Multi-target-proportion vehicle body vibration characteristic comprehensive test platform

A technology of comprehensive test bench and proportional car body, which is applied in the field of testing device for dynamic characteristics of high-speed train car body structure, can solve the problems of monotonous test methods, inability to comprehensively and effectively study the equivalence of structural strength and stiffness of lightweight structures, and no Seeing problems such as the test bench for the vibration characteristics of the proportional vehicle body, the effects of overcoming the test cost, small structure scale and cost reduction were achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

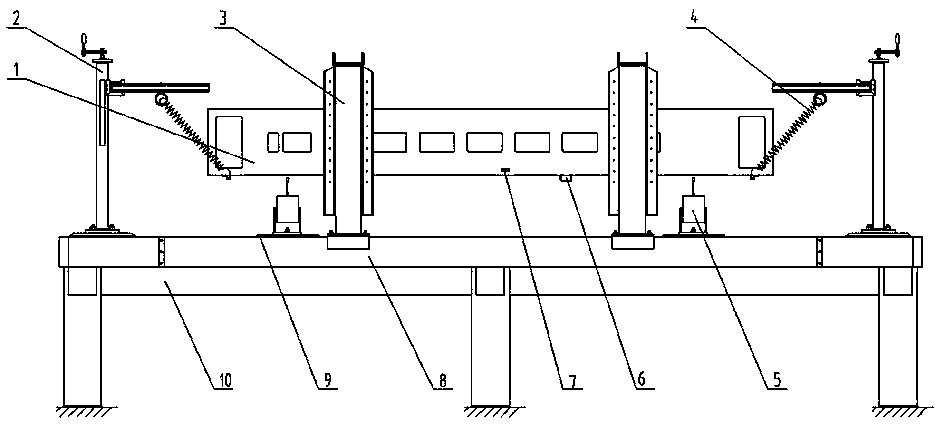

[0025] to combine figure 1 As shown, the proportioned aluminum alloy car body 1 is suspended on the end hanger 2 of the underframe 8 of the test bench through springs. The end hanger includes screw rod, long cantilever, spring seat hole, and the screw rod in the end hanger is used to adjust the height of the proportional car body and fix the proportional car body in the desired position. The height of the screw can be adjusted freely, and a long cantilever is welded on the screw to prevent the proportional car body from touching the end hanger during the test. The middle part of the long cantilever is welded with a spring seat hole, one end of the spring is fixed on the spring seat hole, and the other end is fixed on one side of the proportional car body, and the final proportional aluminum alloy car body is suspended by the spring on the end hanger on the bottom frame of the test bench.

Embodiment 2

[0027] to combine figure 2 As shown, the proportional car body is installed on the underframe of the test bench through the movable intermediate hanger 3, and the specific function is to realize two kinds of hanging support methods for the comparative car body, so as to realize the test and analysis of the torsional mode of the car body structure , and the position of the support point can be adjusted by moving the middle hanger. The scale body shown in the schematic is obtained by figure 1 Assembly is achieved by hanging the spring in it.

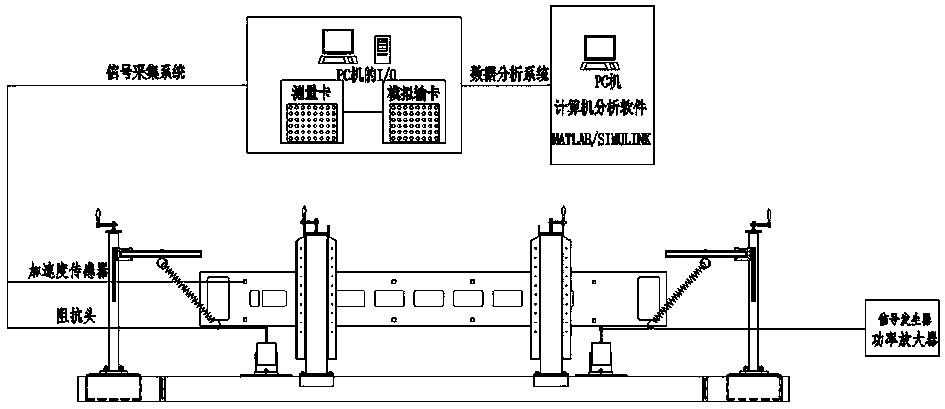

[0028] Different support and hanging methods are realized through the middle hanger of the test bench. Various force element sensors 6 (including displacement, acceleration, etc.), stress strain gauges 7 and signal lines for transmitting signals are installed on both sides of the proportional car body. It can realize the equivalence research of the dynamic strength and dynamic stiffness of the proportional car body structure of differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com