Liftable transfer trolley with metal armored movable switchgear

A switchgear and metal armoring technology, which is applied in the field of liftable transfer trolleys, can solve the problems of reduced work efficiency, cost increase, deviation, etc., and achieve the effects of saving costs, improving work efficiency, and reducing the number of uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

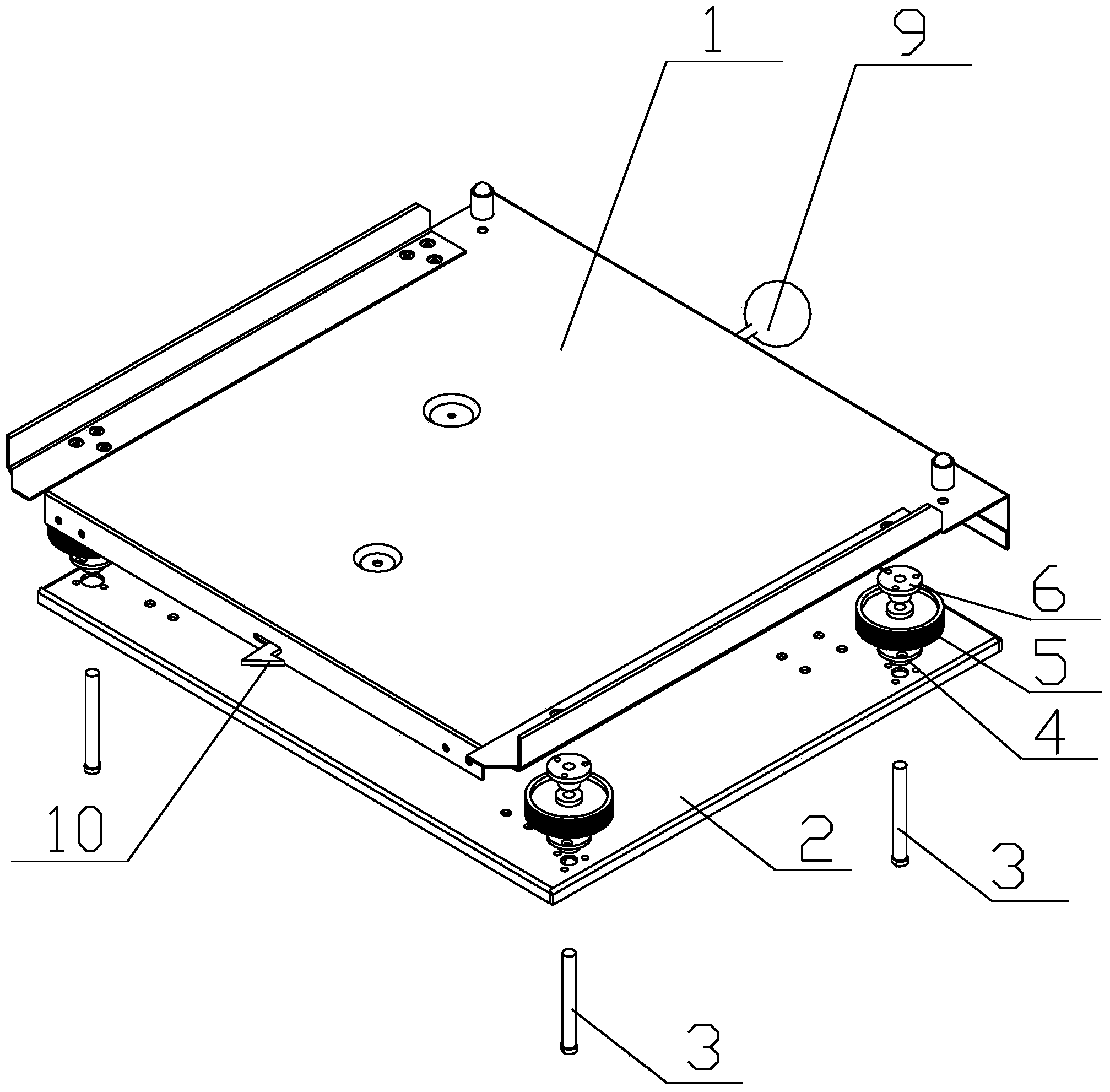

