An inverted track sliding system and sliding method thereof

An inverted track technology, applied in the direction of track, movable track, road, etc., can solve the problems that the track cannot be completely laid, and the overall slip cannot be realized, so as to achieve the effect of two-way slip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

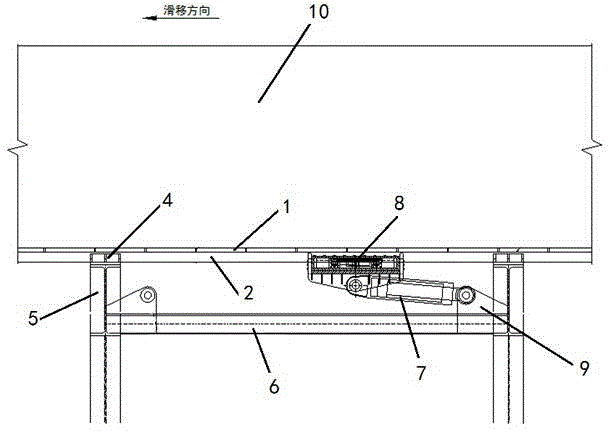

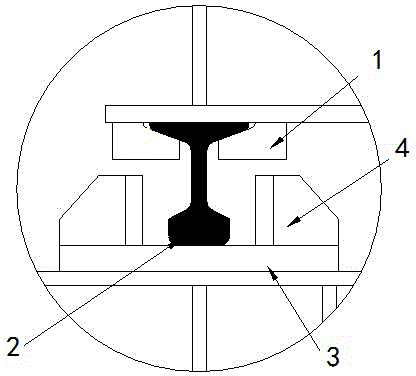

[0021] An inverted rail sliding system as shown in the figure includes: rail pressing plate 1, moving rail 2, sliding block 3, support frame 5, fixed base 6, crawler 7, rail clamp 8, connecting lug plate 9.

[0022] The connection relationship of the above components is as follows:

[0023] There are at least two support frames 5; the fixed base 6 is fixed between two adjacent support frames;

[0024] The slide block 3 is located on the top of the support frame 5, and the upper surface of the slide block 3 is provided with a sliding guide groove 4; the track pressing plate 1 is installed under the sliding box 10; the track pressing plate 1 buckles the moving rail 2 The upper end is fixedly connected to it; the lower end of the movable rail 2 is located in the guide groove 4 to support the sliding box 10; one end of the crawler 7 is fixed on the fixed base 6, and the other end is connected to the rail clamp 8 The bottom end is connected, the upper end of the rail clamp 8 clamps the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap