Cap-shaped steel plate pile

A steel sheet pile and hat-shaped technology, which is applied to sheet pile walls, buildings, and foundation structure engineering, can solve problems such as reduced construction efficiency, local bending, and increased penetration resistance, so as to suppress bending/deformation, ensure stability, The effect of improving constructability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

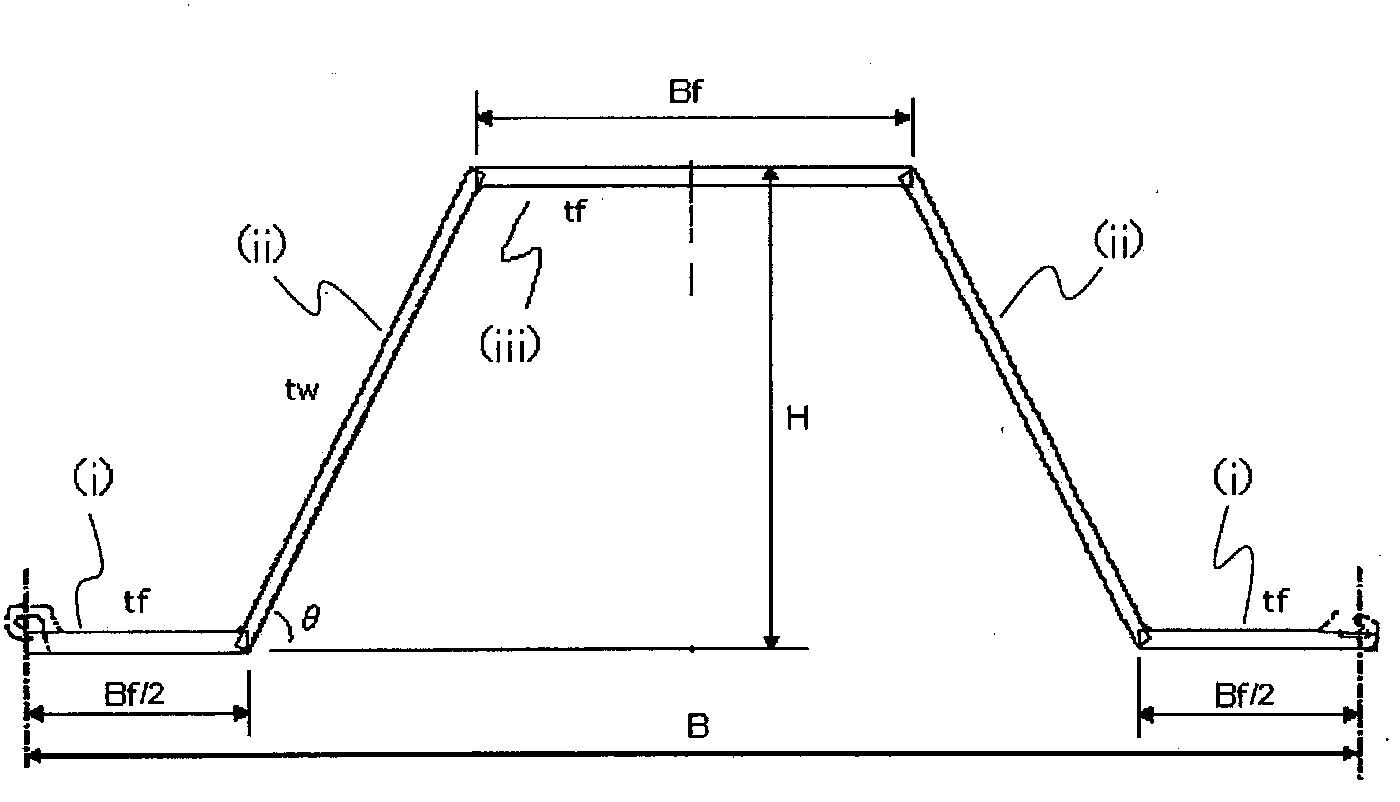

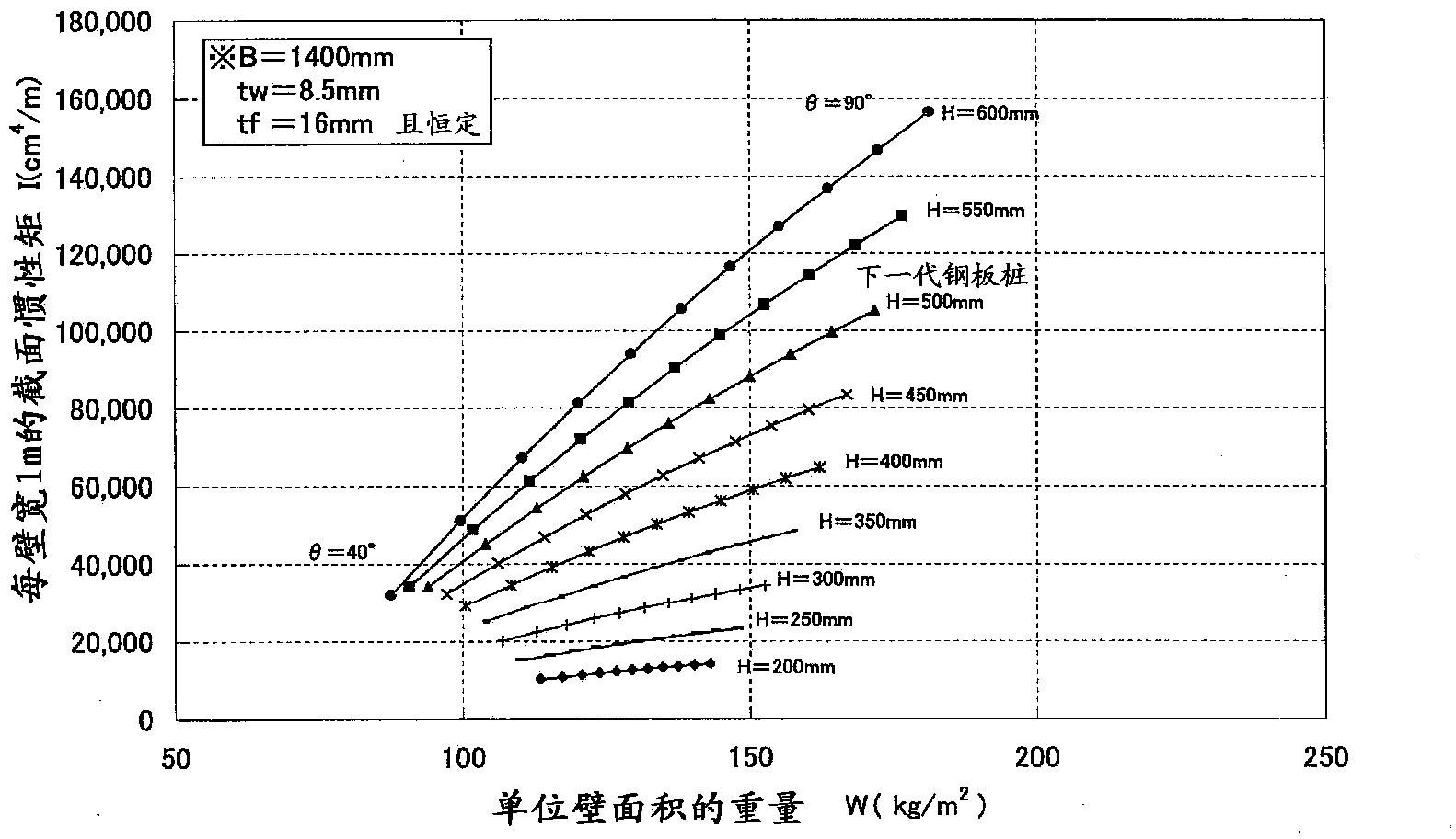

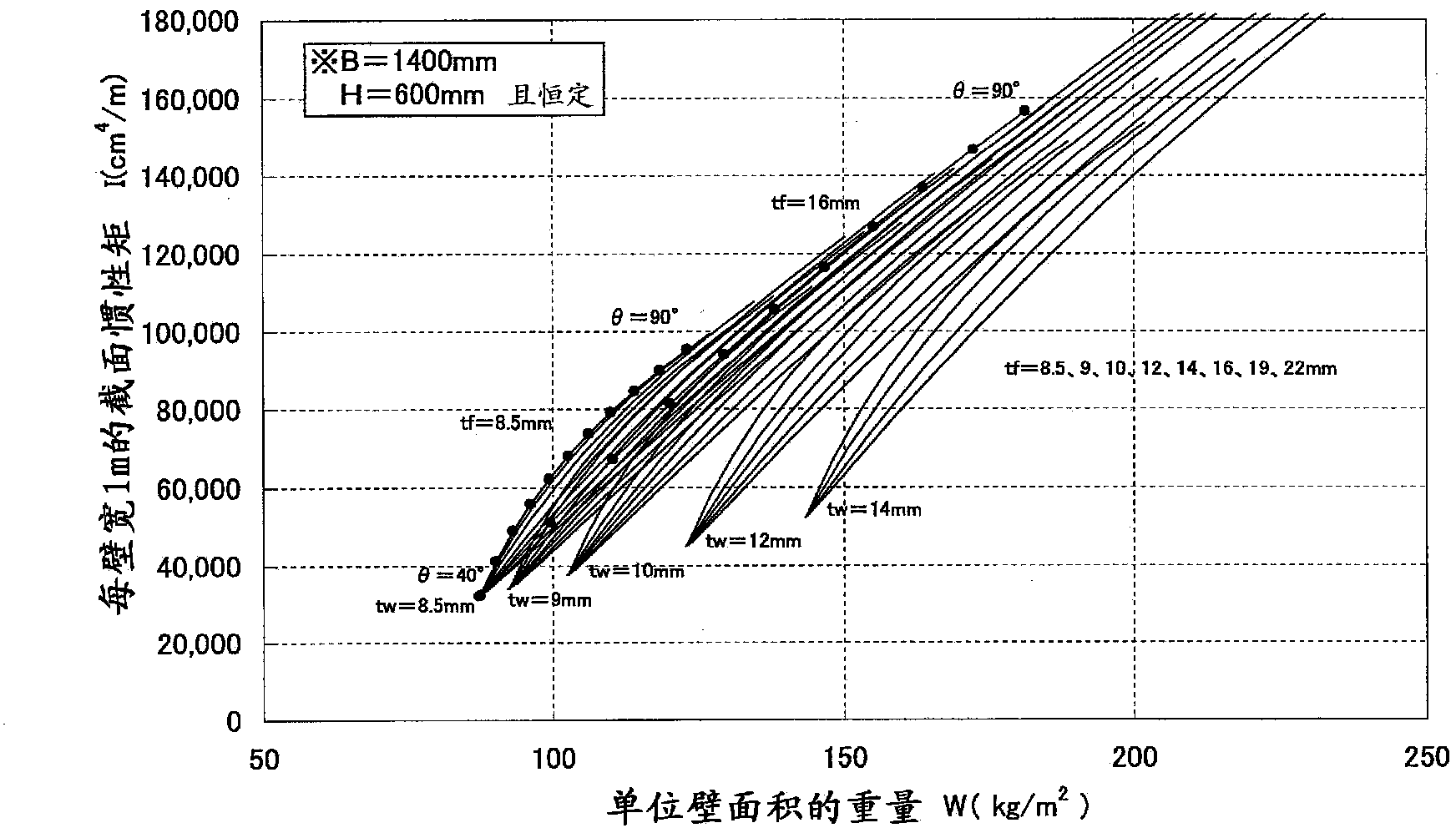

[0167] As an example of the present invention, hat-shaped steel sheet piles of the specifications shown below were designed.

[0168] B=1400mm, H=540mm, θ=75°, I=114810cm 4 / m

[0169] Check whether the hat-shaped steel sheet piles of the above specifications are within the range of the above indicators.

[0170] Bringing the specifications of the above-mentioned hat-shaped steel sheet piles into the formula (4) and the formula group (C), the results are as follows.

[0171] (4) Formula: 2.65×10 -4 ×I+22≤θ≤80(20000≤I<200000)

[0172] 2.65×10 -4 ×I+22=2.65×10 -4 ×114810+22=52.4

[0173] 52.4<θ=75<80, θ is within the range of formula (4).

