Electronic cam control device and electronic cam curve generation method

An electronic cam and control device technology, applied in the direction of electric controller, electric program control, non-electric variable control, etc., can solve the problems of slave axis vibration, the position of the slave axis servo motor cannot be completely followed, impact, etc., and achieve acceleration suppression. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

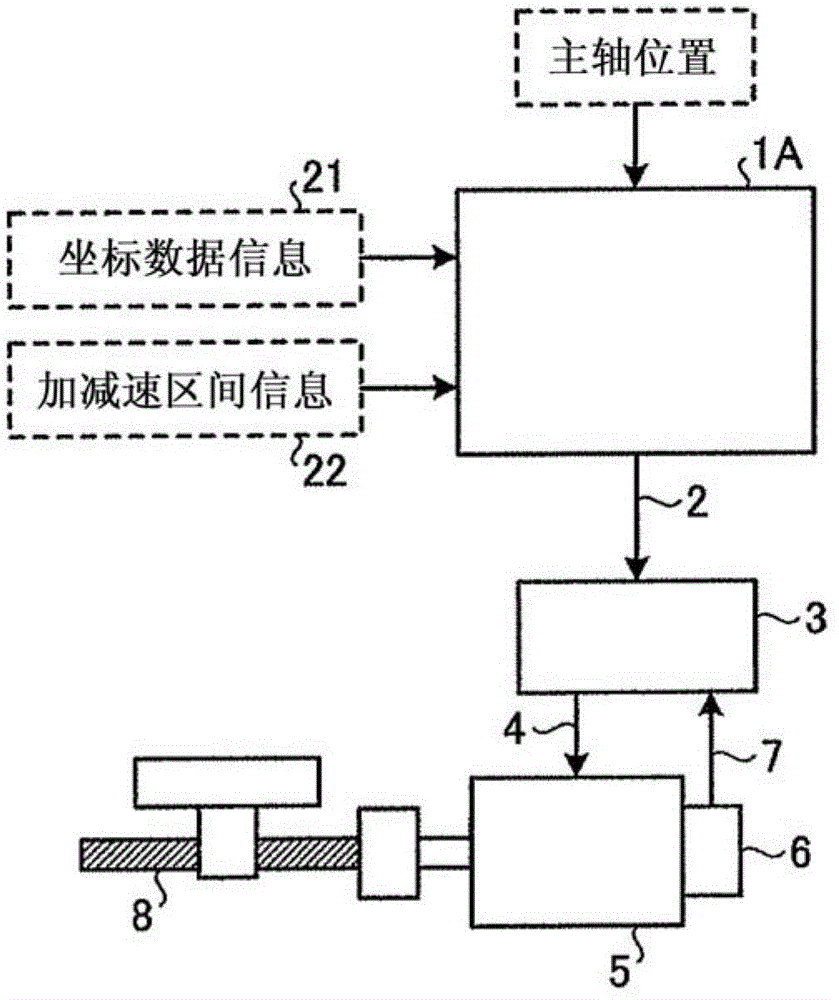

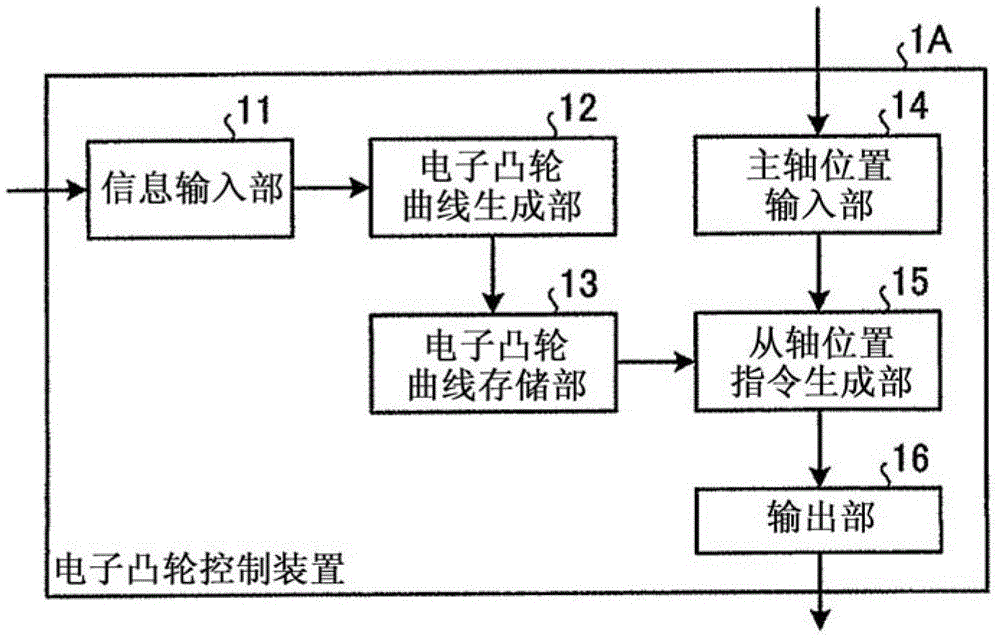

[0027] figure 1 It is a figure which shows the structure of the electronic cam system concerning Embodiment 1. The electronic cam system includes an electronic cam control device 1A, a servo amplifier 3 , a servo motor 5 , an encoder 6 , and a load mechanism 8 .

