A cloth grinding process

A technology of grinding and crafting, applied in textiles and papermaking, roughening, fabric surface trimming, etc., can solve the problems of weak three-dimensional effect of clothing patterns, great human injury, skin allergies or poisoning, etc. Vivid image and good three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments.

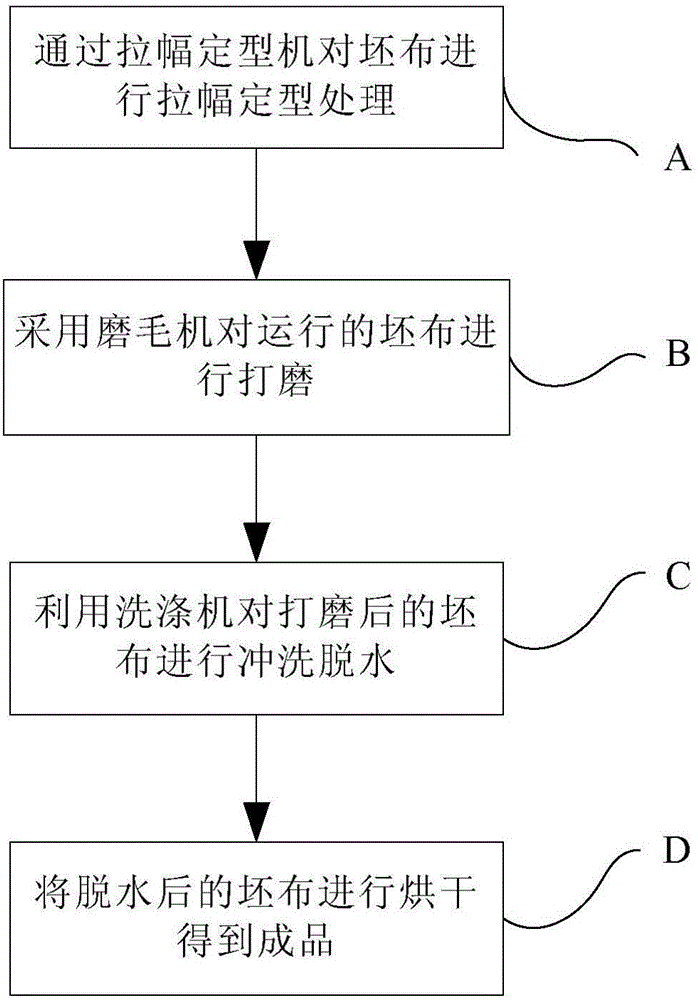

[0022] Such as figure 1 As shown, the present embodiment discloses a cloth embossing process, which includes the following steps:

[0023] A. Pretreatment: The gray cloth is subjected to stenter setting treatment by a stenter setting machine. The stenter setting machine soaks the gray cloth in the trough with chemical materials, and after being evenly squeezed by the rollers, it enters the oven. When the gray cloth passes through the oven, it will be dried and shaped under the action of high-temperature hot air, and the gray cloth after entering the shape has a good feel. and stable size.

[0024] The tenter setting treatment process includes a softening treatment and a drying treatment process. During the processing of the fabric, the handle will become rough after repeated treatments, and the general synt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com