Ethylene-based polymer, polyethylene-based resin composition and use thereof, catalyst component for olefin polymerization, catalyst for olefin polymerization comprising the same, and method for producing an ethylene-based polymer using the catalyst

A resin composition, polyethylene technology, applied in the field of new polyethylene resin composition, production of olefin polymers, molded products and films, can solve the problem of few double bonds, short branch length, and unpredictable improvement in molding processing Sexual effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0137] Sample preparation: A solution of 1 mg / mL sample was prepared using ODCB (containing 0.5 mg / mL BHT) and dissolved at 140° C. for about 1 hour.

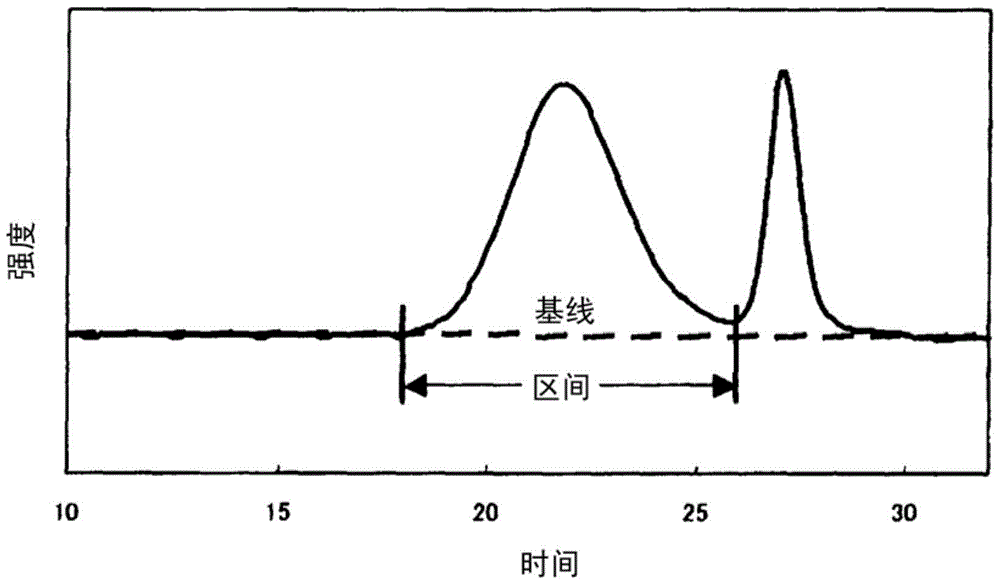

[0138] By the way, for example, such as figure 1 The baseline and interval of the chromatogram obtained by the measurement shown.

[0139] 1-4. Conditions (A-4)

