Full-breadth stamping device

A full-width, horizontal technology, applied in printing, stamping and other directions, can solve the problems of inability to achieve full-width stamping, inconvenient use, limited specifications, etc., and achieve the effect of rapid seal change and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments described below are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

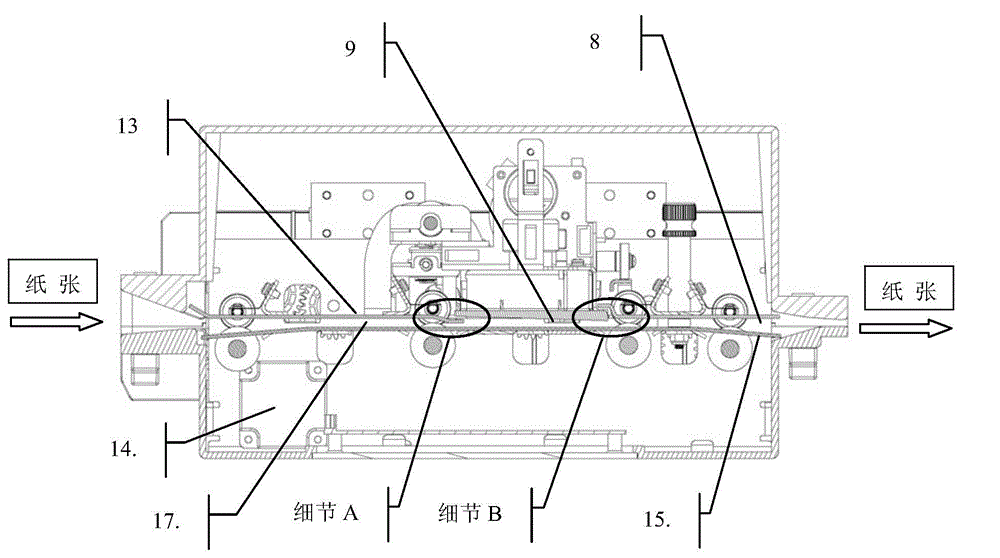

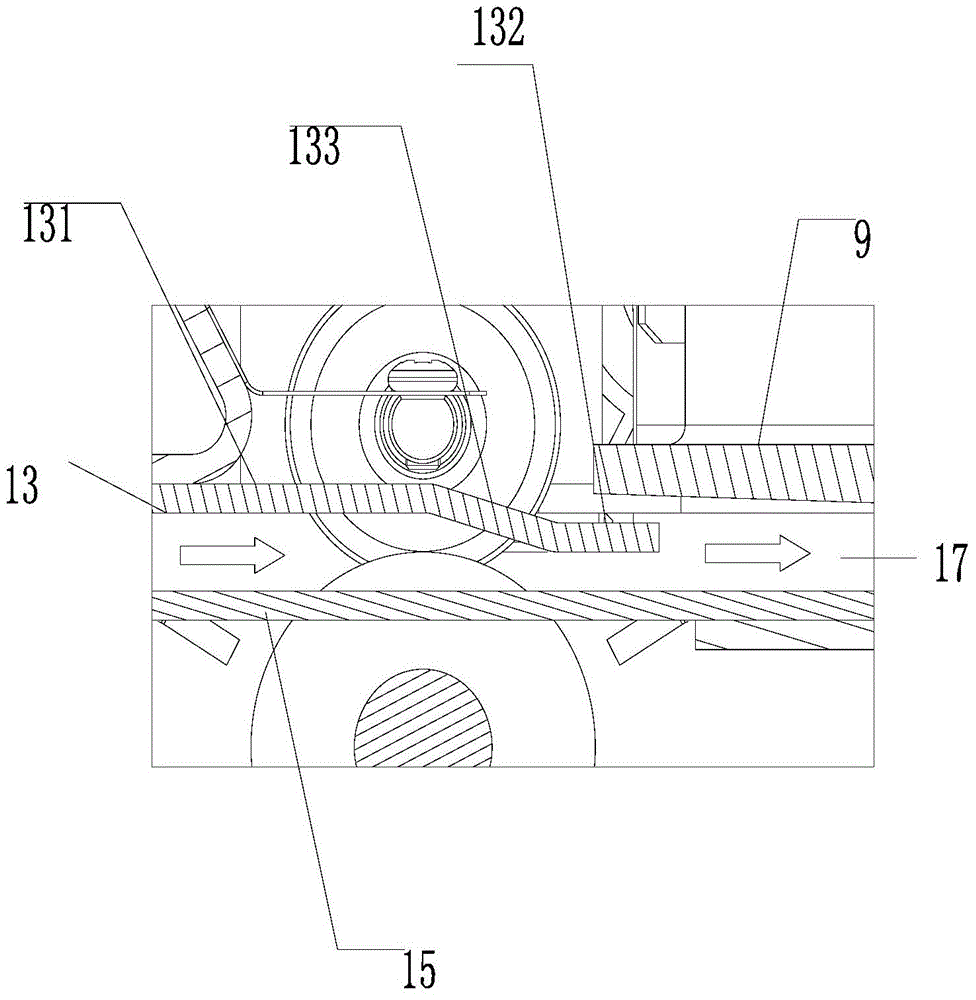

[0017] The present invention is a full-width stamping device. When paper enters the paper inlet of the device, full-width stamping