Novel extreme outer pressure test device and method for hemispherical concrete shell

A test device and hemispherical shell technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve problems such as complex structural forms, concrete hemispherical shell rupture, and scientific experimental research on prototype structures that are difficult for engineers and technicians to achieve improvement. The effect of resilience to accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

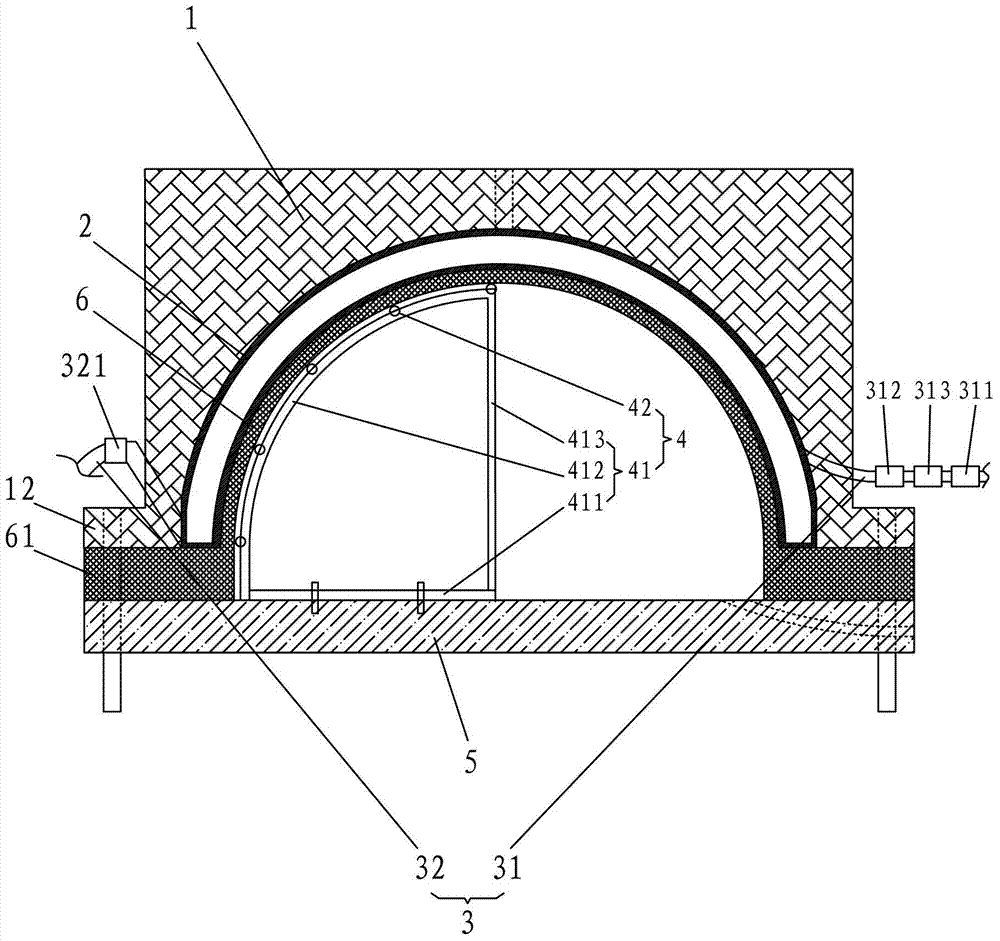

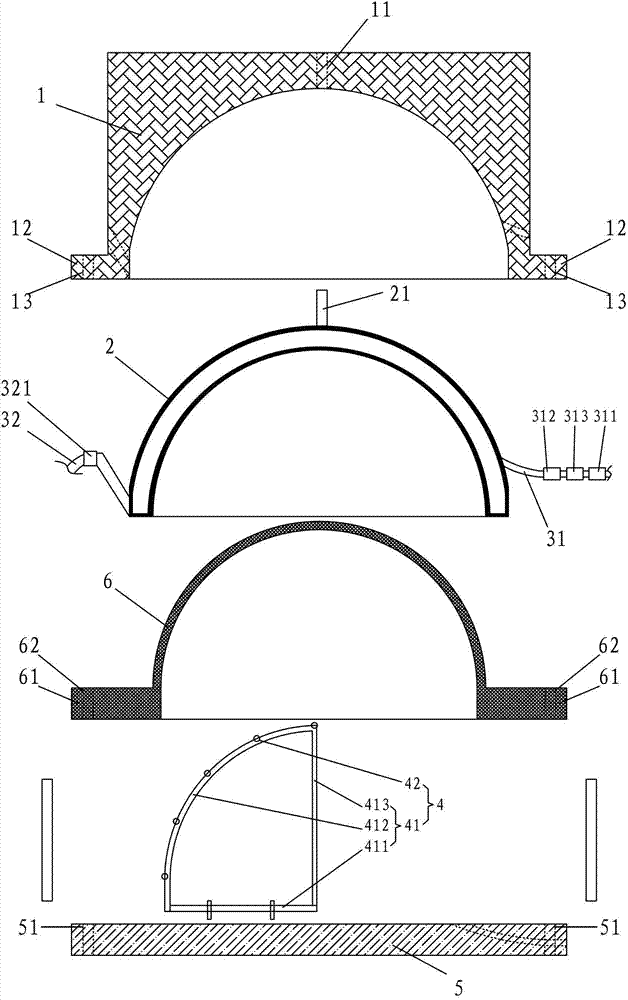

[0033] A novel limit external pressure testing device for a concrete hemispherical shell of the present invention, when in use, usually the top of the arc faces upwards, such as Figure 1-3 As shown, it includes a fixed support cover 1, a capsule 2, a pressurizing device 3, a deformation detection device 4 and a data acquisition and processing device (not shown in the figure).

[0034]The fixed support cover 1 is set outside the concrete hemispherical shell 6 and there is a gap between the inner surface and the outer surface of the concrete hemispherical shell 6. The capsule 2 is arranged in the gap in the form of expansion, and the pressurizing device 3 pressurizes the capsule 2 To make it expand, the deformation detection device 4 is arranged on the concrete hemispherical shell 6 to detect the deformation of the concrete hemispheri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com