High-temperature-resisting and wear-resisting coal-to-liquid special valve

A coal-to-oil, high-temperature-resistant technology, applied in the mechanical field, can solve the problems of stuck sealing, easy coking, leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will now be further described with reference to the drawings.

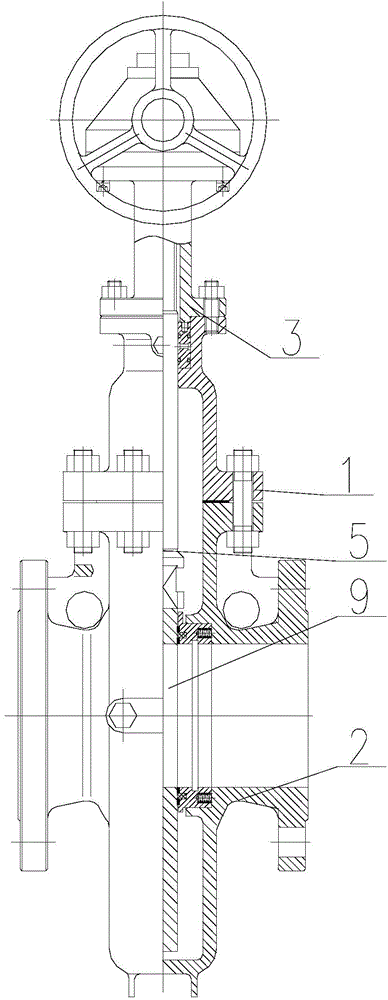

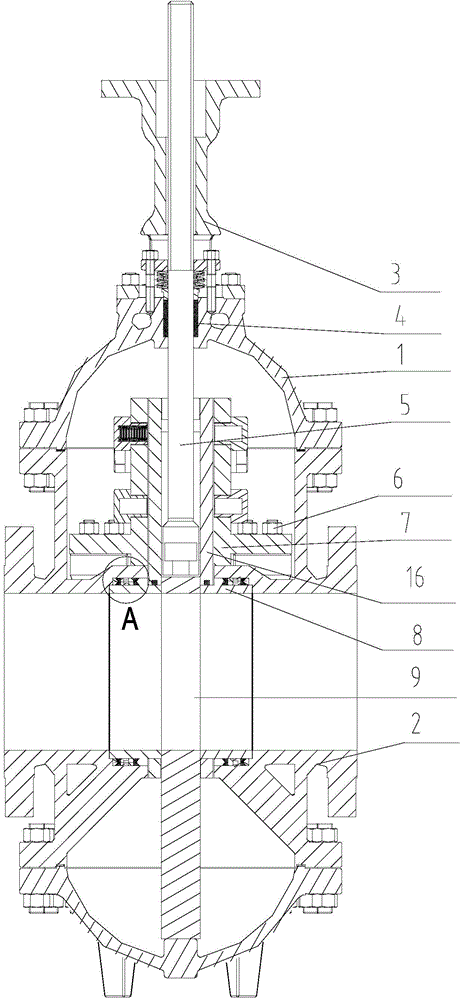

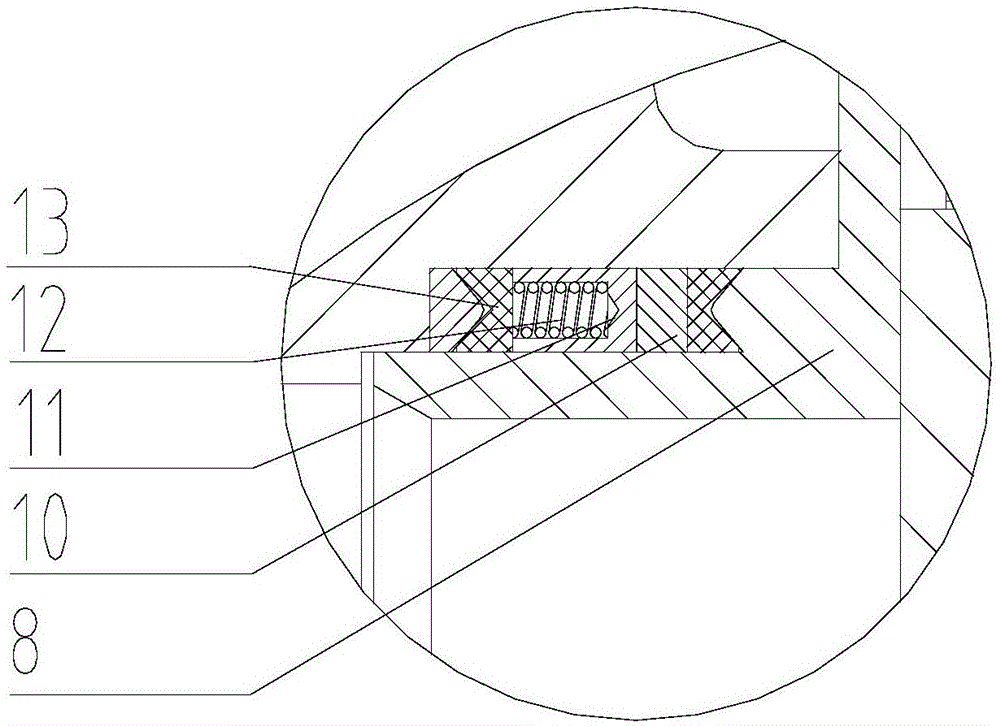

[0025] See figure 2 , The present invention includes a valve cover, a valve body, a bracket, a valve stem and a gate, and is characterized in that the protective outer cover 7 is fixed on the upper end of the inner cavity of the valve body 2, and the upper end of the protective inner cover 16 is embedded in the protective outer cover 7, and the protective The inner cover 16 is sleeved on the movable valve seat 8. The other side of the movable valve seat 8 is embedded in the inner cavity of the valve body 2. A gate 9 is arranged between the two movable valve seats 8, and the bottom of the gate 9 is fixed on On the valve body 2, the top end of the gate plate 9 is connected to the bottom of the valve stem 5. The lower end of the valve stem 5 is embedded in the protective inner cover 16, the upper end of the valve stem 5 is embedded in the valve cover 1, and the top end of the valve stem 5 C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com