Rotary impact screwdriver with a striking mechanism

An impact mechanism and screwdriver technology, applied in screwdrivers, power tools, manufacturing tools, etc., can solve problems such as hindering screw insertion, damage to the screw head of the screw, obstruction, etc., and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

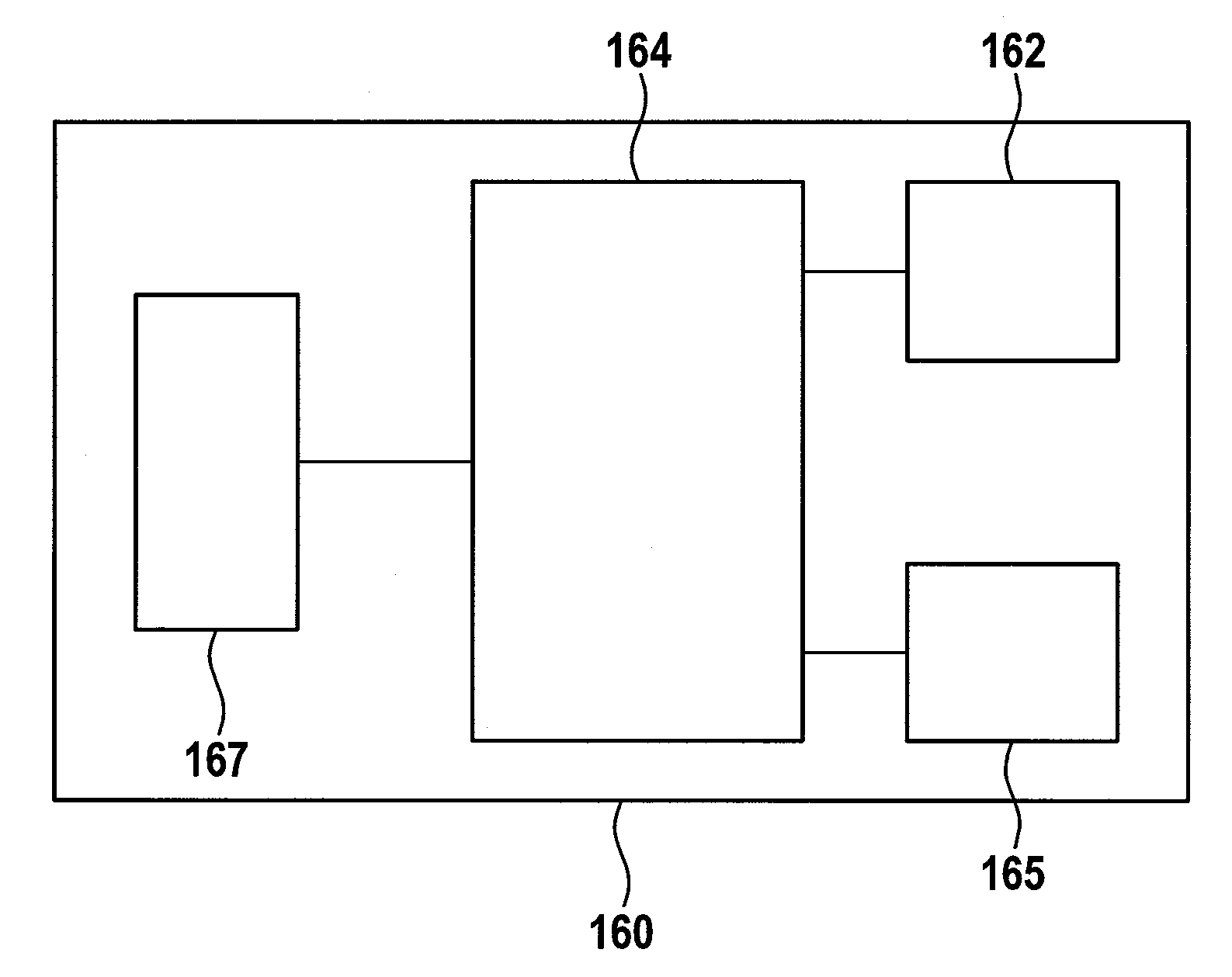

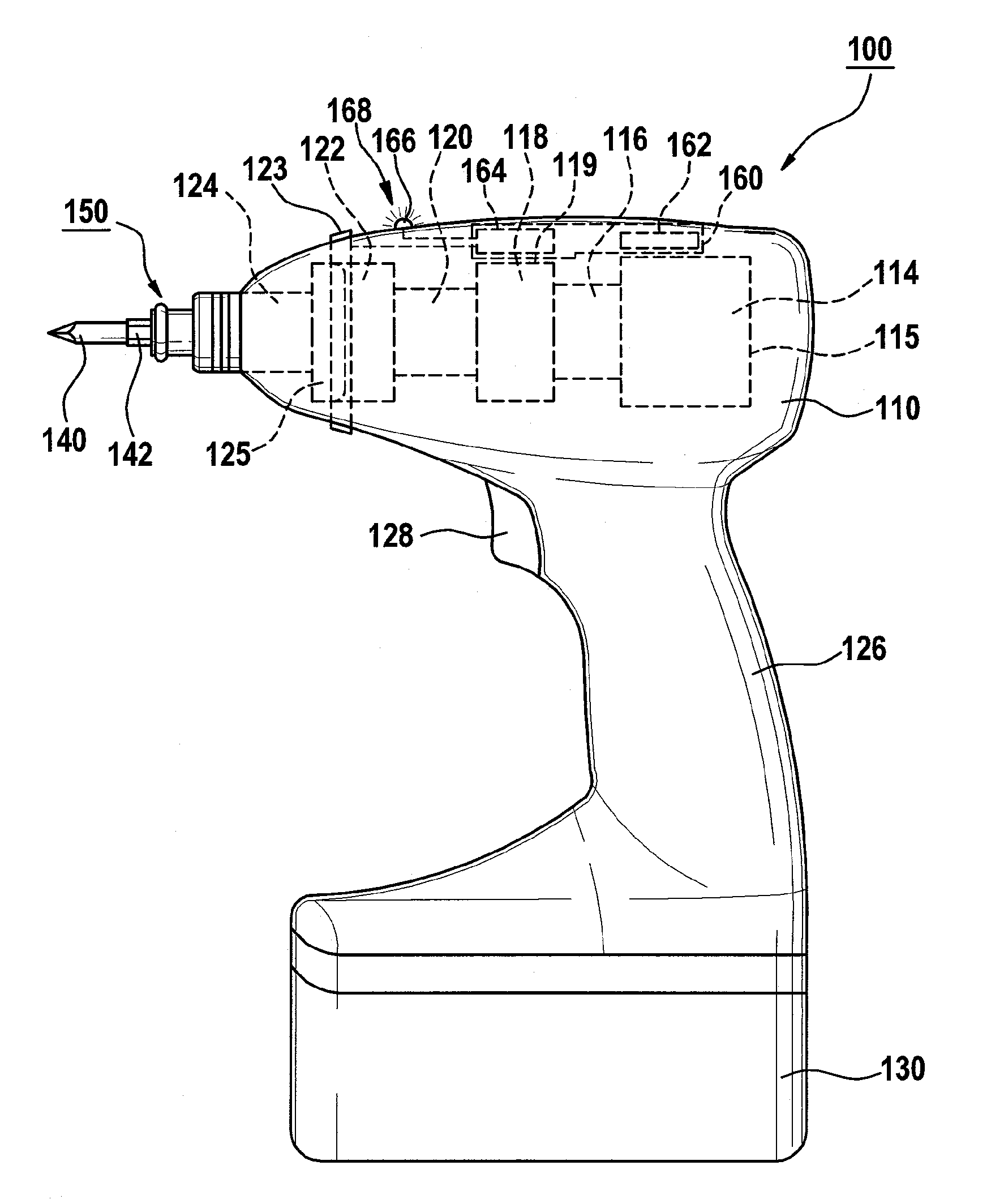

[0041] According to one specific embodiment, the sensor element 162 has a current sensor. In this case, the operating parameters detectable by the sensor element 162 are, for example, at figure 1 The motor current flowing in the drive motor 114 . The motor current at figure 1 The rotational impact of the screwdriver 100 rises during operation if, for example, in so-called "hard" screwing situations figure 1 The workload on the insert tool 140 rises. Thus, for example, if the motor current exceeds a predetermined threshold value, the motor current can be detected on the basis of a current sensor of the control unit 164 , which is arranged, for example, in the feed line to the drive motor 114 determined on the appropriate for converting to figure 1 The switching time of the impact operation of the impact mechanism 122.

[0042] Additionally or alternatively, sensor element 162 has a torque sensor. In this case, an operating parameter detectable by the sensor element 162 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com