Leaf spring and electric connector

A technology of electrical connectors and leaf springs, applied in the field of leaf springs, can solve the problems of affecting the life of plugging and unplugging, easy deformation, poor overcurrent capability of electrical connectors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

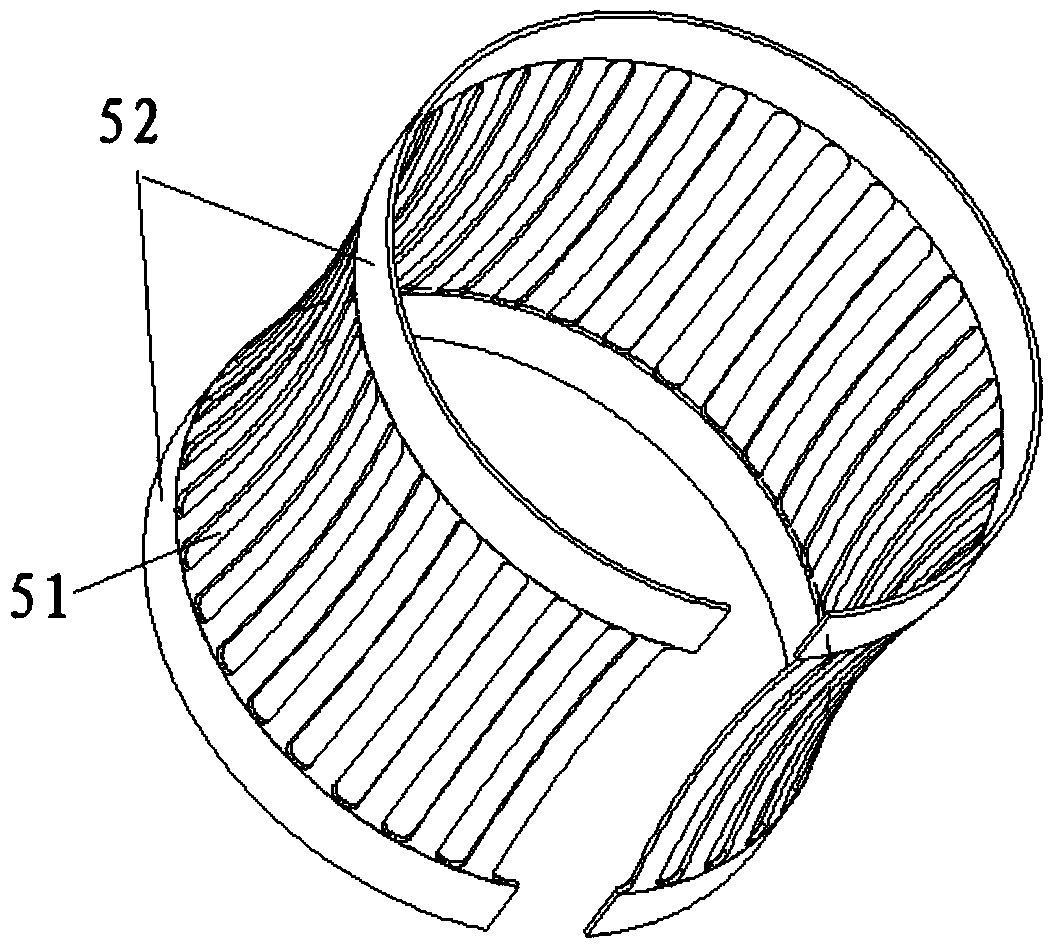

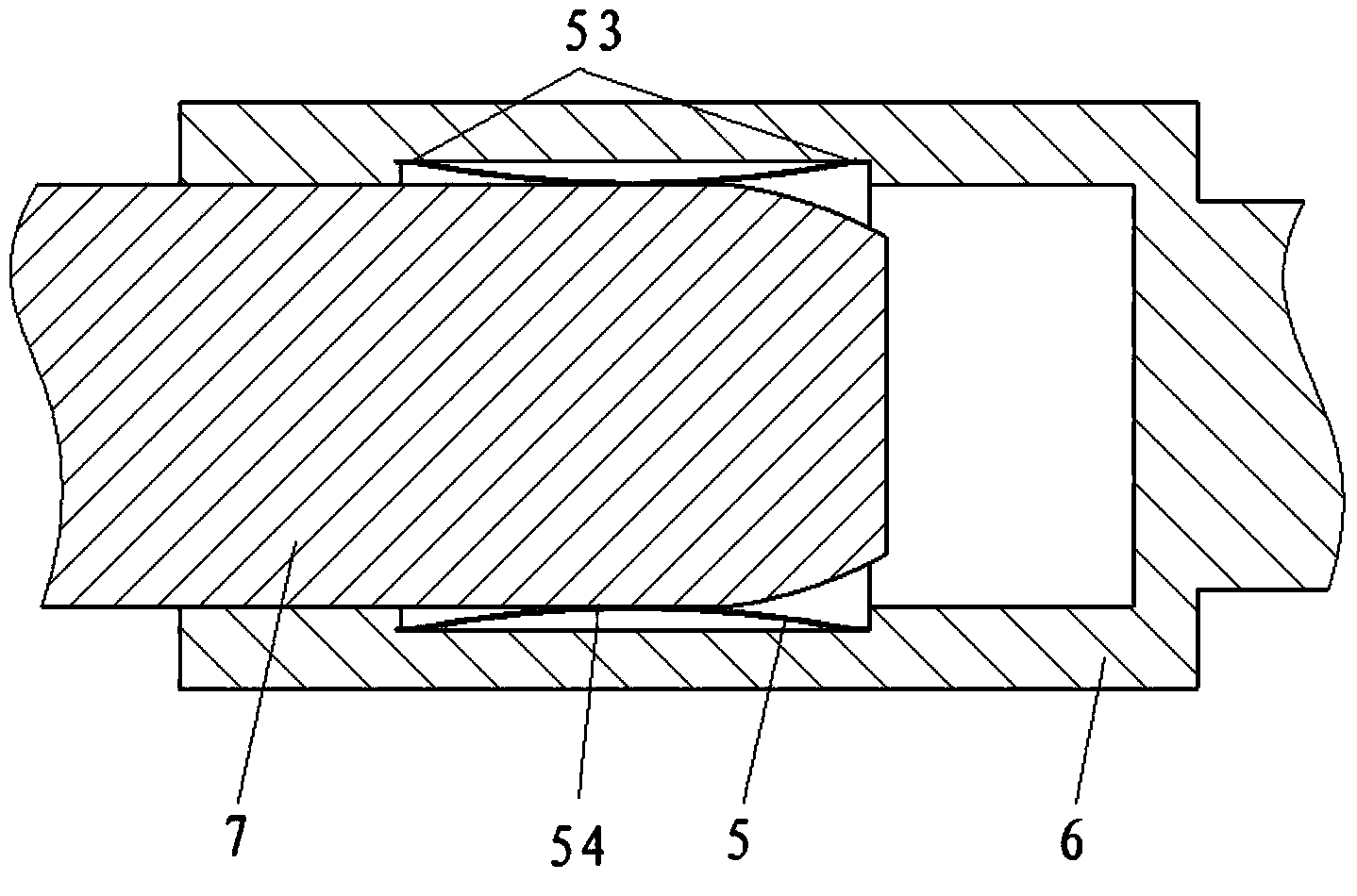

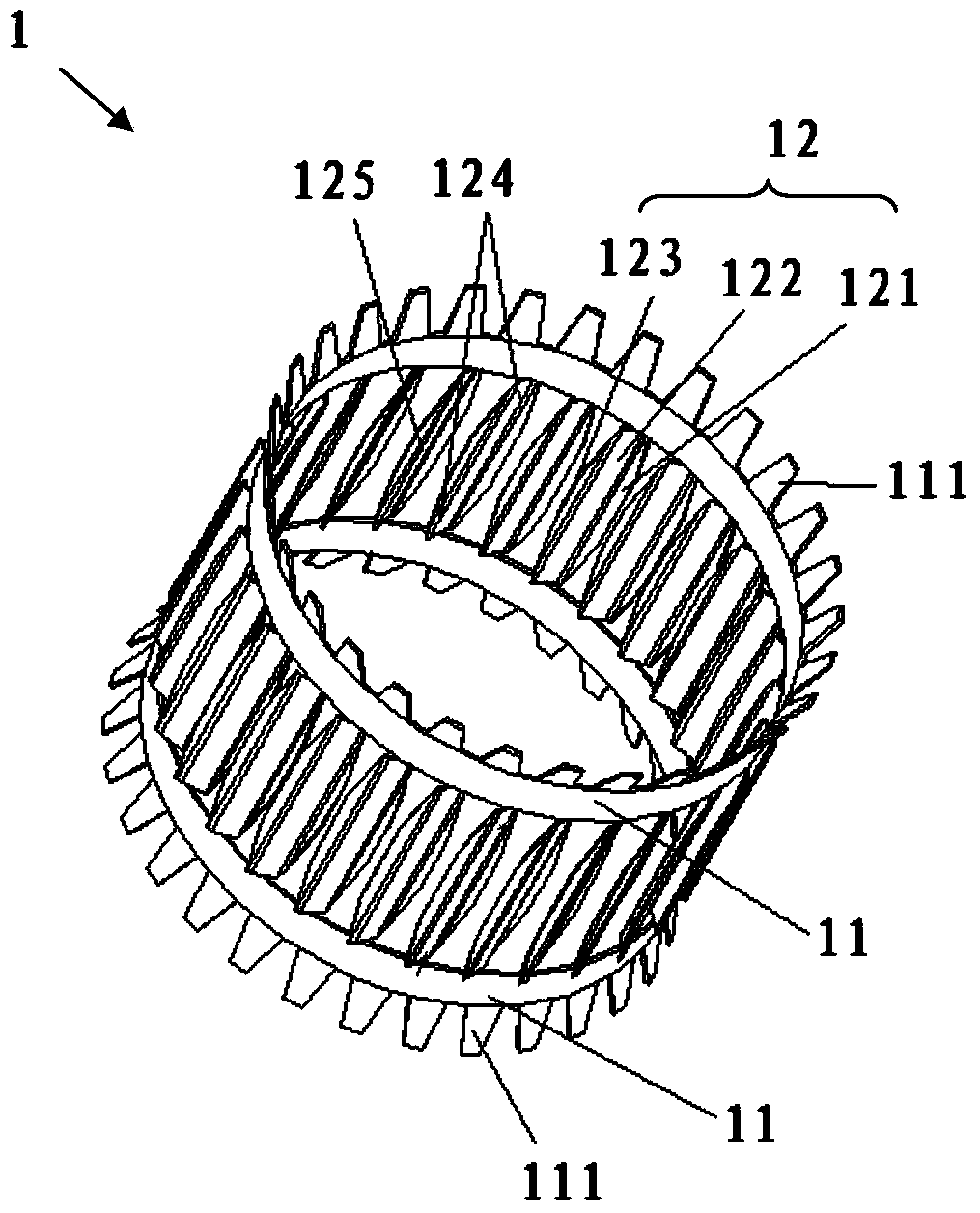

[0027] Such as Figure 3-5 As shown, the leaf spring 1 includes two connecting plates 11 and a plurality of elastic sheets 12, and the elastic sheets 12 include an inner contact plate 121, a transition plate 122, and an outer contact plate 123 connected in sequence, and the two ends of the transition plate 122 are connected to the two connecting plates respectively. 11 is fixedly connected, there is a distance between adjacent two elastic pieces 12 (that is, adjacent two elastic pieces do not touch), the first circumferential surface 126 where the inner contact plate 121 of each elastic piece 12 is located, and the first circumferential surface 126 where the outer contact plate 123 of each elastic piece 12 is located. The two circumferential surfaces 127 are arranged coaxially. The leaf spring 1 can be manufactured by stamping integral moldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com