A production process of square washer continuous mold

A production process, washer technology, applied in the field of square washer continuous mold production process, can solve the problems of increasing the difficulty of unloading, difficult product delivery, product bending and deformation, etc., to reduce the difficulty of unloading, not easy to bend and deform , The effect of easy uninstallation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

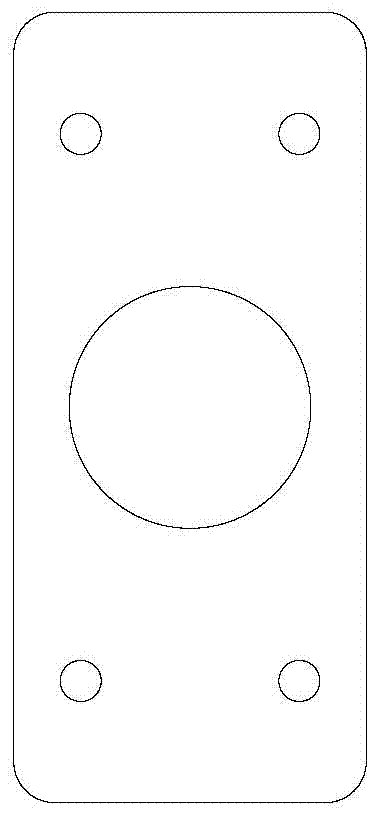

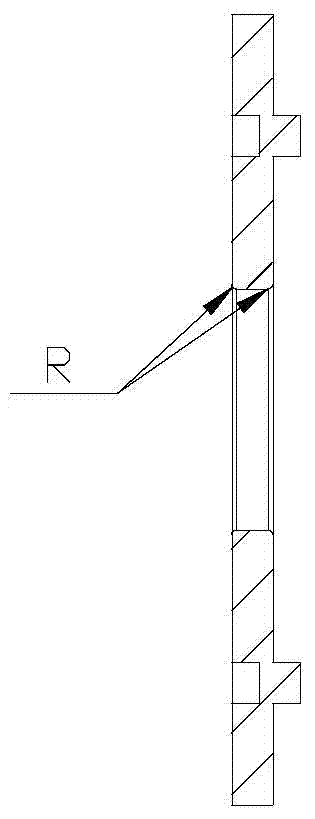

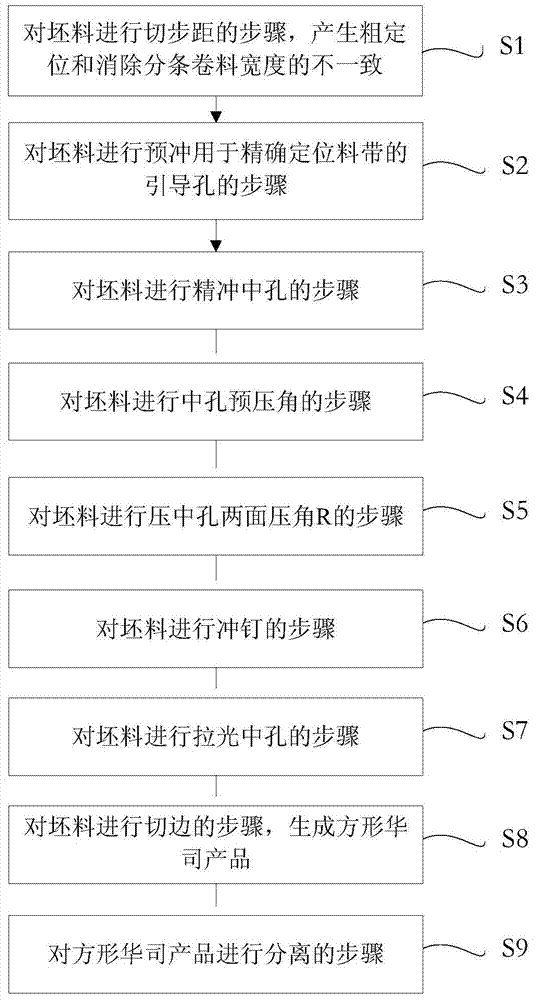

[0018] refer to Figure 2 ~ Figure 4 As shown, a square washer continuous mold production process provided by the present invention, the process includes the following steps using a continuous mold, S1 the step of cutting the blank to produce rough positioning and eliminate the inconsistency of the strip coil width; S2 is the step of pre-punching the blank to accurately locate the guide hole of the strip; S3 is the step of fine-punching the center hole on the blank; S4 is the step of pre-pressing the center hole on the blank; S5 is pressing the center hole on both sides of the blank The step of corner R; S6 the step of punching the blank; S7 the step of pulling the center hole of the blank; S8 the step of cutting the edge of the blank to generate a square washer product; S9 the step of separating the square washer product and in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com