Horizontal elastic limiting and longitudinal hydraulic fusing damping combined support system

An elastic limit and hydraulic technology, applied in the direction of bridge parts, bridges, buildings, etc., can solve the problems of bearing damage to the bridge deck and track displacement, difficult maintenance and high cost, and achieve the effect of improving earthquake strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

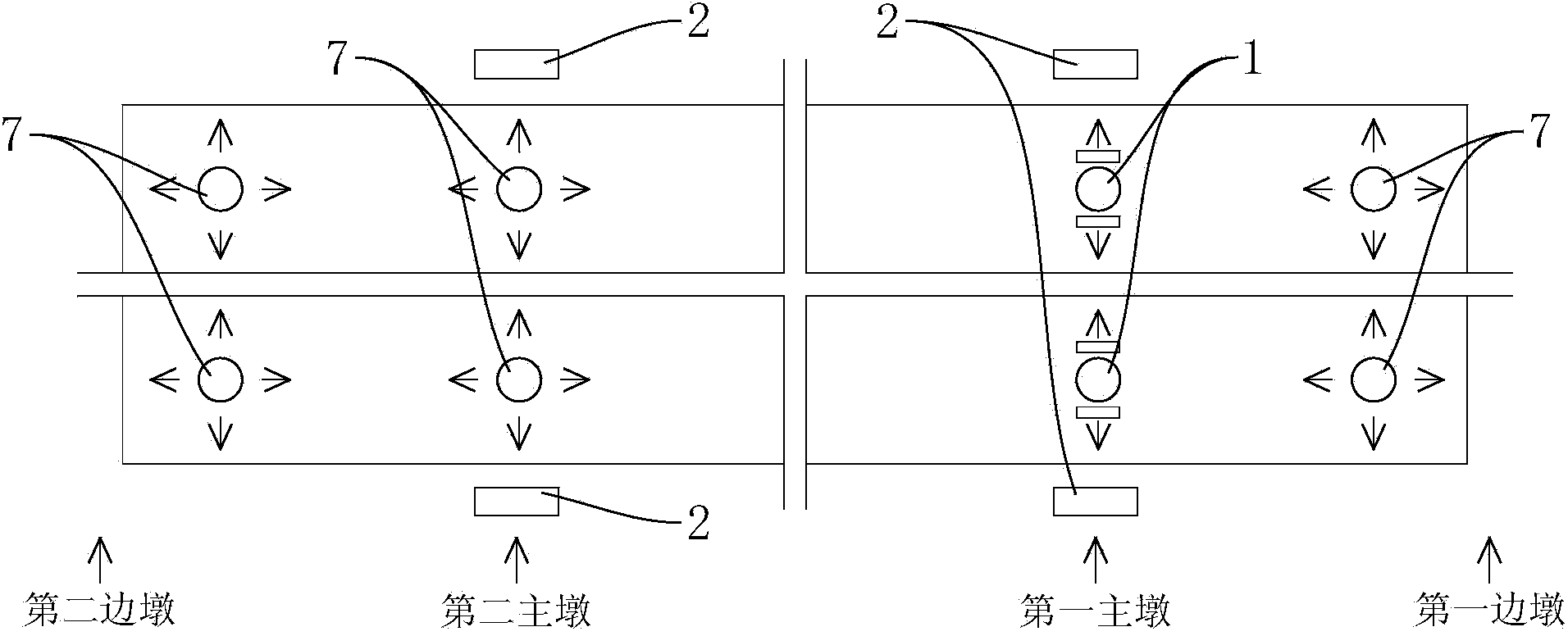

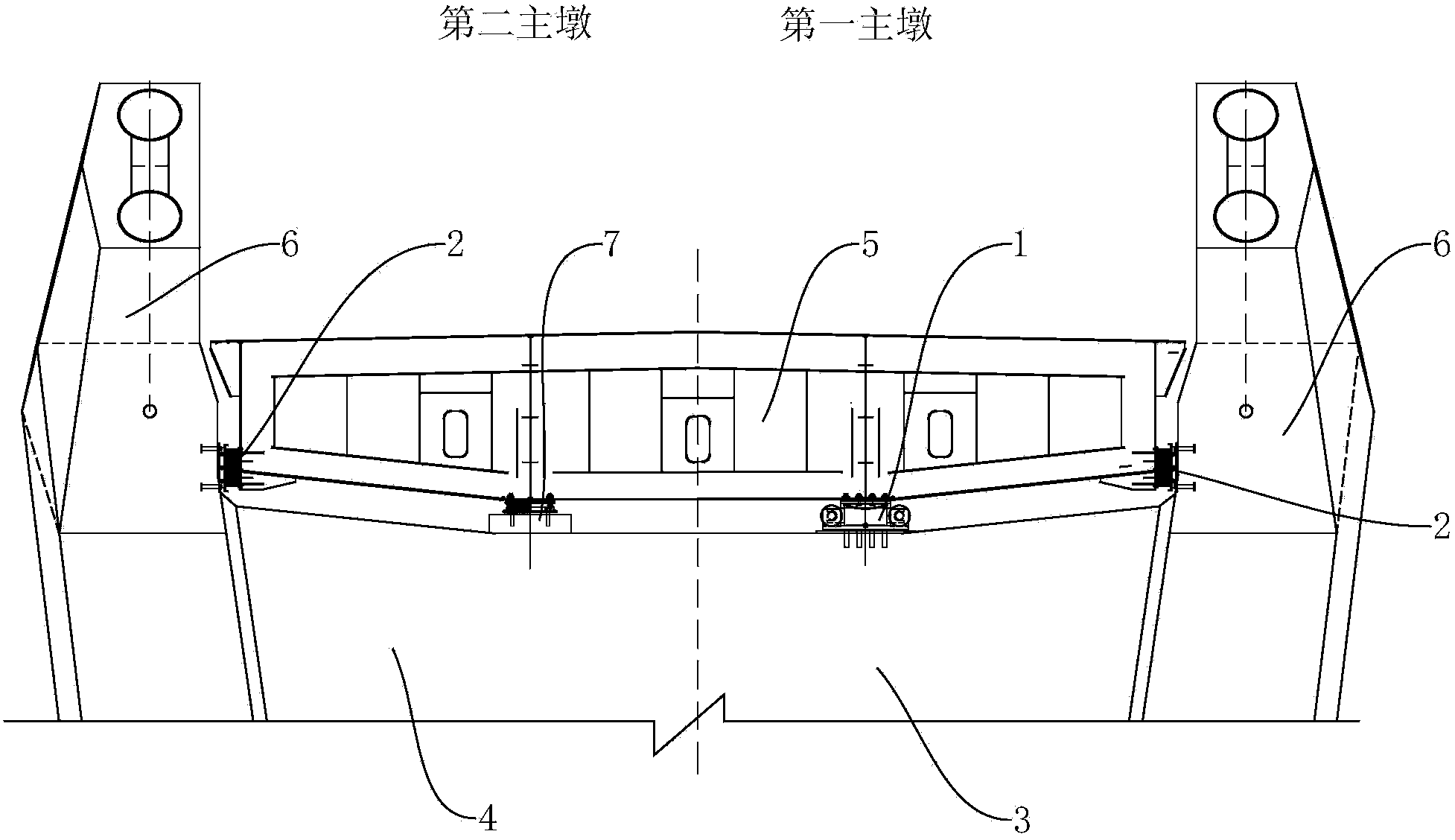

[0030] Such as figure 1 and figure 2 As shown, the combined support system of transverse elastic limit and longitudinal hydraulic fuse damping adopts hydraulic fuse damping support 1 for longitudinal restraint and limit height adjustment rubber support 2 for lateral restraint; the hydraulic fuse damping support 1 is located at the same span Between the top of the first main pier 3 on the side and the bottom of the main beam 5; the height-limiting rubber bearing 2 is located between the inner side of the arch foot 6 and the outer side of the main beam 5; the second main pier opposite to the first main pier 3 The pier 4 is provided with a two-way movable spherical steel support 7; preferably, both the first side pier and the second side pier adopt a two-way movable spherical steel support 7.

