Transmission System of Oil/Electric Hybrid Rotary Drilling Rig

A rotary drilling rig and hybrid power technology, applied in the field of vehicle manufacturing, can solve the problems of low transmission efficiency, energy recovery rate and reuse rate, and achieve the effects of promoting energy saving and environmental protection, improving energy saving effect, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

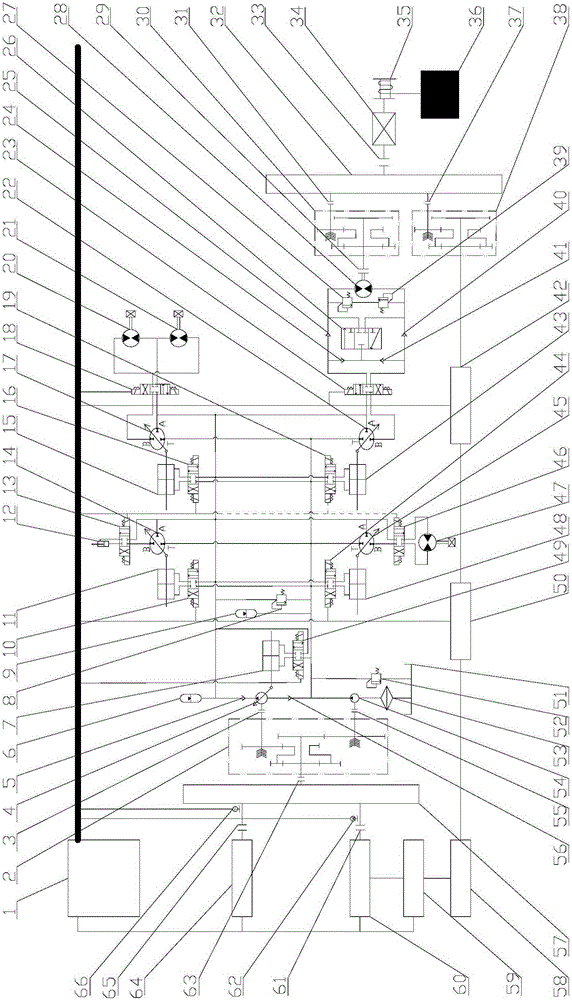

[0020] See attached figure 1 , the transmission system of the oil / electric hybrid rotary drilling rig of the present invention includes a power system, a pressurization system, a power head system, a slewing system and a winch system;

[0021] The power system includes engine 64, motor / generator II 60, supercapacitor 58, rectifier or inverter II 59, rectifier / inverter I 50, motor / generator I 42, clutch IX 65, torque coupler II 57, clutch VIII 63, transmission Box I2, clutch I3, variable pump 4, clutch VII61, clutch VI55 and quantitative pump 54; engine 64 and motor / generator II60 are connected in parallel to the torque coupler II57 through clutch IX65 and clutch VII61 respectively, and through rotation The shaft is connected to the gearbox I2 through the clutch Ⅷ63. The gearbox I2 is connected to the variable pump 4 and the quantitative pump 54 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com