Channel plate adapter and open-end spinning device with channel plate adapter

A channel plate and adapter technology, applied in the direction of free-end spinning machine, continuous winding spinning machine, spinning machine, etc., can solve the problems that the spinning quality cannot be fully improved, and the fiber guiding channel is difficult to manufacture, etc., to achieve contact Convenience, avoid adverse collision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to better clearly express the safety technical solution of the present invention applied in a specific situation, the present invention will be further described below in conjunction with the accompanying drawings.

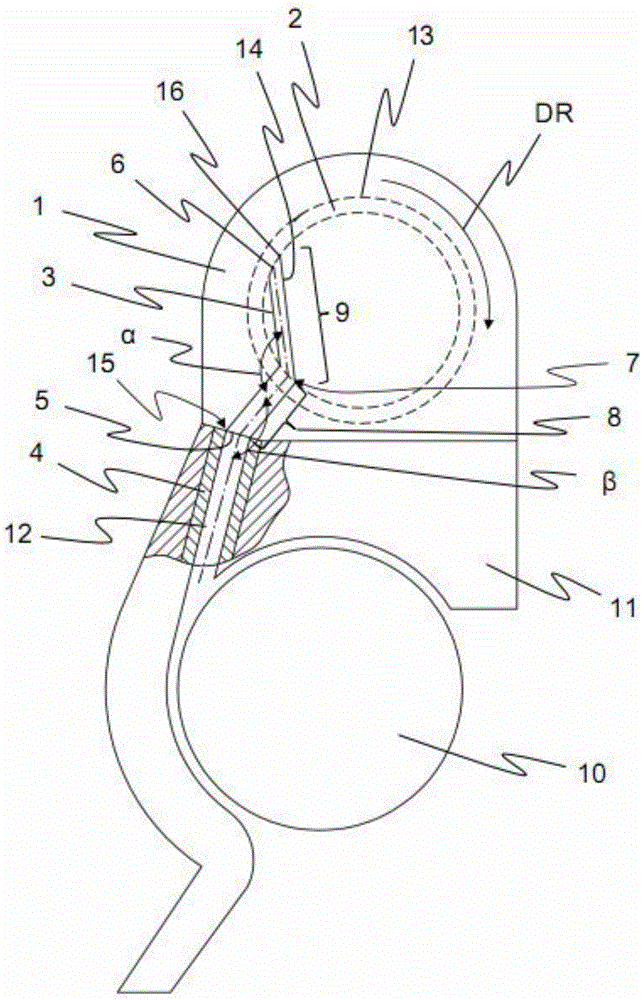

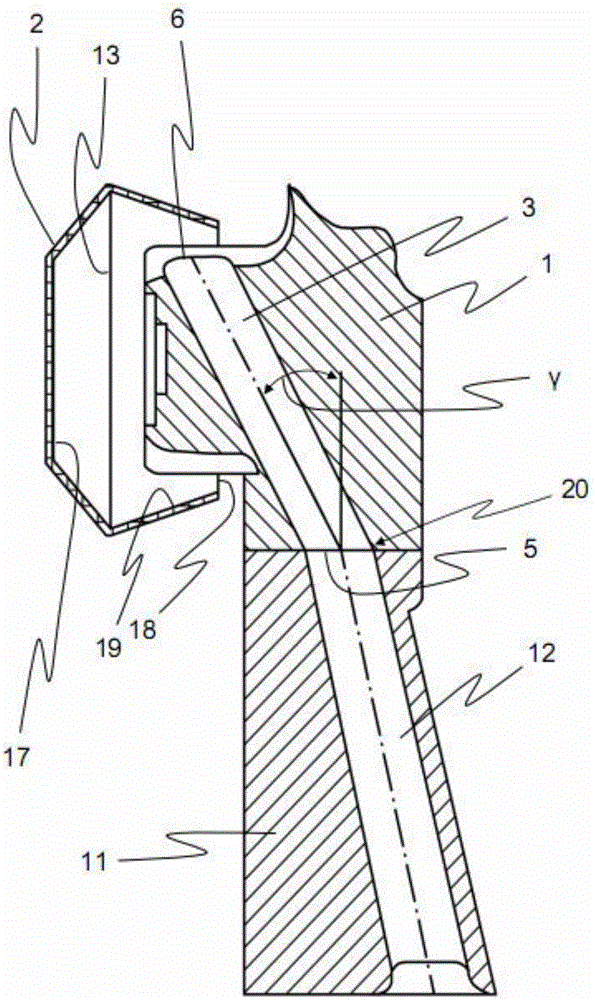

[0050] figure 1 Shown is a plan view of the opening roller 10 , the opening roller housing 11 , the fiber channel and the rotor cup 2 . A rotatable opening roll 10 is arranged in the opening roll housing 11, which opens the fiber bundle (not shown in the figure) to form individual fibers. Arranged in the opening roll housing 11 is a fiber introduction channel 12 which is preferably inserted as an exchangeable part 4 into the opening roll housing 11 . The opening roll housing 11 is connected to a channel plate adapter 1 with a fiber discharge channel 3 . The fiber inlet channel 12 is followed by the fiber outlet channel 3 , which together form a fiber channel which guides the individual fibers from the opening roller 10 to the rotor cup 2 . In ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com