Improved assistant brake structure applicable to Shanghai Volkswagen Santana driving school cars

A sub-brake, improved technology, applied in the field of sub-brake structure, can solve the problems of removing the fuel tank and increasing the workload, and achieves the effects of high safety, good effect and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

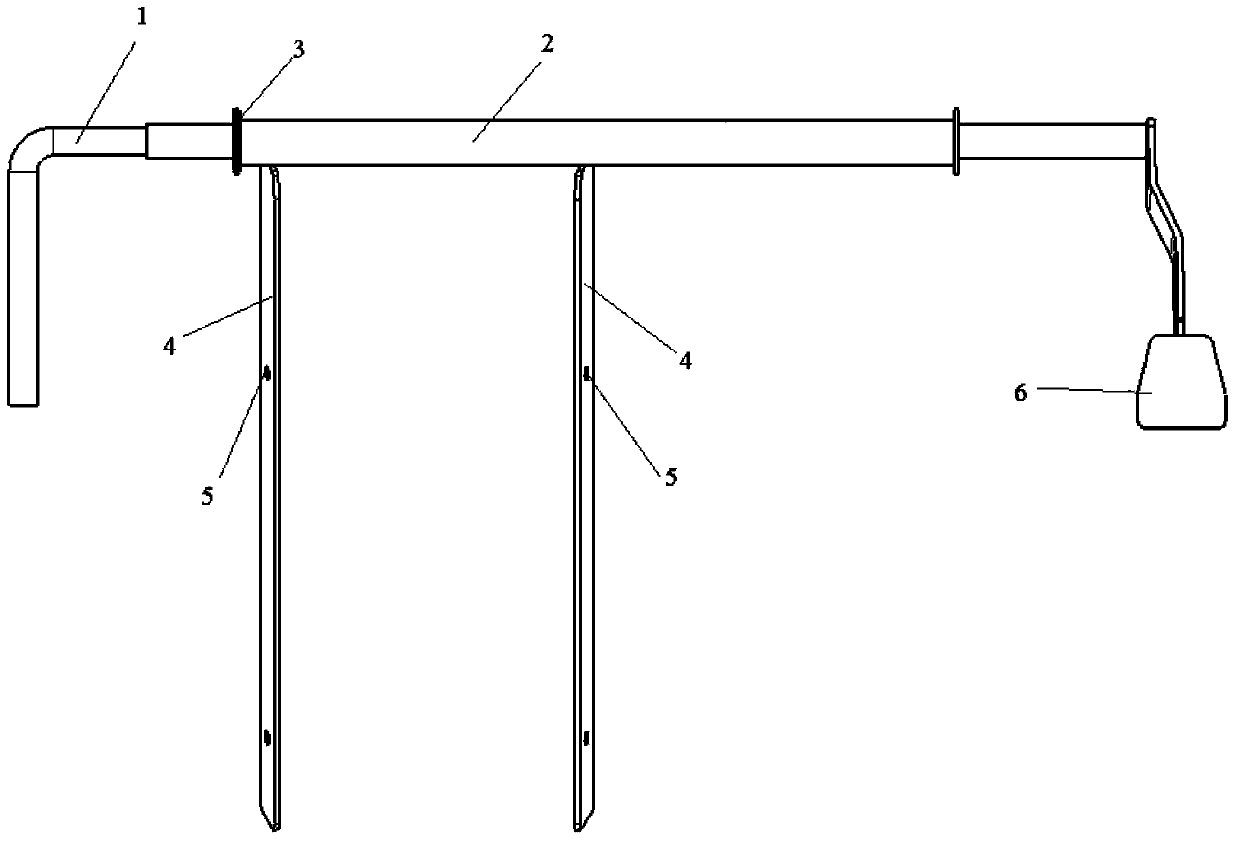

[0015] Such as figure 1 As shown, an improved secondary brake structure suitable for the driving school bus of Shanghai Volkswagen Santana includes brakes, a main steel pipe 1 and a secondary brake pedal 6 arranged on the passenger seat, one end of the main steel pipe 1 is connected to the brake, and the other end is connected to the secondary brake pedal. Brake pedal 6, an outer steel ring 2 is sleeved on the main steel pipe 1, the two ends of the outer steel ring 2 are provided with a limit collar 3, the outer steel ring 2 is restricted from moving left and right by the limit collar 3, and the outer steel ring Ring 2 is provided with two fixed inserts 4, the spacing between the two inserts matches the central channel of the car body, and the whole secondary brake structure is fixed on the vehicle body by the positioning holes on the inserts. The fixed insert 4 is provided with four positioning holes 5, two on each insert, which are detachably connected to both sides of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com