Shaping mechanism of motor shell

A technology of a motor casing and a tapered surface is applied to the field of the shaping mechanism of the motor casing, which can solve the problems of inability to adjust the size of the shaping cavity, inconvenient use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

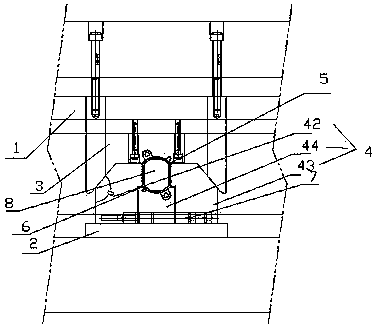

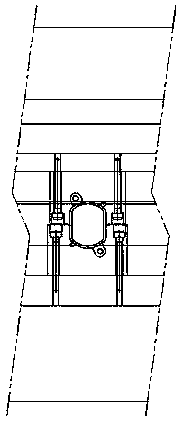

[0011] The present invention will be further described below in conjunction with accompanying drawing.

[0012] As shown in the figure, in order to solve the above-mentioned technical problems, a shaping mechanism of a motor housing in the present invention includes an upper mold base 1 and a lower mold base 2, and an upper template 3 is fixed on the upper mold base 1 by bolts or other means , The lower mold base 2 is provided with a lower template 4 matched with the upper template 3; the lower end surface of the upper template 3 is provided with a tapered groove 31, and the upper end surface of the lower template 4 is a tapered surface 41. During shaping, the tapered groove 31 matches the tapered surface 41; the bottom surface of the tapered groove 31 of the upper template 3 is provided with an upper shaping cavity 5, and the lower template 4 includes a first lower Template 42, second lower template 43, positioning block 44, the first and second lower templates 42, 43 are sym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com