Symmetric edge-knurling roller hold-down device

A pressing device, symmetrical technology, applied in the direction of machining/deformation to achieve the effect of prolonging service life, ensuring quality and eliminating abnormal wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

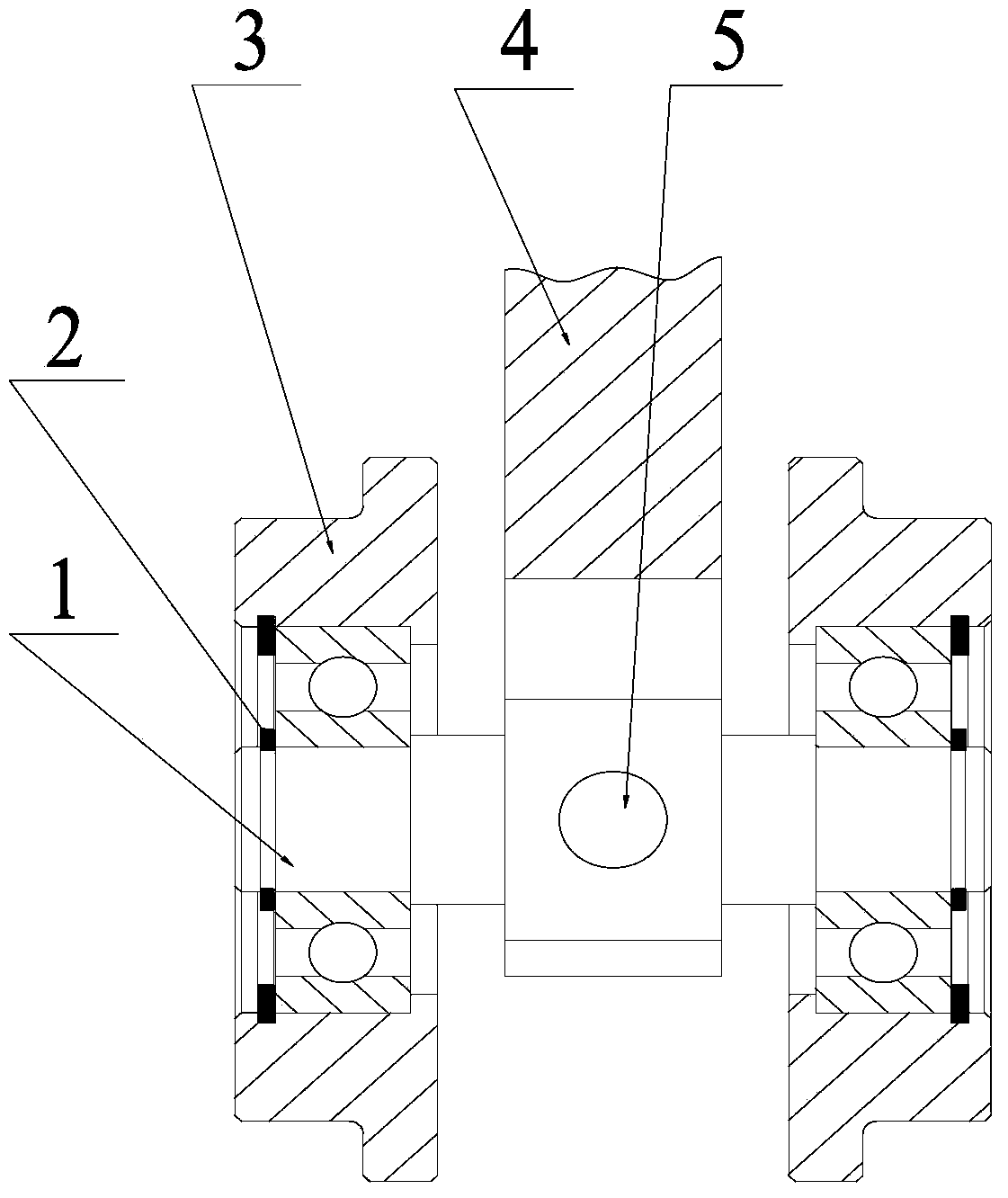

[0019] A symmetrical side embossing wheel pressing device, its structure is as follows figure 1 As shown, the device includes a side embossing wheel shaft 1, a shaft retaining ring 2, a side embossing wheel 3, a depressing guide post 4, and a pin shaft 5.

[0020] Side embossing wheel shafts 1 are arranged on both sides of the lower part of the depressing guide post 4, and the side embossing wheel shafts 1 are connected to the pressing down guide posts through pin shafts 5, and side embossing wheels 3 are sheathed on the side embossing wheel shafts 1. , the warp shaft is fixed on the side embossing wheel shaft 1 with the spring retaining ring 2, so that the side embossing wheel 3 is symmetrically arranged on both sides of the depressing guide post 4, and evenly distributes the pressure generated when the depressing guide post 4 is pressed down.

[0021] Working principle: Install two side embossing wheels 3 face-to-face symmetrically on both ends of the side embossing wheel sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com