High-frequency switching power supply transformer

A high-frequency switching power supply and transformer technology, applied in the direction of transformer/inductor cooling, transformer/inductor parts, transformer/inductor coil/winding/connection, etc., to achieve matching optimization, heat dissipation improvement, and heat reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

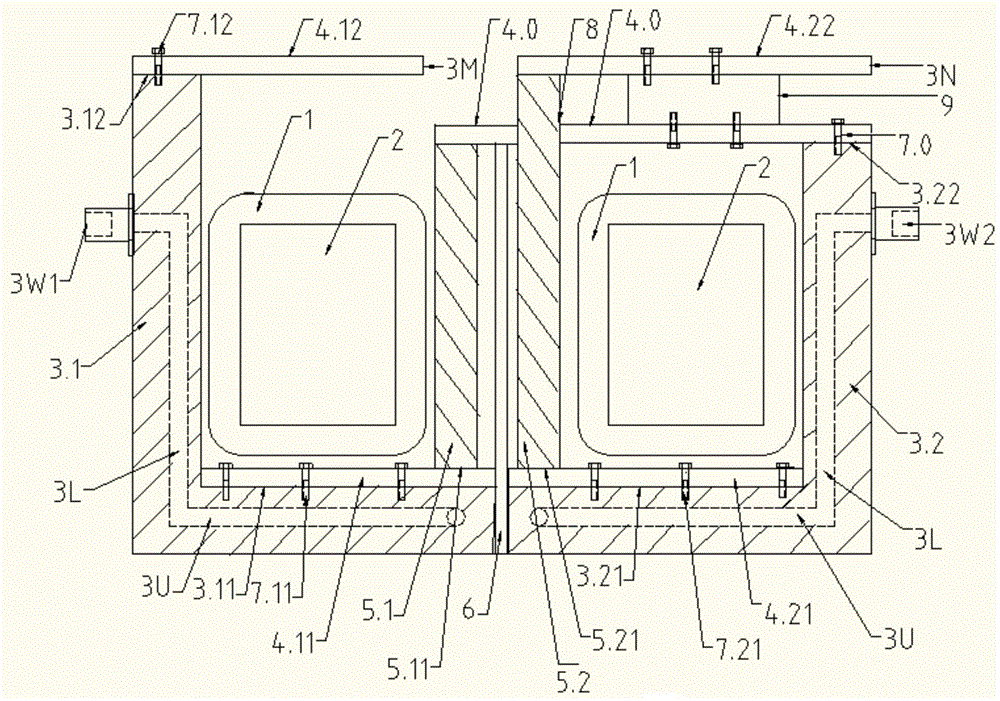

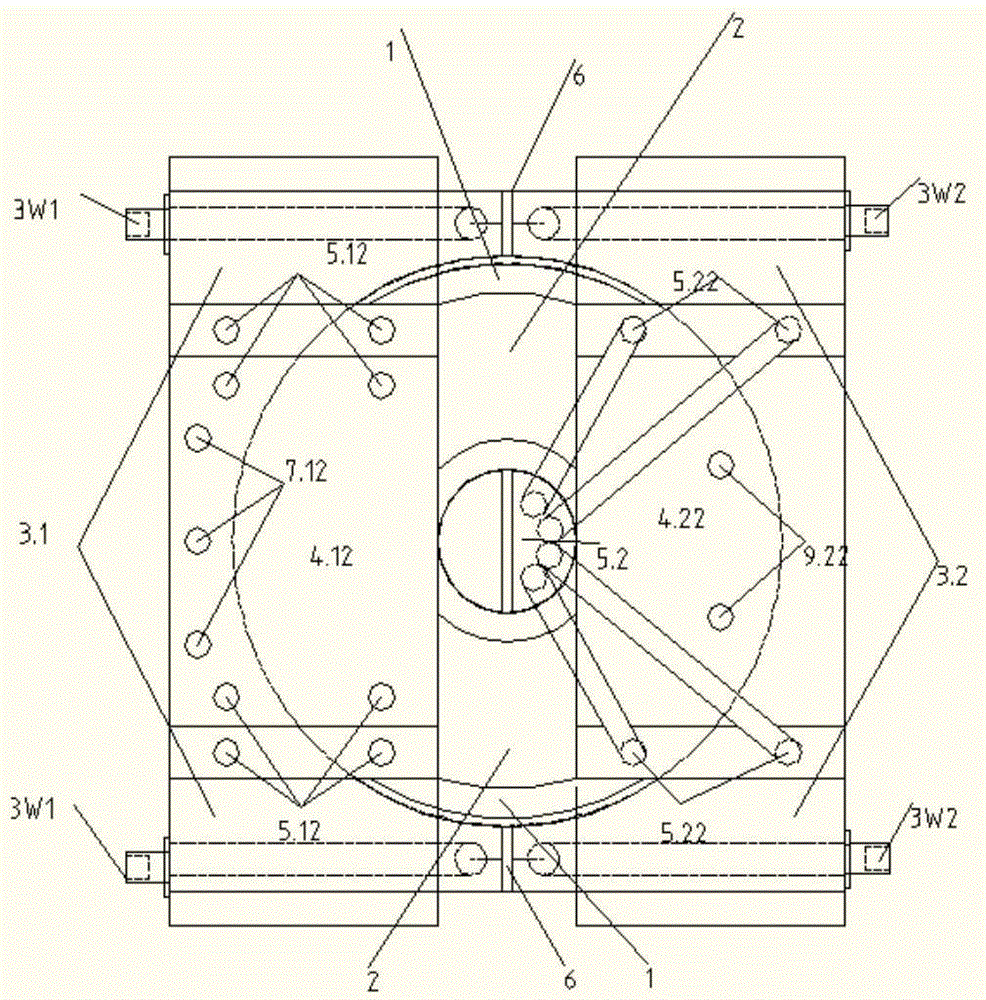

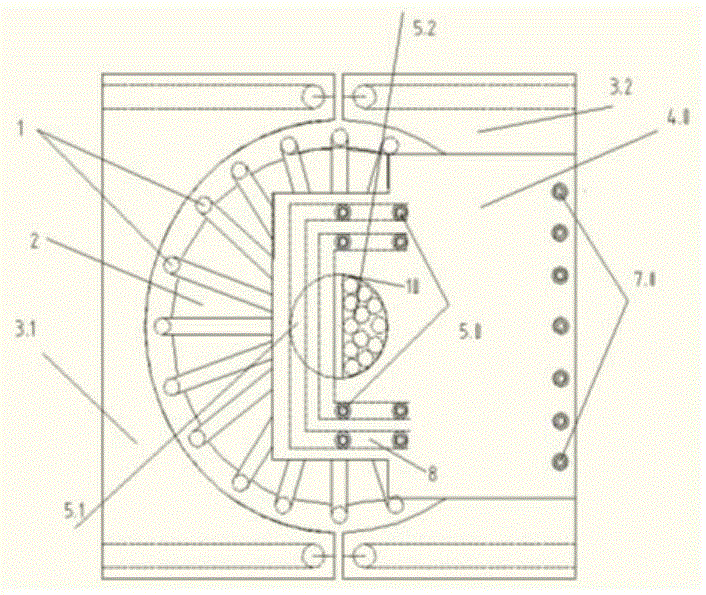

[0020] The composition of the high-frequency switching power supply transformer of this embodiment will be described below with reference to the accompanying drawings.

[0021] 1) see figure 1 , figure 2 , a left sheath 3.1 and a right sheath 3.2 made of copper and aluminum alloy are provided, and an insulating layer formed of high thermal conductivity silica gel 6 is formed between the two sheaths. See figure 1 , except that the left top surface 3.12 of the left sheath is higher than the right top surface 3.22 of the right sheath, the two sheaths have the same structural shape and size. Here, the left sheath 3.1 is taken as an example for illustration. See Figure 5 , The left sheath 3.1 is a rectangle with an equal-diameter semicircular cavity, a left base 3A with a semicircular left bottom surface 3.11; a semi-cylindrical 3B with a left top surface 3.12. A connected horizontal U-shaped water pipe 3U and two L-shaped water pipes 3L in the semi-cylinder are arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com