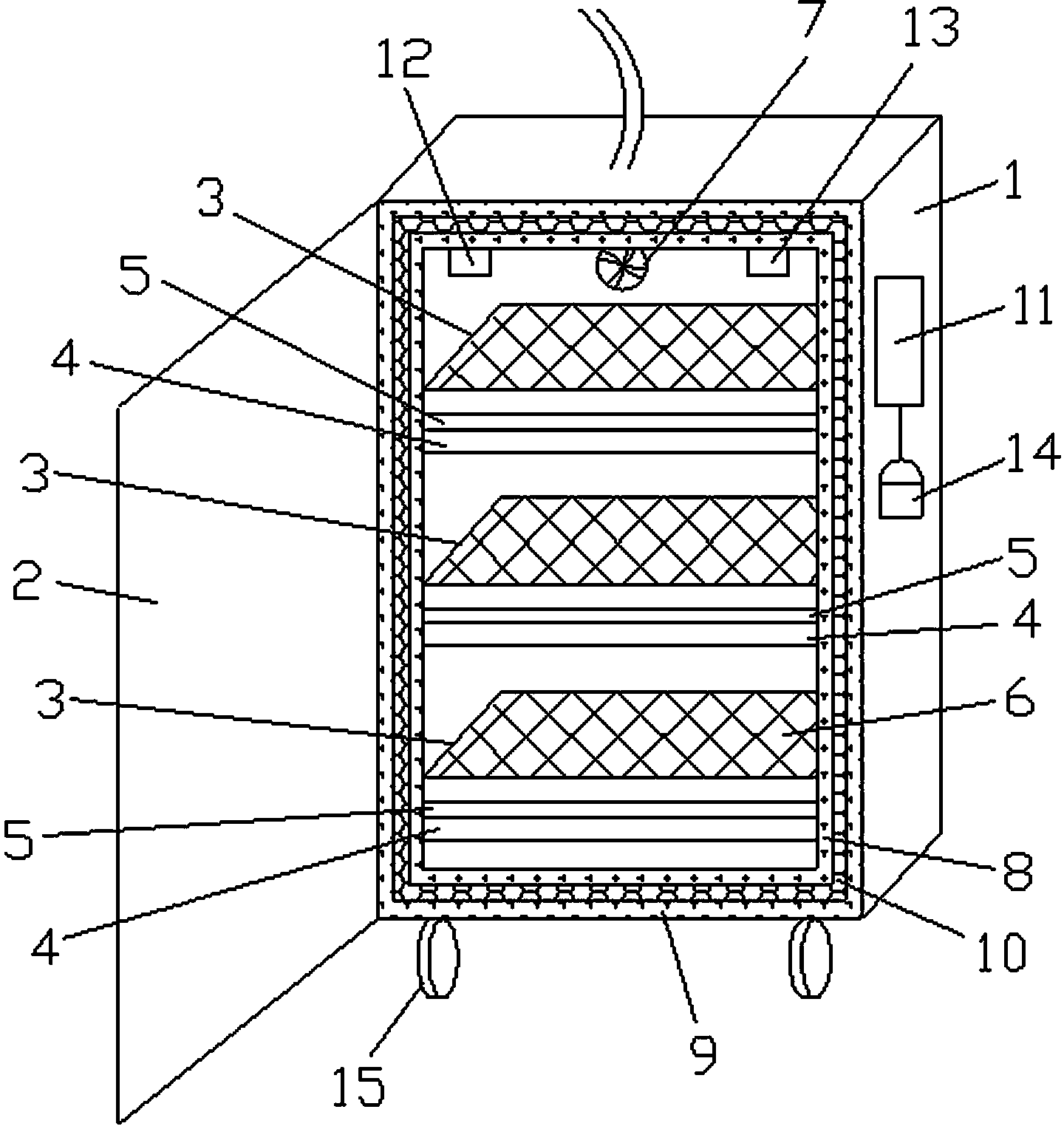

[0016] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

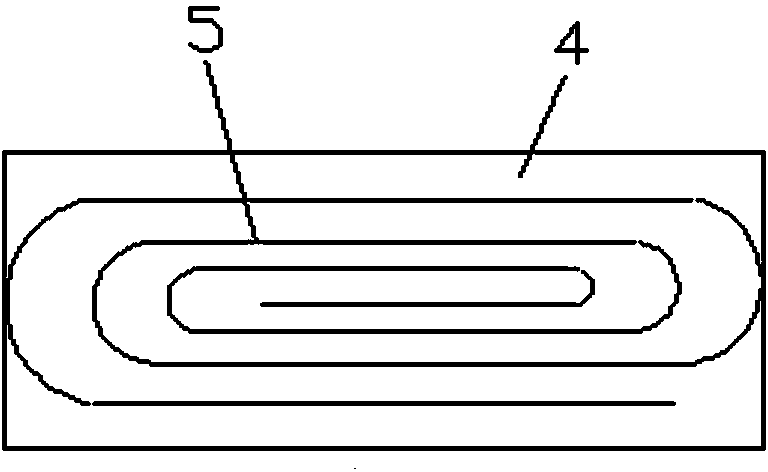

[0017] Such as figure 1 , figure 2 As shown, a drying device for textiles includes a box body 1 and a door 2 connected to the box body 1. At least two layers of metal mesh panels 3 are arranged in the box body 1. The metal mesh panels 3 have fast heat transfer and the metal mesh panels 3 can choose aluminum mesh board, but not limited to this kind of material, the preferred metal mesh board 3 of the present invention is three layers, is convenient to shelve a plurality of textiles, and drying efficiency is high, and the bottom of three-layer metal mesh board 3 is provided with The shelf 4 is provided with a ring-shaped electric heating tube...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap