Glue-free Whole Bamboo Cutting Board

A bamboo vegetable and bamboo board technology, which is applied to household appliances, applications, kitchen utensils and other directions, can solve the problems of poor practical effect, difficulty in improving the connection strength of the panel bottom plate, affecting the range of cutting boards, etc., and achieves good use effect. , Significant compression and deformation resistance, reasonable structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

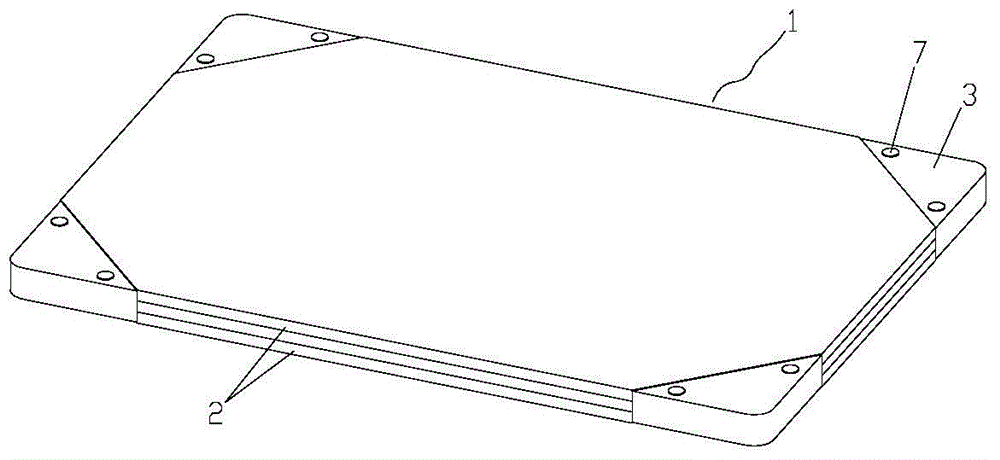

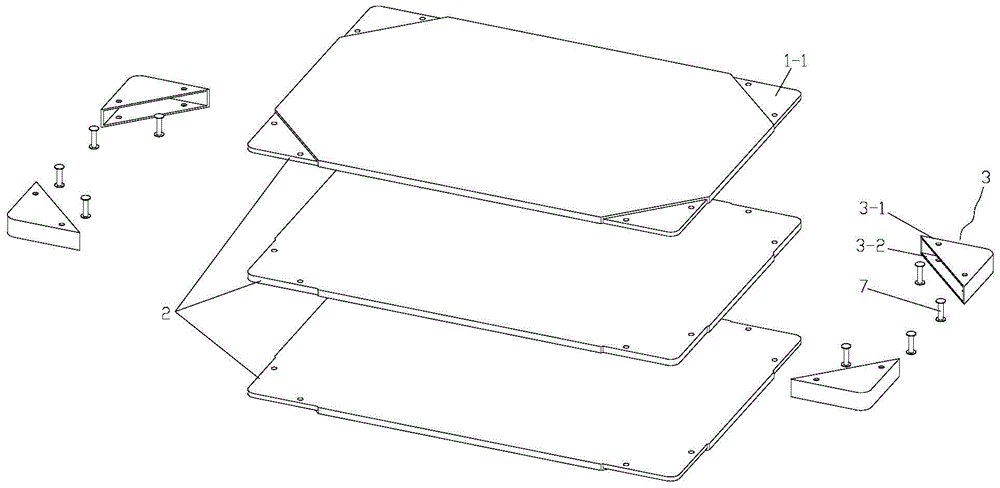

[0035] Refer to attached figure 1 , attached figure 2 And attached image 3 : this glue-free whole bamboo cutting board in the present embodiment comprises the cutting board main body 1 that at least two whole bamboo board sheets 2 are stacked together, and the side of the cutting board main body 1 is provided with one group for clamping the stationary phase The clamping part 3 of the whole bamboo plate sheet 2 is stacked.

Embodiment 2

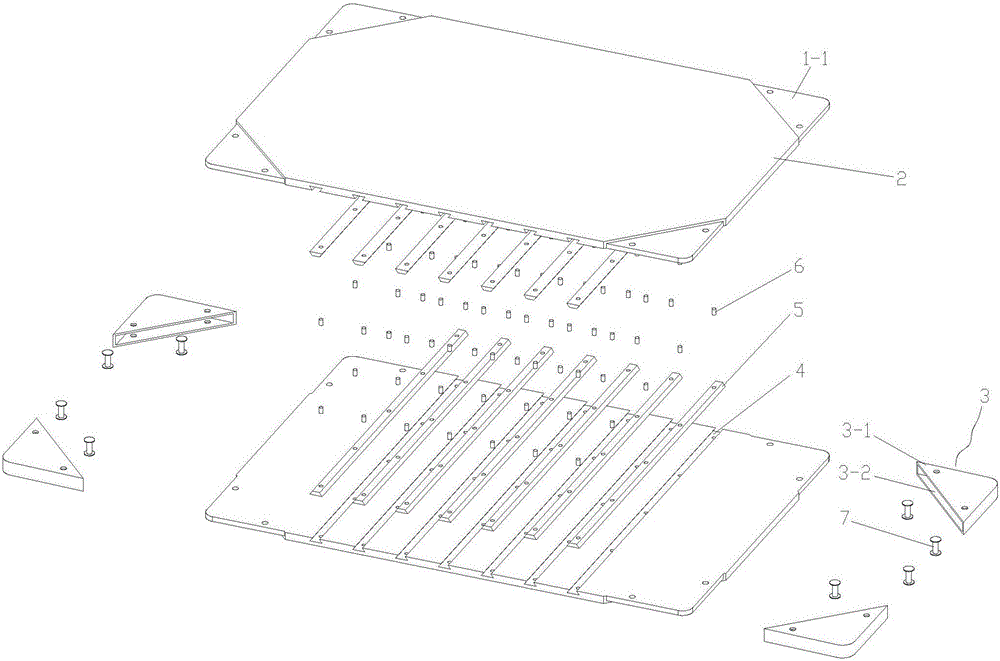

[0037] Refer to attached Figure 4 , attached Figure 5 And attached Image 6 : this non-adhesive whole bamboo cutting board in the present embodiment, the cutting board main body 1 that at least two whole bamboo board sheets 2 are stacked together, the side of cutting board main body 1 is provided with one group for clamping and fixing The holder 3 of the whole bamboo plate 2. A group of mortises 4 intersecting the fiber direction of the whole bamboo slats are arranged on the whole bamboo slab 2, and mortise blocks 5 are all installed in the mortises 4 of this group. The tongue and groove 4 are respectively arranged on the adjacent surfaces of the adjacent whole bamboo boards 2 . The tenon block 5 and the whole bamboo plate 2 are mutually fixed by bamboo nails 6 .

Embodiment 3

[0039] Refer to attached Figure 7 , attached Figure 8 And attached Figure 9 : this glue-free whole bamboo cutting board in the present embodiment comprises the cutting board main body 1 that at least two whole bamboo board sheets 2 are stacked together, and the side of the cutting board main body 1 is provided with one group for clamping the stationary phase The clamping part 3 of the whole bamboo plate sheet 2 is stacked. A group of mortises 4 intersecting the fiber direction of the whole bamboo slats are arranged on the whole bamboo slab 2, and mortise blocks 5 are all installed in the mortises 4 of this group. The tongue and groove 4 are respectively arranged on the adjacent surfaces of the adjacent whole bamboo boards 2 . The tenon block 5 and the whole bamboo plate 2 are mutually fixed by bamboo nails 6 . The adjacent whole bamboo plates 2 are mutually fixed by tenon blocks 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com