Construction method for filling and building subgrade by using silty-fine sand as filling materials

A construction method and technology of silt and fine sand, applied in roads, roads, buildings, etc., can solve problems such as failure to meet compaction standards, achieve engineering construction quality assurance, meet the requirements of design and technical specifications, and ensure construction schedule requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Note: The technical terms involved in this application, such as: A group, B group filler, improved soil, foundation coefficient K30, etc., all come from the industry standard of the People's Republic of China "Code for Design of Railway Subgrade" (TB 10001—2005 / J 447— 2005), and the entire construction and acceptance standards are also implemented with reference to this standard and related industry standards.

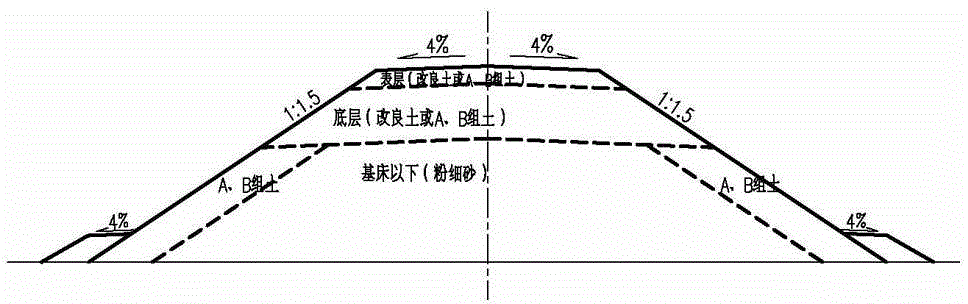

[0042] 1) The subgrade bed part shall be filled with improved soil according to the conventional filling method.

[0043] 2) Groups A and B of fillers are used below the foundation bed to wrap the edges. Specifically, the two sides of the road base are filled with fillers of groups A and B with a horizontal width of 2.0m, and the middle is filled with fine sand. Track-type bulldozers for compaction.

[0044] Emphasis in the present invention is below the foundation bed silty fine sand filling construction, introduce silty fine sand direct filling construction m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com