Refrigerator and control method thereof, ice making assembly of refrigerator and control methods thereof

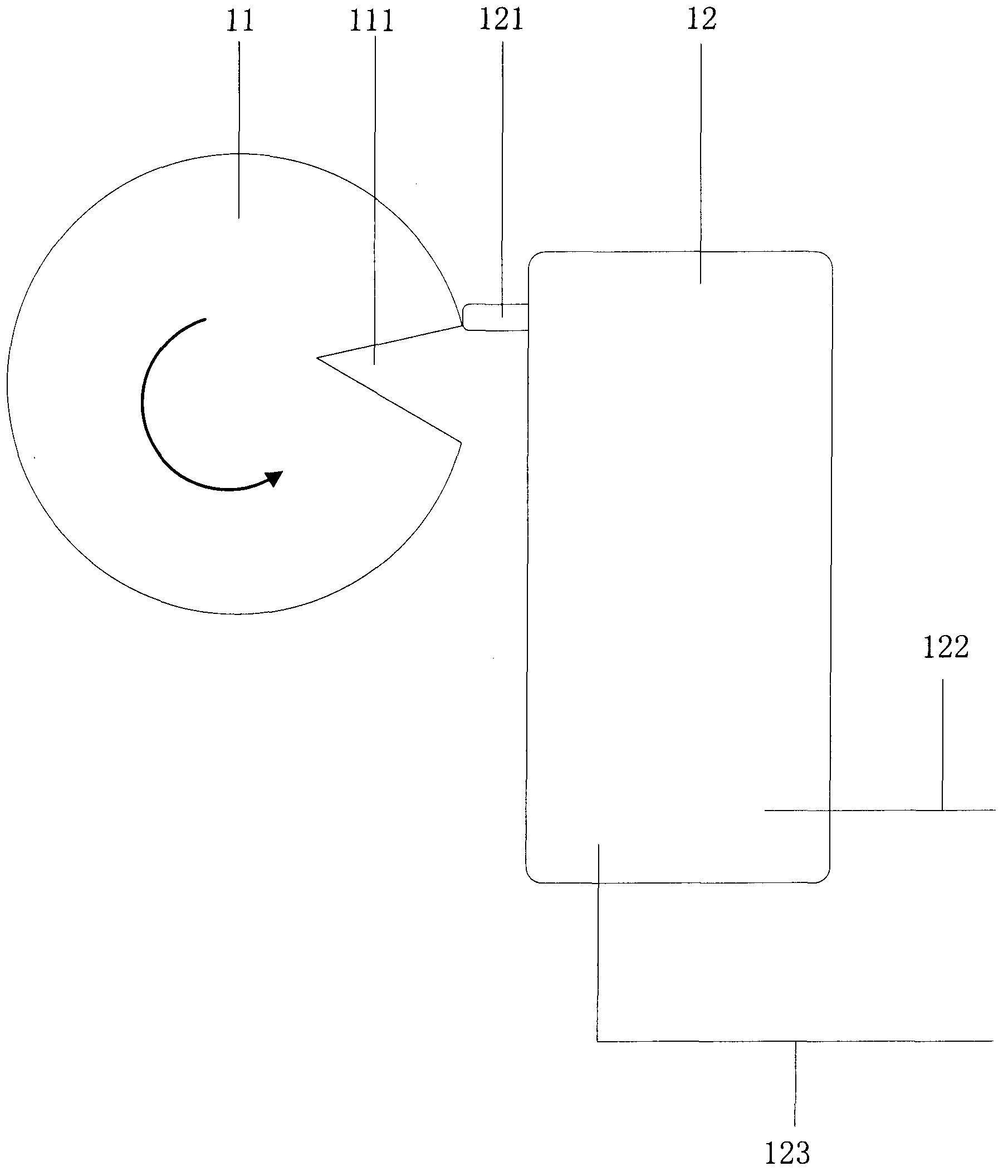

A control method and technology of components, which are applied in the directions of ice making, ice making, and household refrigeration devices, etc., can solve the problems of poor contact between the protrusion 121 and the cam 11, different water supply time, and different water supply time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