[0028] The electronic cam control device 1A is a device that generates an electronic cam profile and controls the servo amplifier 3 , the servo motor 5 , and the load machine 8 using the generated electronic cam profile. In the electronic cam system, by controlling the servo amplifier 3 with the electronic cam control device 1A, the servo amplifier 3 controls the servo motor 5 and thereby controls the load machine 8 .

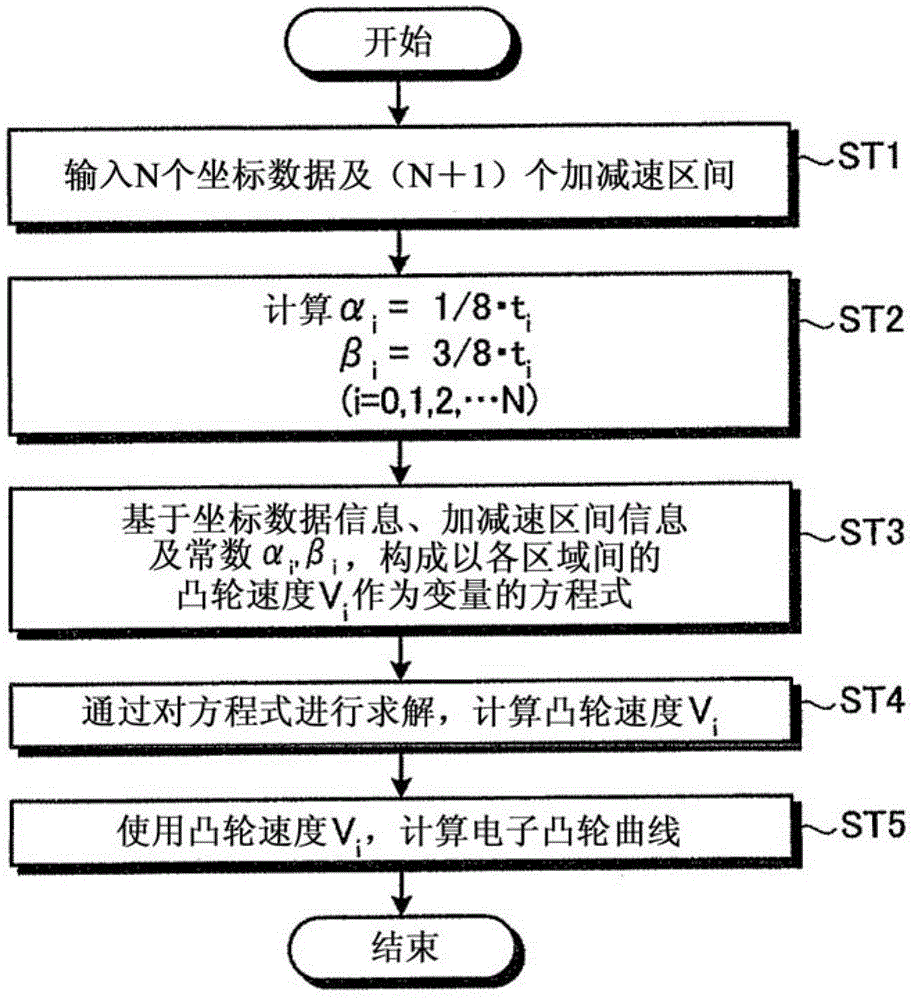

[0029] The electronic cam control device 1A generates an electronic cam curve based on coordinate data information 21 and acceleration / deceleration interval information 22 input by the user in advance, wherein the coordinate data information 21 specifies the positional relationship between the master...

Embodiment approach 2

[0164] Next, use Figure 7 and Figure 8 Embodiment 2 of the present invention will be described. In the electronic cam system according to Embodiment 1, in addition to the designated N coordinates, an electronic cam curve is obtained using (N+1) acceleration / deceleration intervals. The electronic cam system of this embodiment also obtains an electronic cam curve having the same properties as that of Embodiment 1, but instead of (N+1) acceleration / deceleration intervals, one parameter is used. Moreover, the electronic cam system automatically determines (N+1) acceleration and deceleration intervals according to a parameter, and then obtains the electronic cam curve.

[0165] Figure 7 It is a figure which shows the structure of the electronic cam system concerning Embodiment 2. for Figure 7 The realization and figure 1 The constituent elements of the electronic cam system according to Embodiment 1 shown with the same functions are denoted by the same reference numerals an...

Embodiment approach 3

[0216] Next, use Figure 9 to Figure 11 , Embodiment 3 of the present invention will be described. The electronic cam system of Embodiments 1 and 2 generates the following electronic cam curve, the waveform of which is the cam speed obtained by differentiating the position of the slave shaft with respect to the position of the main shaft, and the constant cam speed V in the adjacent area i , V i+1 between linear acceleration / deceleration. The electronic cam system of the present embodiment generates an electronic cam curve by connecting constant cam speeds in adjacent regions in an arbitrary curve that monotonically increases or decreases monotonically. In the present embodiment, an example will be described in which an electronic cam curve is generated by connecting constant cam speeds in adjacent regions in a continuous acceleration / deceleration curve. The electronic cam system of this embodiment generates, for example, an electronic cam curve in which the cam speed accel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com