Method for manufacturing electrochemical battery

A manufacturing method and electrochemical technology, applied in the direction of electrochemical generators, secondary batteries, final product manufacturing, etc., can solve the problem of battery storage energy reduction and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

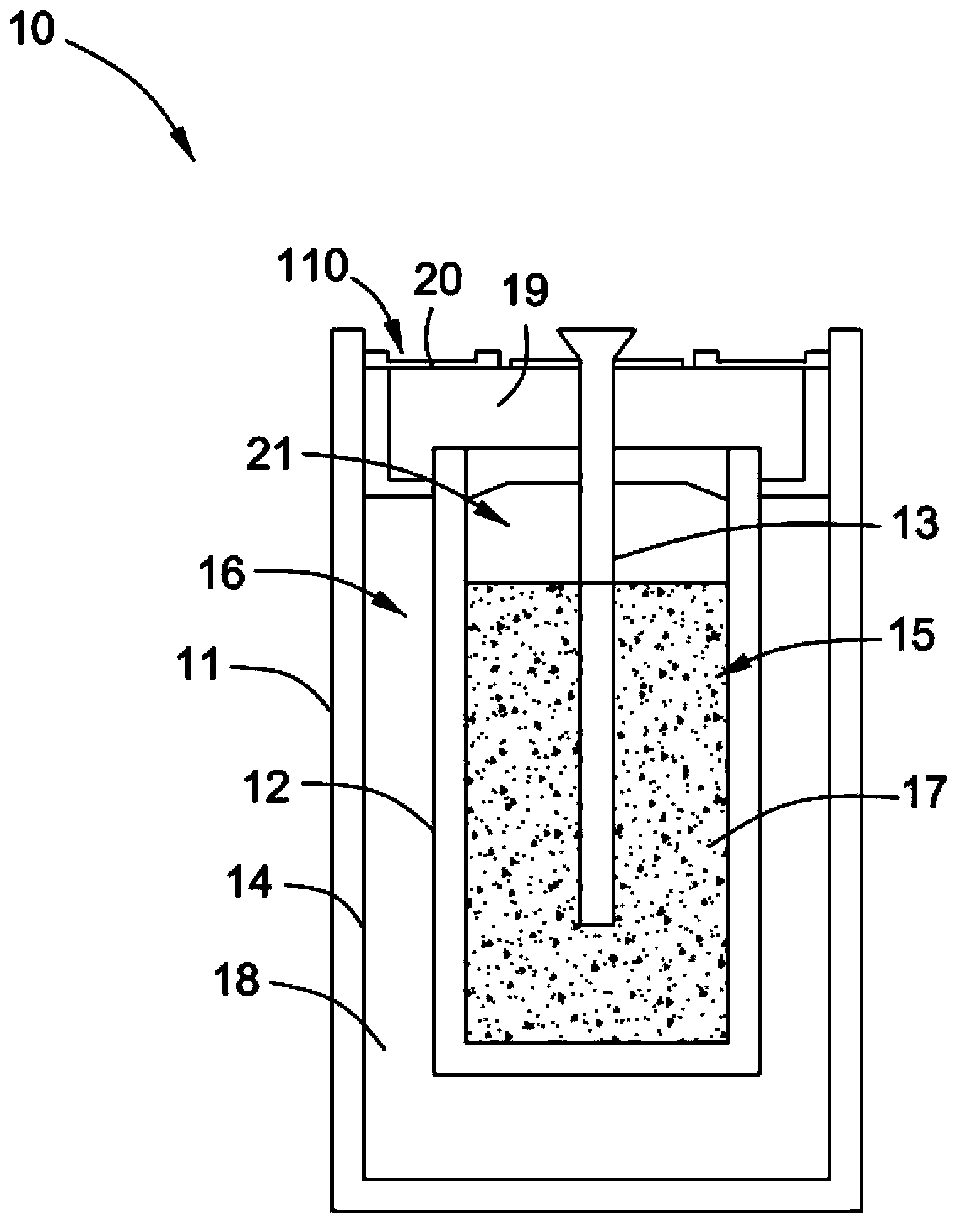

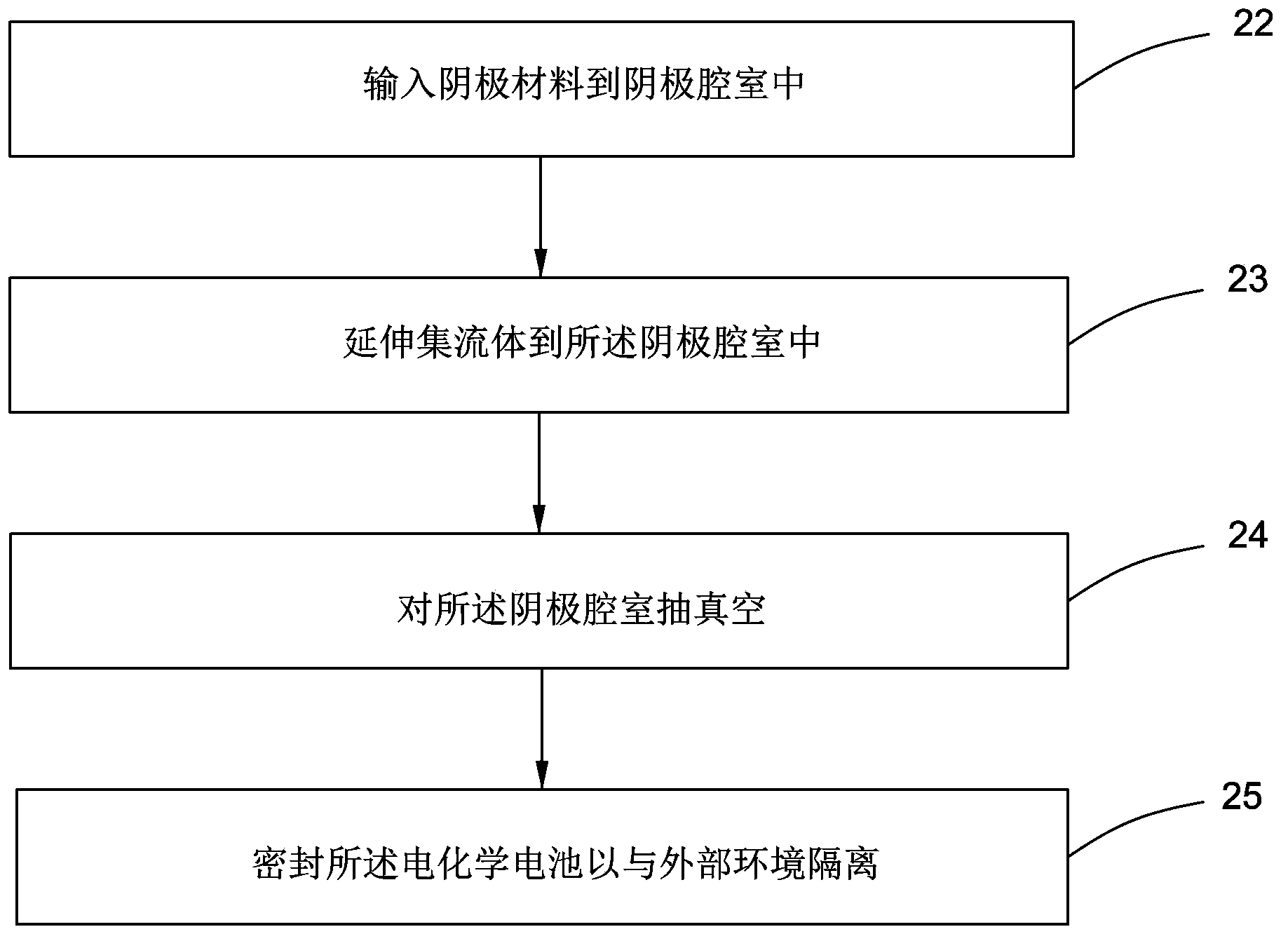

[0012] One embodiment of the invention provides a method of making an electrochemical cell. The method includes introducing a cathode material into a cathode chamber of the electrochemical cell while the electrochemical cell is in a ground state; evacuating the cathode chamber and sealing the electrochemical cell from the external environment. Wherein the electrochemical cell further includes an anode chamber separated from the cathode chamber by its solid electrolyte and in ionic communication with the cathode chamber.

[0013] In one embodiment, the solid electrolyte defines a cathode compartment; the anode compartment is defined between the solid electrolyte and the housing of the electrochemical cell. In another embodiment, the solid electrolyte defines an anode compartment; the cathode compartment is defined between the solid electrolyte and the housing of the electrochemical cell.

[0014] figure 1 Shown is a schematic diagram of one embodiment of an electrochemical ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com