Magnetic toner

A toner and magnetic technology, applied in the field of magnetic toners, can solve the problems of changes in chargeability and fluidity, inability to control toner concentration, and reduction in image density, and achieve good chargeability and fluidity, and excellent image quality. Reproducible, high image density effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

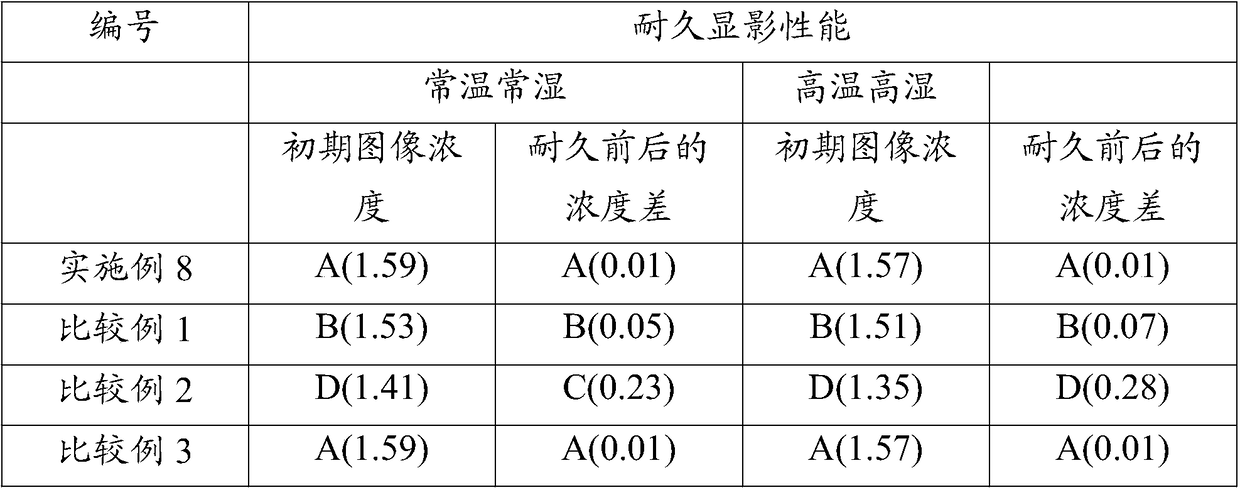

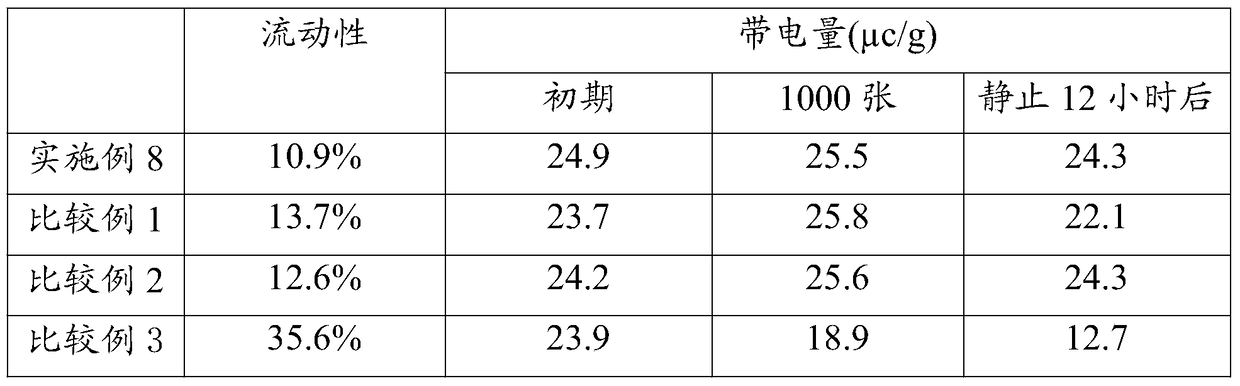

Examples

Embodiment 1

[0119] Example 1 Preparation of Magnetic Iron Oxide

[0120] The aqueous solution of ferrous sulfate was mixed with 1.0 equivalent of caustic soda solution with respect to the iron element and 1.5% by mass of sodium silicate (sodasilicate) in terms of silicon element with respect to the iron element. Thus, an aqueous solution containing ferrous hydroxide was prepared. While the pH of the aqueous solution was kept at 9.0, air was blown into the solution so that the oxidation reaction could proceed at 80°C or higher to 90°C or lower. Thus, a slurry liquid from which seed crystals will be produced is prepared. Next, an aqueous solution of ferrous sulfate was added to the slurry liquid in an amount of 1.0 equivalent to the alkali amount (sodium component of caustic soda). Thereafter, the pH of the slurry liquid was kept at 8.0, and the oxidation reaction proceeded while air was blown into the liquid. Thus, a slurry liquid containing magnetic iron oxide was obtained. The slurry...

Embodiment 2

[0121] The preparation of embodiment 2 polyester resin

[0122] Put 40 parts by weight of PO (propylene oxide) 2 mole adducts of bisphenol A, 30 parts by weight of EO (ethylene oxide) 2 moles of adducts of bisphenol A, 25 parts by weight of terephthalic acid in the reaction tank Parts by weight, 4 parts by weight of fumaric acid, 5 parts by weight of trimellitic anhydride, and 2.5 parts by weight of dibutyltin oxide were polycondensed at 220° C. to obtain polyester binder resin 1 . The resin had an acid value of 22 mgKOH / g, a hydroxyl value of 32 mgKOH / g, a Tg of 59° C., a weight average molecular weight (Mw) of 200,000, and a THF insoluble content of 14% by weight.

Embodiment 3

[0123] Embodiment 3 Preparation of graphite sheet doped with nitrogen

[0124] Put the cleaned small quartz tube into a large quartz tube reactor, then put it into a horizontal tube furnace, raise the temperature to 575°C in a hydrogen atmosphere, then turn off the hydrogen, introduce acetylene, and maintain it at a high temperature of 575°C. Acetylene was cracked by autoclaving for 4 hours. Finally, after the system is cooled to room temperature, collect the flaky graphite flakes at the bottom of the small quartz tube; weigh 5g of the prepared graphite flakes, put them into the quartz tube, and then put them into a horizontal tube furnace. Introduce Ar gas, maintain 1 atmosphere pressure in the Ar atmosphere, raise the temperature to 600°C, then close the Ar gas, and infuse NH in the horizontal tube furnace 3 , and maintained at a temperature of 500 ° C, and maintained at 1 atmospheric pressure, annealed for 4 hours, then passed Ar into the horizontal tube furnace, kept in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com