Methods and apparatus to assemble actuators

A technology of biasing device and compression device, applied in the direction of valve operation/release device, valve device, engine element, etc., can solve the problems of small space length, complexity, increase the space packaging of the actuator, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

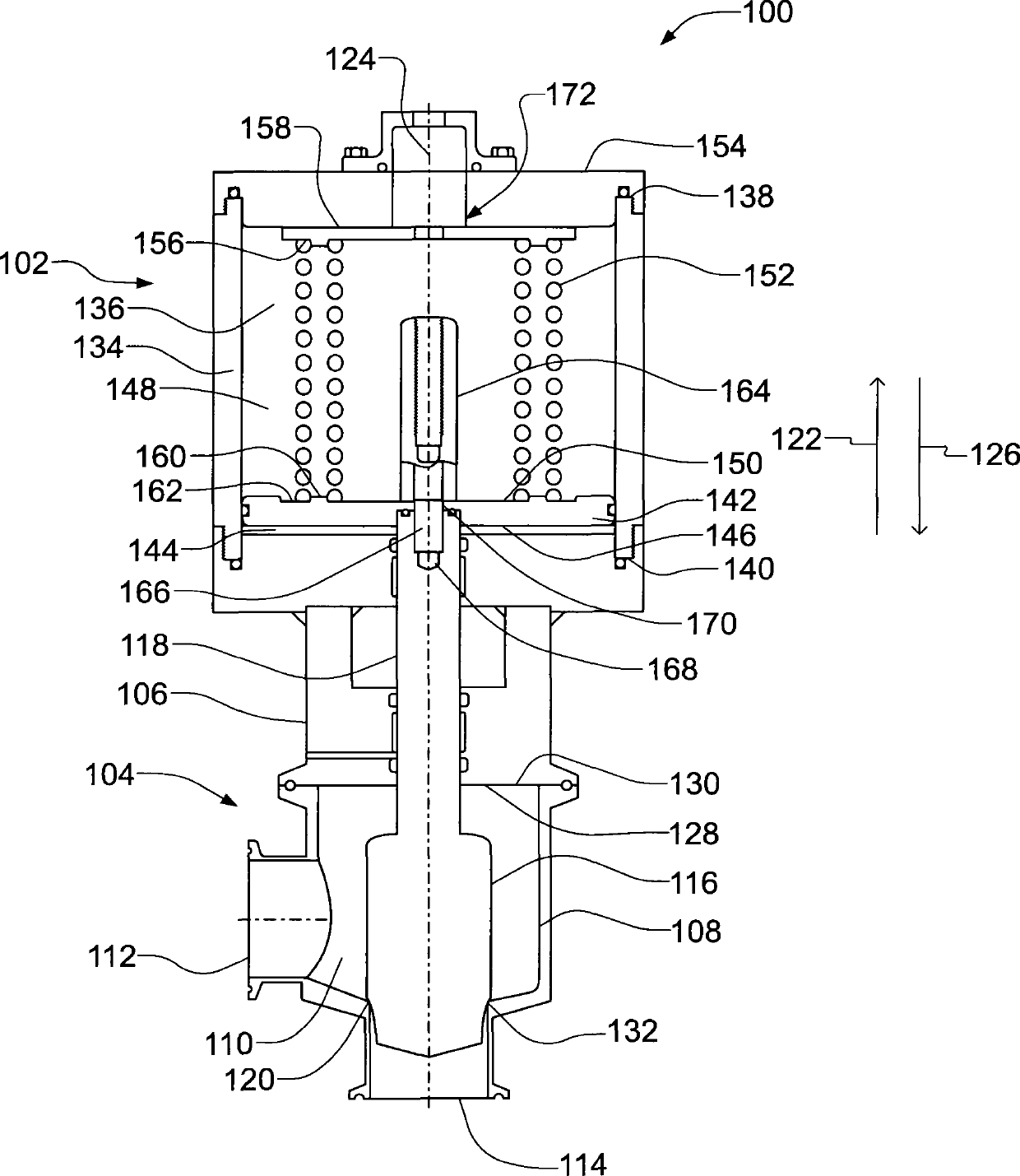

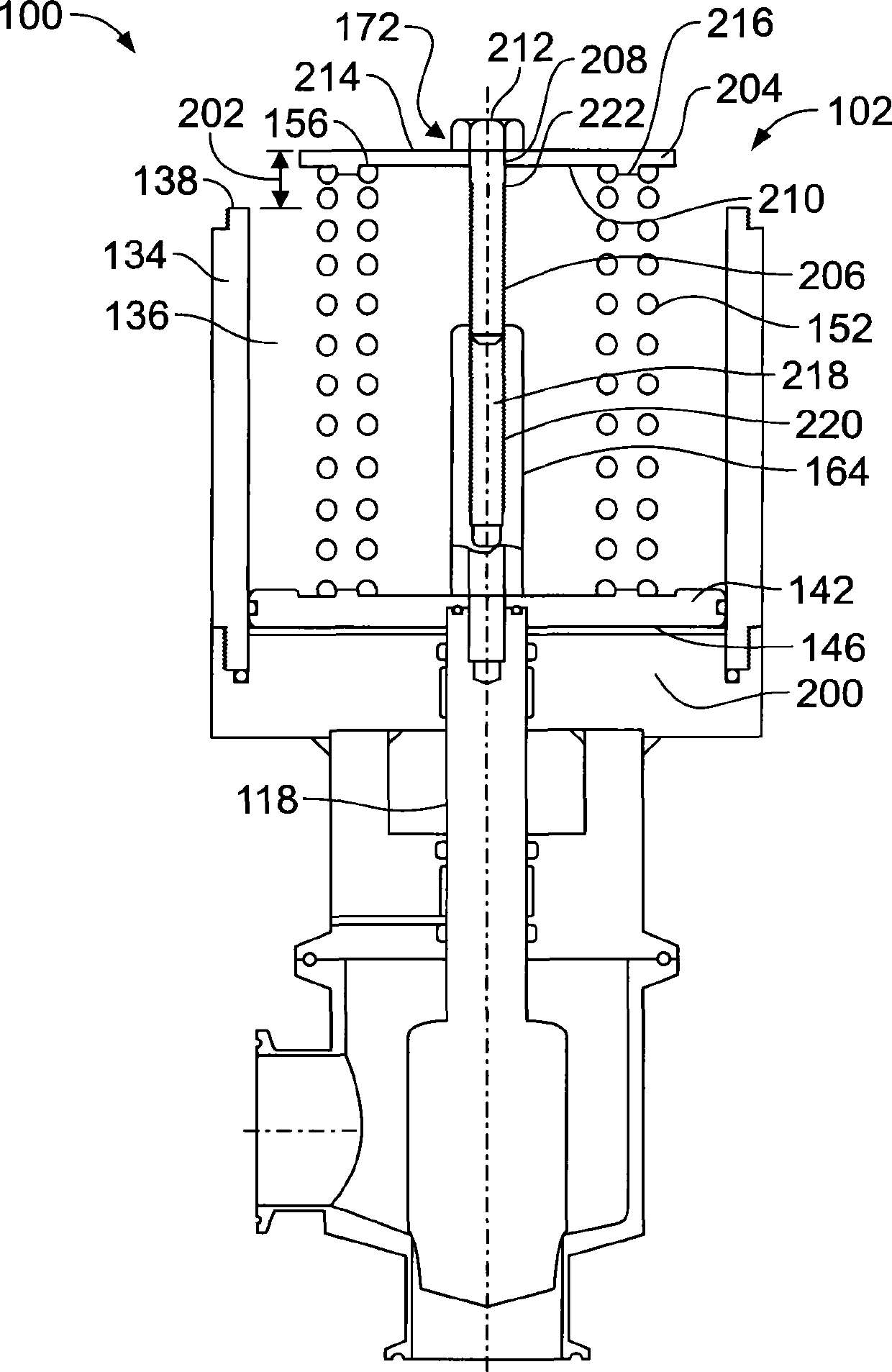

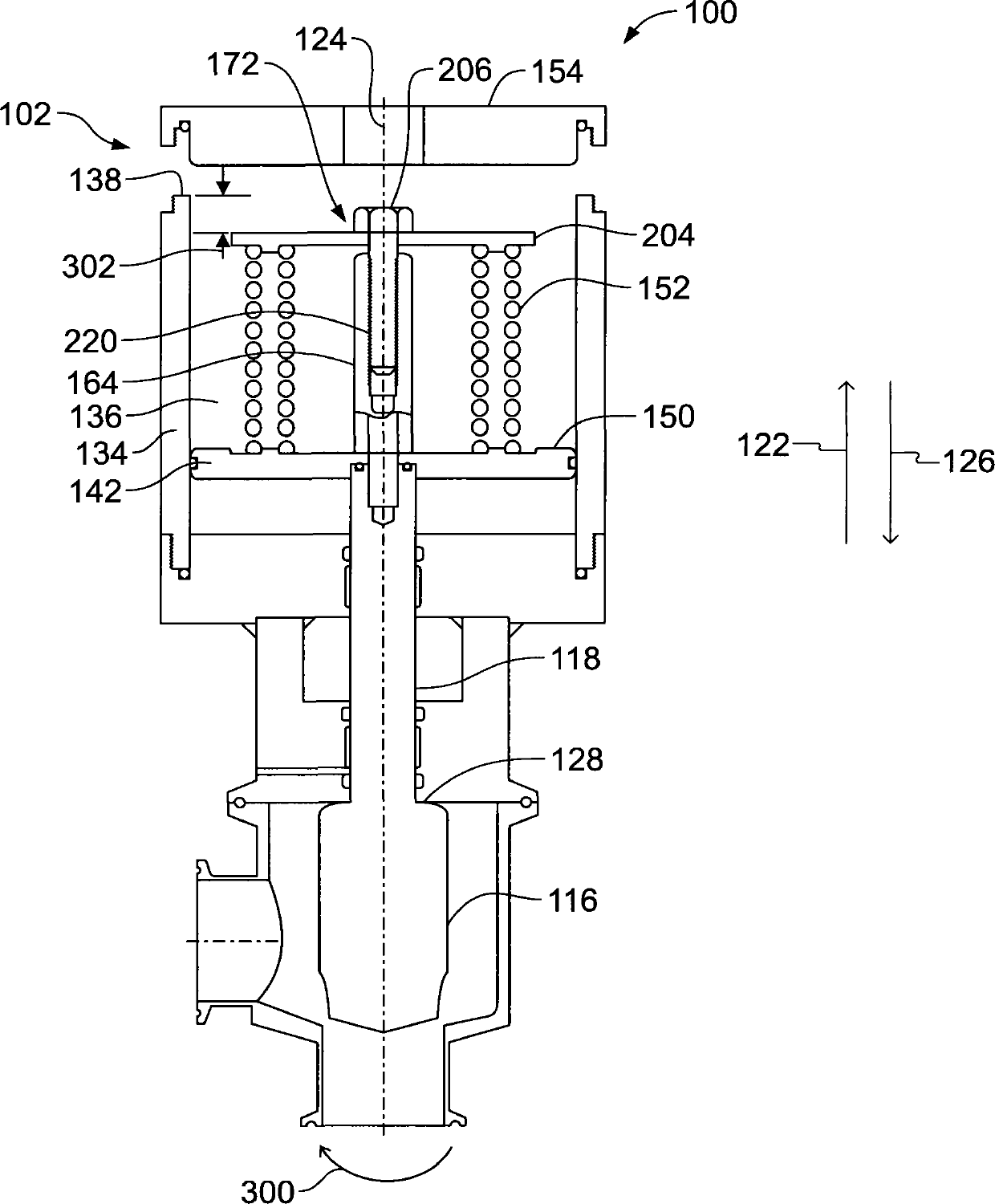

[0014] Some known actuators (eg, spring-return actuators) provide a mechanical fail-safe return. For example, in order to provide a mechanical fail-safe reset, these known actuators use a spring which is arranged in the cylinder of the actuator and directly contacts the loading part of the actuator (eg a diaphragm or piston). The spring urges the loading member to one end of the stroke path (eg, a fully open position or a fully closed position) when the control fluid supply to the actuator is deactivated and / or removed.

[0015] To facilitate the assembly of actuators using spring-return devices, cylinders are often provided with a spatial profile (e.g., length or height) that accommodates a chamber located in the cylinder when the spring is in the released or uncompressed state ( For example, a spring completely within it). In this way, the spring does not exert a large force on the cover when the cover is connected to the cylinder.

[0016] However, in some applications (e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com