Multistage grouting concrete filling pile and construction process thereof

A cast-in-place pile and concrete technology is applied in sheet pile wall, foundation structure engineering, construction and other directions to achieve the effect of improving the performance of the pile body, saving the project cost and facilitating the construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

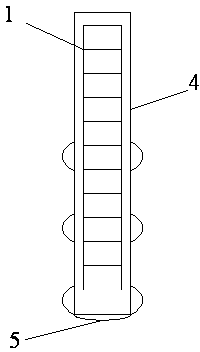

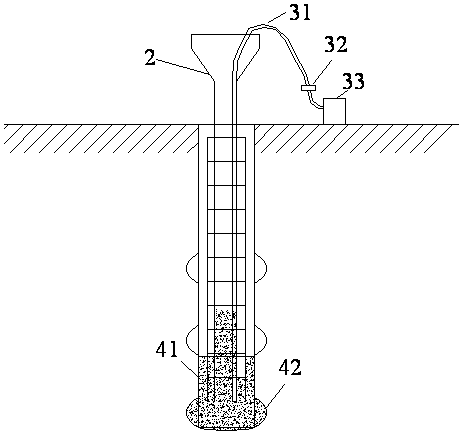

[0025] Embodiment: multistage grouting concrete pouring pile 4 (see attached figure 1 , 2 ), including a pile body 41, the outer surface of the pile body 41 is provided with two enlarged joints 42, and the enlarged joints 42 are fixedly connected with the pile body 41, and a pile tail 5 is provided under the pile body 41, so that The pile tail 5 is fixedly connected with the pile body 41, the diameter of the enlarged joint 42 is greater than the diameter of the pile body 41, the diameter of the pile tail 5 is greater than the diameter of the pile body 41, and the inside of the pile body 41 is set There is a reinforcement cage 1, and the reinforcement cage 1 is fixedly connected with the pile body 41.

[0026] The construction technology of the multi-stage grouted concrete pouring pile includes the following steps:

[0027] (a) Use a drilling machine to drill pile holes that meet the requirements at the construction location of the cast-in-situ pile;

[0028] (b) put reinfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com