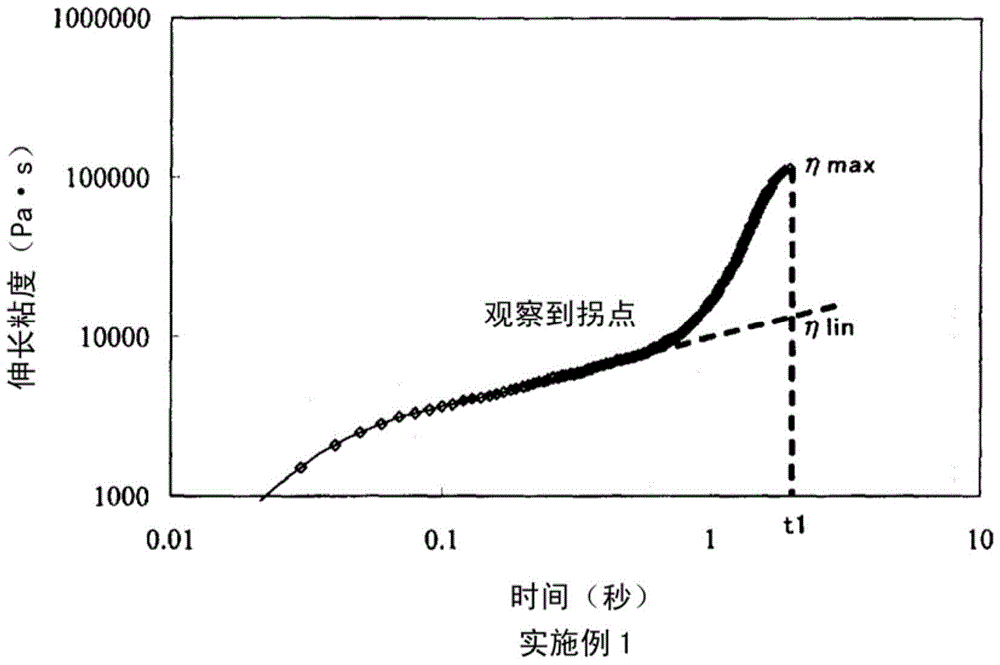

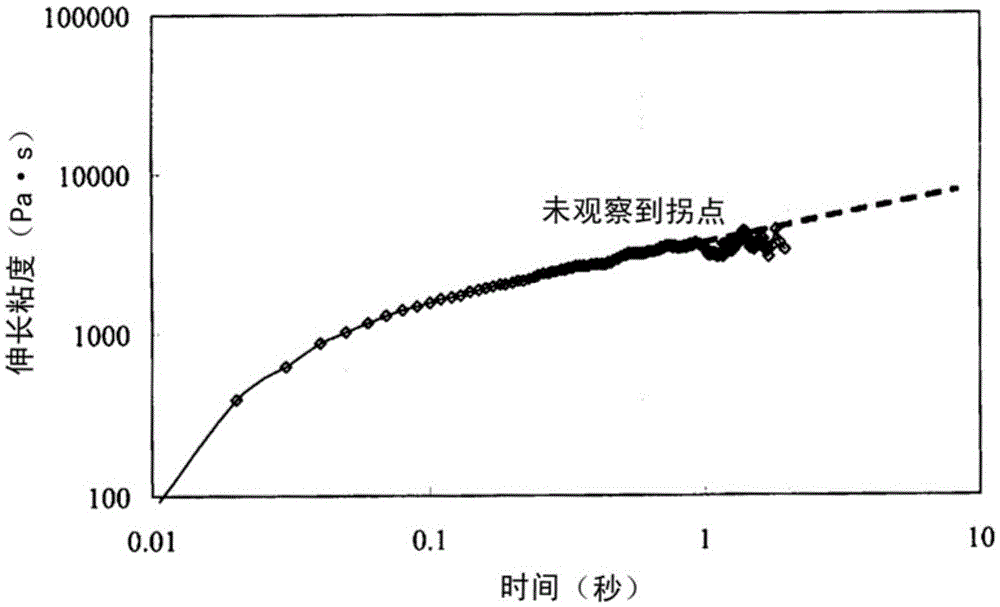

[0140] The component (A) in the present invention satisfies the following conditions: elongational viscosity η(t) (unit: Pa·sec) and elongation time measured at a temperature of 170°C and an elongation strain rate of 2 (unit: 1 / sec) In the logarithmic graph of t (unit: second), no inflection point of elongational viscosity attributable to strain hardening is observed or when an inflection point is observed, the maximum elongational viscosity after strain hardening is assumed to be η Max (t 1 ) And the approximate straight line of the elongational viscosity before curing is η Linear (t), then by η Max (t 1 ) / η Linear (t 1 ) Defined strain hardening degree [λmax(2.0)] A 1...

Embodiment 1a

[0950] (1) Production of ethylene polymers (A-1)

[0951] [Preparation of metallocene catalyst A-1]

[0952] In a catalyst preparation device equipped with an electromagnetic induction stirrer, under nitrogen flow, add 1,000ml of pure toluene, 22g of tetraethoxyzirconium (Zr(OEt) 4 ), 75 g of indene and 88 g of methyl butyl cyclopentadiene while maintaining the system at 90° C., 100 g of tripropyl aluminum was added dropwise over 100 minutes, and then reacted at the same temperature for 2 hours. After cooling the reaction product to 40°C, 3,200 ml of a toluene solution of methylaluminoxane (concentration: 2.5 mmol / ml) was added. After stirring for 2 hours, 2,000 g of silica (#952, produced by Grace, surface area: 300 m2 / g) that was calcined at 450°C for 5 hours in advance was added and stirred at room temperature for 1 hour. After that, nitrogen blowing and drying under reduced pressure at 40°C were performed to obtain a solid catalyst A-1 having good fluidity.

[0953] [Production...

Embodiment 2a

[0975] Except in Example 1a(c), a commercially available ethylene polymer (A-2) (UF230, produced by Japan Polyethylene Corporation) produced using a magnesium-titanium composite Ziegler catalyst (A-2) was used ; MFR=1.0g / 10min, density: 0.921g / cm 3 , Ethylene 1-butene copolymer) instead of the ethylene polymer (A-1) produced by the metallocene catalyst, the polyethylene resin composition 2 was processed in the same manner as in Example 1a(c) Production and film forming. The results obtained are shown in Table 1a-1 and Table 1a-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com