in the X and Y axis directions of the paper can be realized. After the stamping is completed, the paper is output from the paper outlet of the device; The tile-shaped design can effectively prevent paper jams in the passage, and can support paper of various specifications such as A4 and B4; and its chapter changing mechanism adopts a hand-twist detachable design, which has the characteristics of quick chapter changing and maintenance.

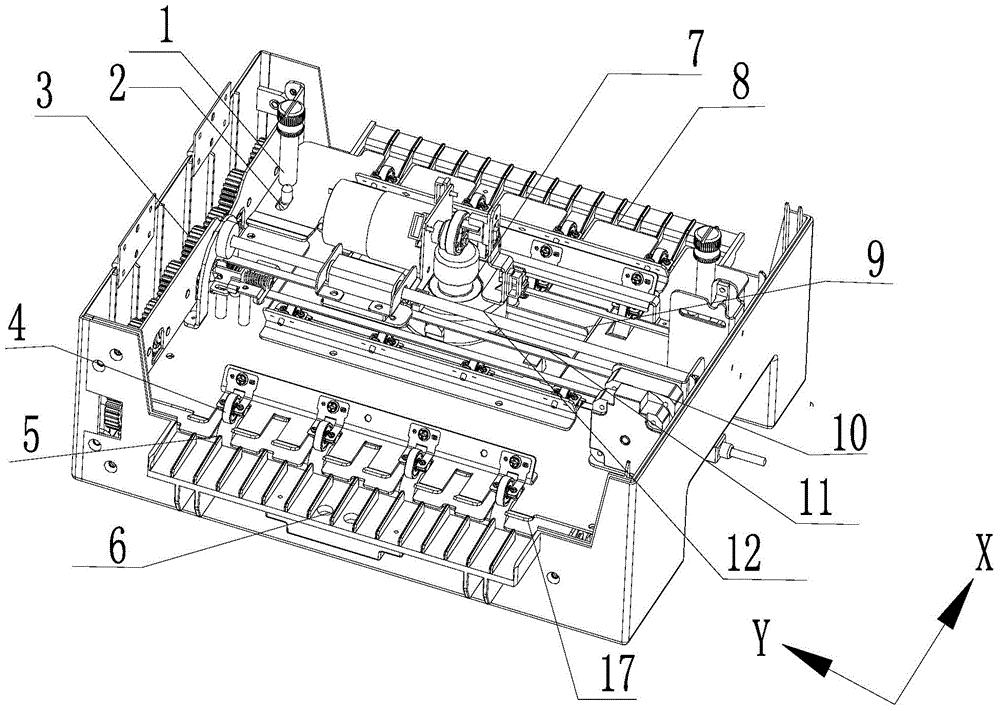

[0018] figure 1 It is a schematic diagram of the internal structure of a full-format stamping d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com