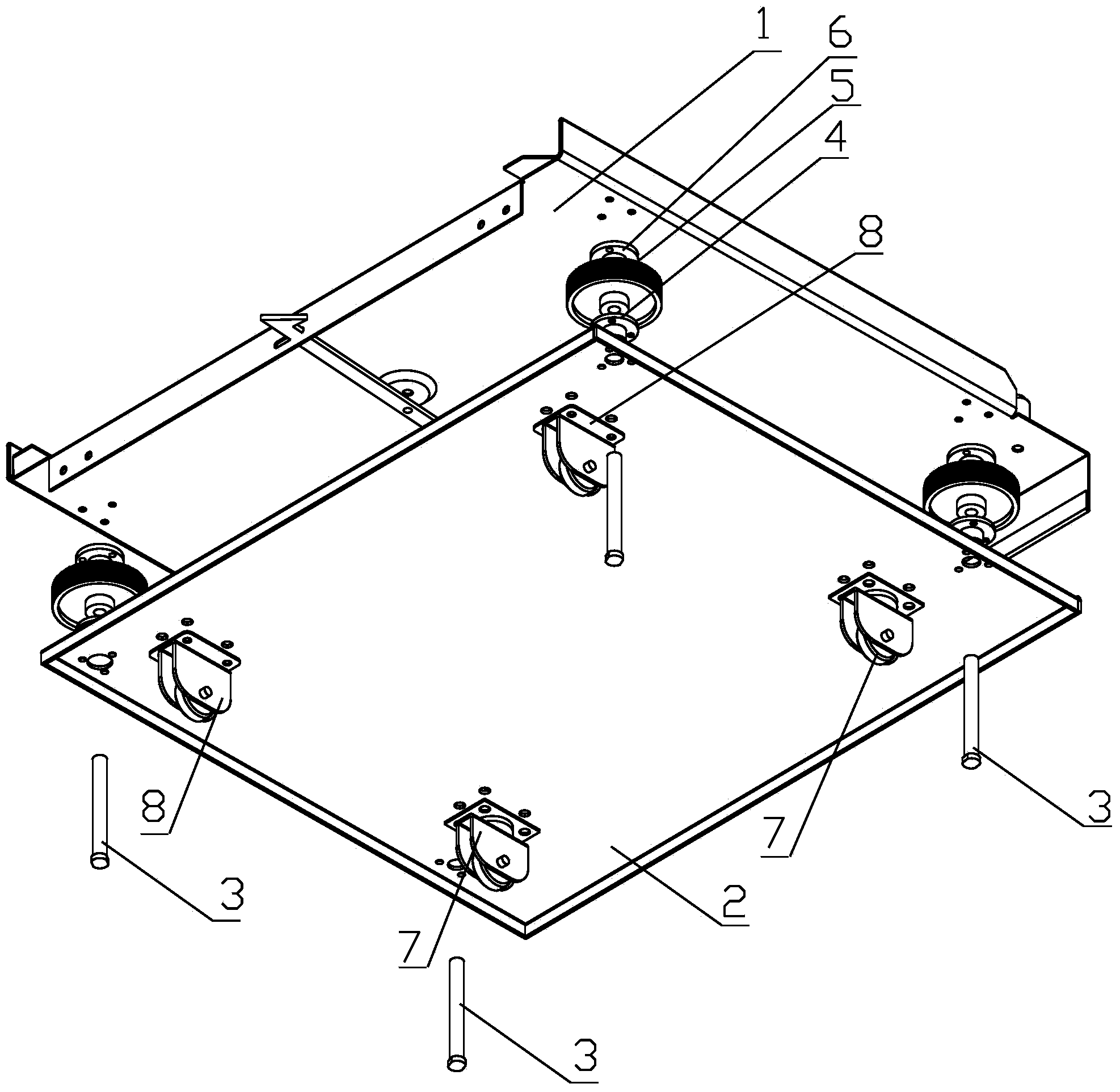

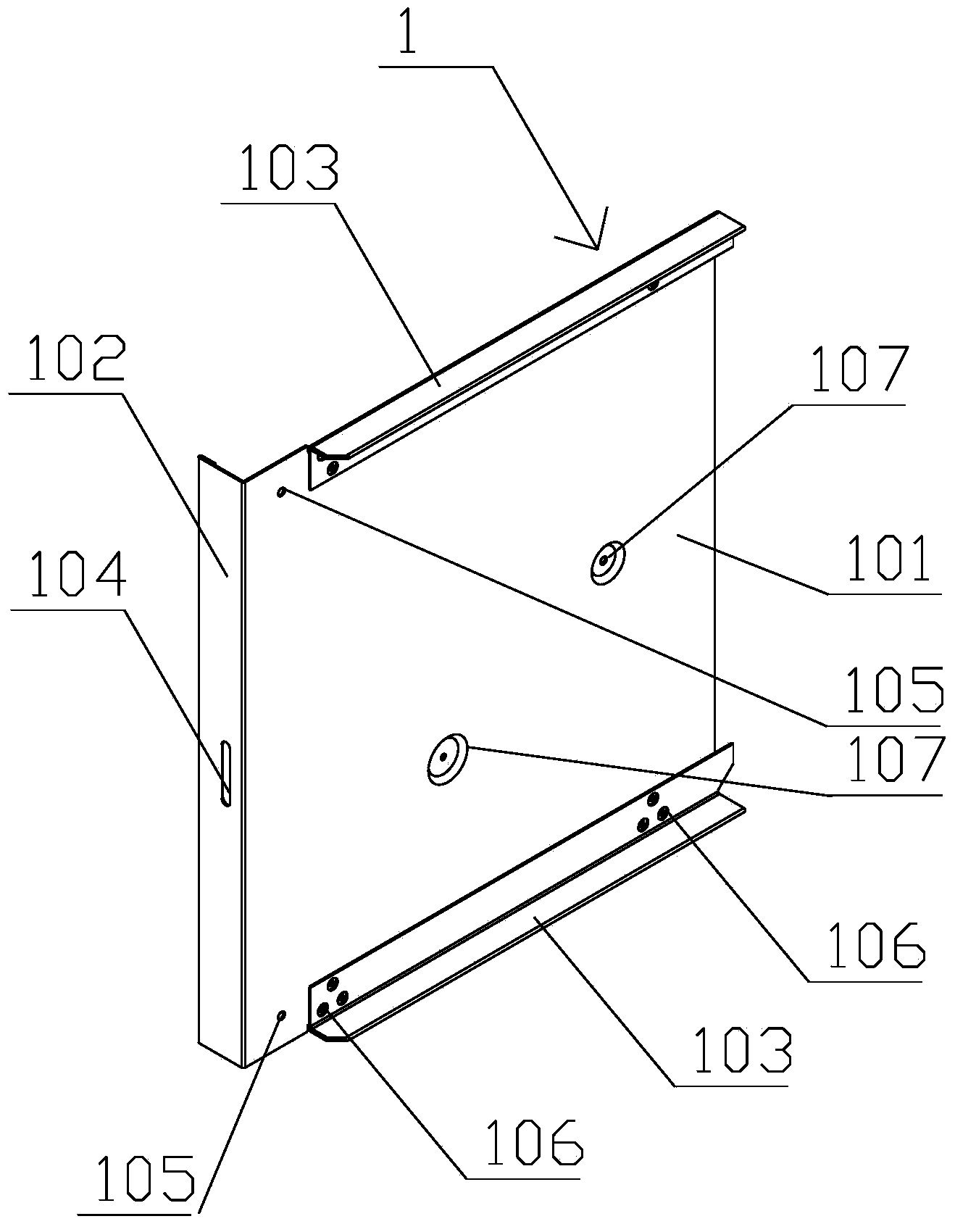

[0029] figure 1 It is one of the schematic diagrams of the three-dimensional structure of the liftable transfer trolley equipped with metal armored removable switchgear provided by the present invention, figure 2 The second schematic diagram of the three-dimensional structure of the liftable transfer trolley equipped with metal armored removable switchgear provided by the present invention. Such as Figure 1-2 As shown: the liftable transfer trolley equipped with metal armored removable switchgear provided by the present invention includes a supporting plate 1, a bottom plate 2 and a liftable mechanism between the supporting plate 1 and the bottom plate 2, and the lifting mechanism includes: a A lifting screw 3 that adjusts the lifting and is provided with external threads; a screw po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com