[0174] In the case of formula group (B): 67<θ≤80 (80000≤I<200000), θ=75° of the hat-shaped steel sheet pile satisfies 67<θ=75<80, that is, formula group (B).

[0175] Therefore, it turns out that the hat-shaped steel sheet pile of this Example mentioned above is excellent in economical efficiency and workability, and also is more exce...

Embodiment 2

[0177] As an example of the present invention, hat-shaped steel sheet piles of the specifications shown below were devised.

[0178] B=1400mm, H=540mm, θ=75°, I=81454cm 4 / m

[0179] Bringing the specifications of the above-mentioned hat-shaped steel sheet piles into the formula (4) and the formula group (B), the results are as follows.

[0180] (4) Formula: 2.65×10 -4 ×I+22≤θ≤80(20000≤I<200000)

[0181] 2.65×10 -4 ×I+22=2.65×10 -4 ×81454+22=43.6.

[0182] 43.6<θ=75<80, θ is within the range of formula (4).

[0183] When formula group (B): 67<θ≤80 (80000≤I<200000), θ=75° of the hat-shaped steel sheet pile satisfies 67<θ=75<80, that is, formula group (B).

[0184] Therefore, it turns out that the hat-shaped steel sheet pile of this Example mentioned above is excellent in economical efficiency and workability, and also is more excellent in economical efficiency.

[0185] In addition, in the above description, although the multiplication of the economic index and the cons...

Embodiment 3

[0190] As a research example on the setting method of the constructability index R of the present invention, a steel sheet pile model (length 100 cm) with a scale of 1 / 12 was pressed into a foundation made of No. 5 silica sand at a constant speed. Examples of construction tests of driven models.

[0191] Regarding the implementation examples of the model construction test, Table 3 shows the shape converted into the actual size, the economic index 1 / W and the constructability index R determined based on the shape. In addition, the shape of the sample is set such that the section moment of inertia I per 1 m of the sample is about 55000 (cm 4 / m).

[0192] Table 4

[0193] Implementation examples of model construction tests

[0194]

[0195] Table 5 compares the value of the penetration resistance (maximum load) P during construction and the normalized P / P45° of the penetration resistance (maximum load) P45° of the utilization case (2) (θ=45°), and the constructability inde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com