Ultra-precision air static pressure connecting joint device

An aerostatic, ultra-precision technology, applied in couplings, elastic couplings, mechanical equipment, etc., can solve problems such as lateral force, tilt, vibration, etc., to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

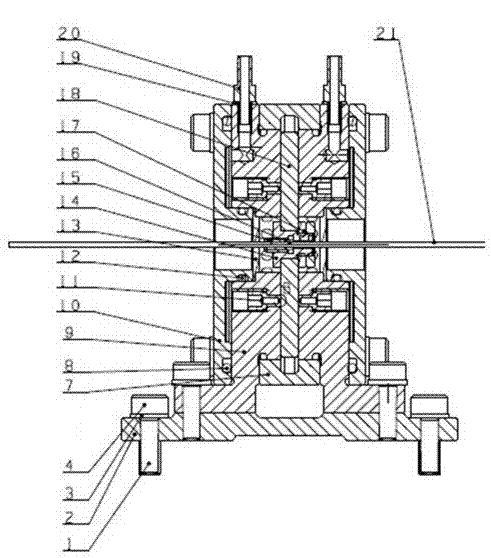

[0016] The present invention will be described in detail below with reference to the drawings of the sealing disk and in combination with embodiments.

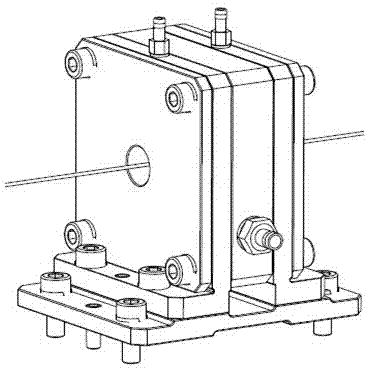

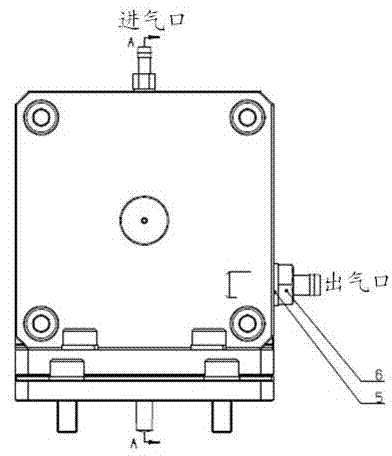

[0017] refer to figure 1 , figure 2 , image 3 As shown, an ultra-precision aerostatic coupling device includes a mounting base plate 2 and a drawing wire 21, the drawing wire 21 is fixedly connected with the drawing wire fixed steel ball 16, and the drawing wire fixing steel ball 16 is loaded into a steel ball The positioning sleeve 14 is used to position and lock the traction steel wire fixed steel ball 16 through the steel ball locking screw 15. The steel ball positioning sleeve 14 is coaxially positioned and installed with the aerostatic thrust plate 18, and is pressed by the lock nut 17. Tightly locked, the left and right two air static pressure support plates 9 are sleeved on the traction steel wire 21, and the air static pressure support plates 9 are coaxially fixed and installed by the sealing disc 7 to form an air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com