Portable safety cart

A small trolley and portable technology, which is applied to trolleys, single-axis trolleys, motor vehicles, etc., can solve the problems of increased secondary handling costs, high maintenance costs, and material slippage, so as to reduce secondary handling costs and increase safety coefficient, the effect of reducing the maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

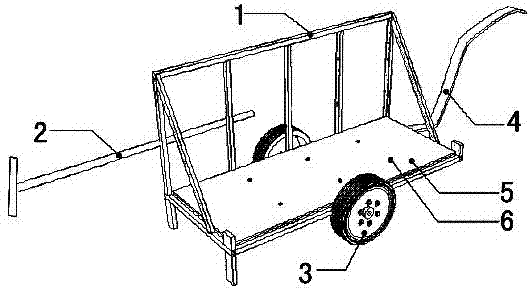

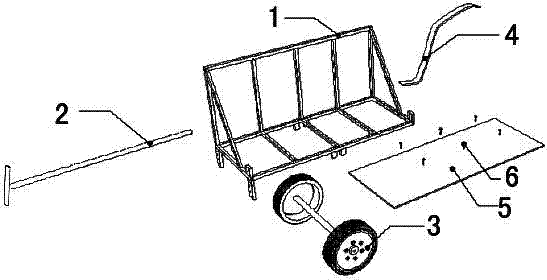

[0020] Example: such as figure 1 , figure 2 As shown, a portable safety trolley includes a vehicle frame 1, a handle 2, and a bearing wheel set 3.

[0021] The bearing wheel set 3 is installed at the bottom of the vehicle body, and the handle 2 is fixed on the vehicle body. Frame 1 is an "L"-shaped frame. Frame 1 is a frame assembled from square tubes, which is welded by multiple 40*20*4mm square tubes. This shape is convenient for sheet materials to be placed or carried on the side. And move down the trolley. The bottom edge of the frame 1 is provided with a blocking structure that prevents the plate from slipping. The blocking structure is a square tube that is welded at the bottom edge of the frame 1 and is higher than the frame of the frame 1. The oblique square tube is designed as a front and rear limit for the plate. Prevent materials from slipping and falling during transportation. An oblique supporting piece is provided at the front and rear ends of the edge of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com