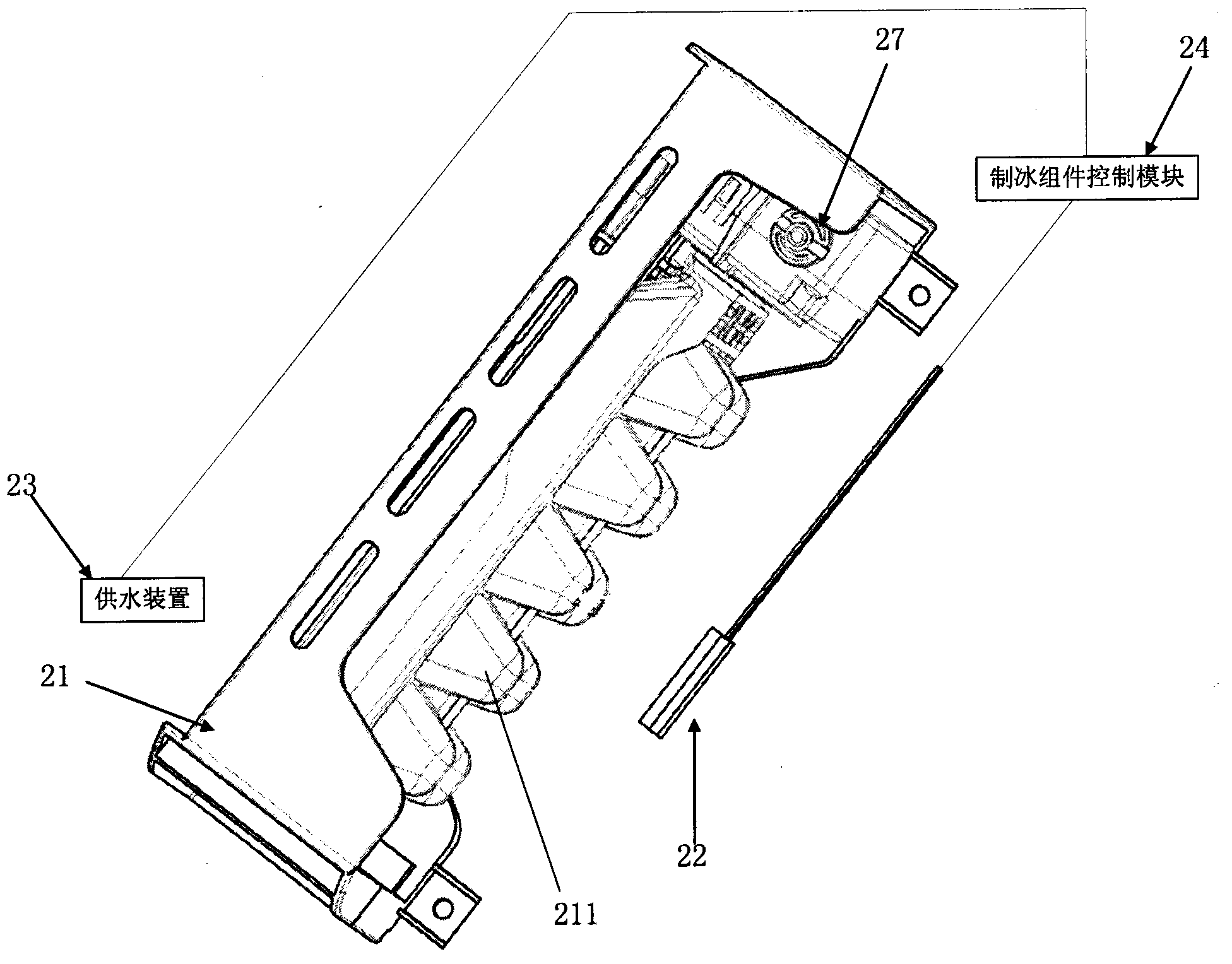

[0072] As mentioned above, the present invention adopts a pressure sensor arranged at the bottom of the tray to provide accurate ice-making amount by measuring the weight of the water in the tray. And the number of pressure sensors can be one or more. Combine the following Figure 2 to Figure 9 , taking setting up a pressure sensor as an example, the technical solution of the present invention is introduced in detail.

[0073] First refer to figure 2 As shown, the ice making assembly of the refrigerator includes:

[0074] the tray 21, including at least one ice slot 211;

[0075] The pressure sensor 22 is arranged at the bottom of the tray 21 for measuring the weight of the water in the tray 21;

[0076] The water supply device 23 is used to supply water to the ice tank 211 of the tray 21;

[0077] The ice making assembly control module 24 is connected with the water supply device 23 and the pressure sensor 22 respectively, and controls the opening and closing of the wat...

Embodiment 2

[0098] It can be understood that when a pressure sensor 22 is used in the first embodiment, complex experiments are required to make a table in order to solve whether it is placed at the bottom of the tray 21 at the end close to the water inlet or at the end far away from the water inlet. In order to solve this problem, two pressure sensors 22 are used in the second embodiment, and the positions of the pressure sensors 22 are not limited, and they can be located at the bottom of the tray 21 .

[0099] Correspondingly, as Figure 10 As shown, the ice making assembly includes a central processing unit 26 for converting the weight of the water in the tray 21 measured by at least two pressure sensors 22 into an average value of the weight of the water in the tray 21 . In addition, the ice-making assembly further includes a second comparison module 244, which is connected to the central processing unit 26 and the information storage module 241 respectively, and is used to compare w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com