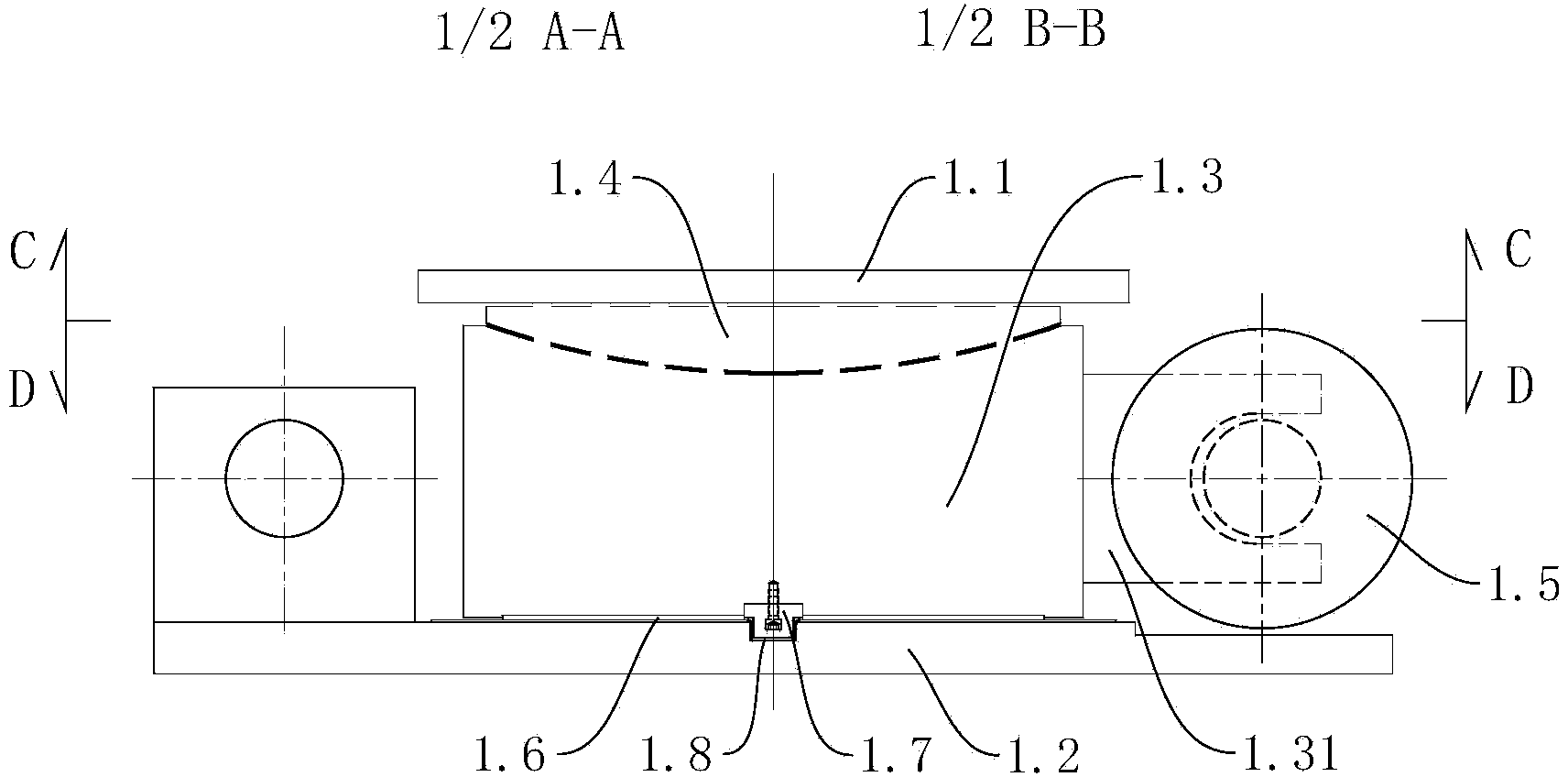

[0031] Such as image 3 and Figure 4 As shown, the hydraulic fuse damping support 1 includes an upper support plate 1.1 and a lower support plate 1.2; a heightening block 1.3 is slida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com