Rolling bearing with three-arc roller surface

A rolling bearing, three-arc technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problem of serious friction between rollers and ferrule raceways, so as to improve bearing life, save production costs, and reduce the number of replacements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

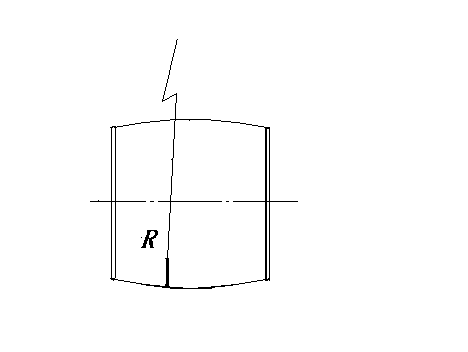

[0011] See attached figure 1 , the figure is a simplified structure diagram of the original roller surface arc, and the arc R is the arc radius of the roller surface.

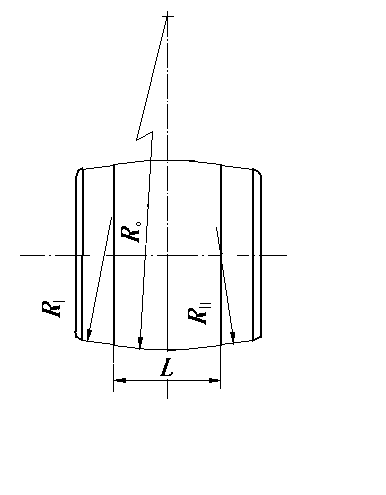

[0012] See attached figure 2 , which is a schematic structural diagram of the surface arc of the roller of the present invention, including the arc R. , R??, R????, where the arc R. Connect the left and right arcs R??, R??? to form a smooth arc. The arc R. The width of the chord is L.

[0013] Change the surface of the roller to three circular arcs to reduce friction and collision with the raceway of the ring. The arc of the surface of the roller and the arc of the raceway of the ring fit very well, which improves th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com