A Two-way Sliding Pipe Support Capable of Bearing Two-way Vertical Loads

A pipe support and vertical load technology, applied in the direction of pipe supports, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of low friction coefficient and failure to meet the requirements of use, and achieve the effect of two-way sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

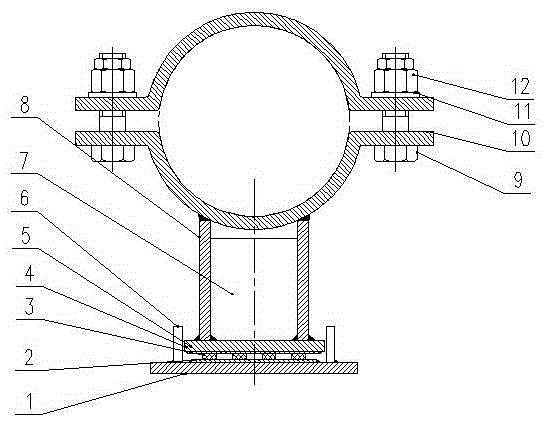

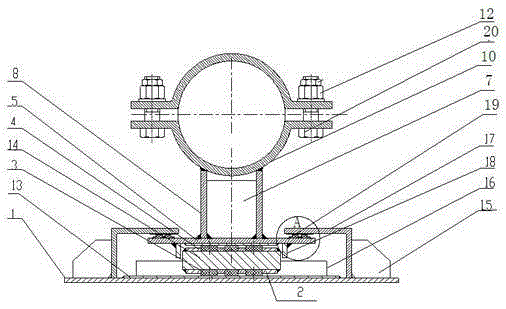

[0017] The present invention is described in conjunction with accompanying drawing and specific embodiment:

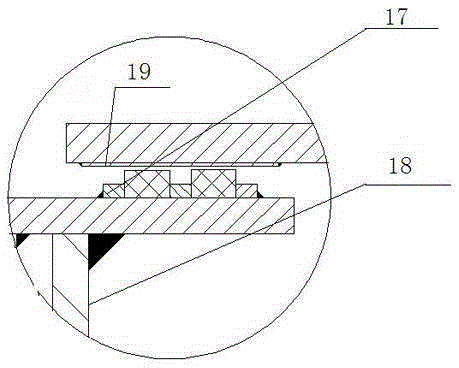

[0018] Such as figure 2 , image 3 As shown, a two-way sliding pipe support that can withstand two-way vertical loads; the two-way sliding pipe support includes a lower base plate 1 and an upper base plate 5; the upper base plate 5 is located above the lower base plate 1, on the upper A pipe is installed above the base plate 5, that is, the pipe is clamped by two half-type pipe clamps 10, and the pipe clamp 10 is fixed on the upper base plate 5 through the vertical plate 7; between the upper base plate 5 and the lower base plate 1 An intermediate plate 14 is provided; the upper and lower surfaces of the intermediate plate 14 are fixed with an orifice 2 for installing a polytetrafluoro slide 3; the polytetrafluoro slide 3 is installed in the orifice; located in the middle The sliding friction pair I is formed between the PTFE sliding plate 3 on the upper surface of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap