A non-destructive flaw detection system for pipeline welds

A non-destructive flaw detection and pipeline technology, which is applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of X-ray flaw detectors easy to trip, low work efficiency, etc., to solve the problem of low detection efficiency, improve work efficiency, and improve the degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

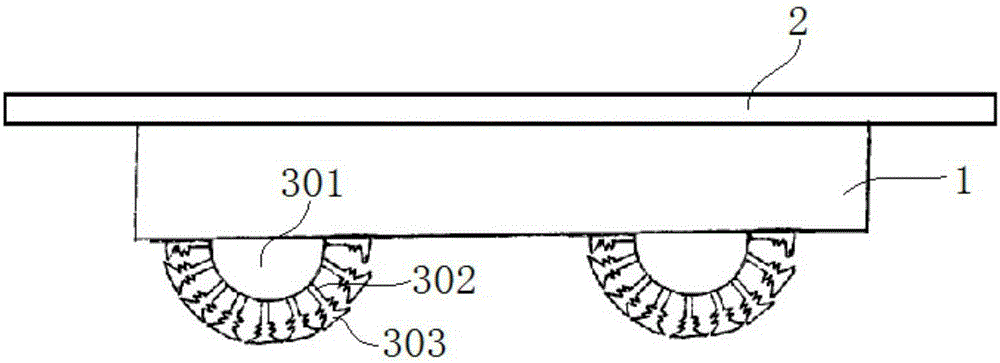

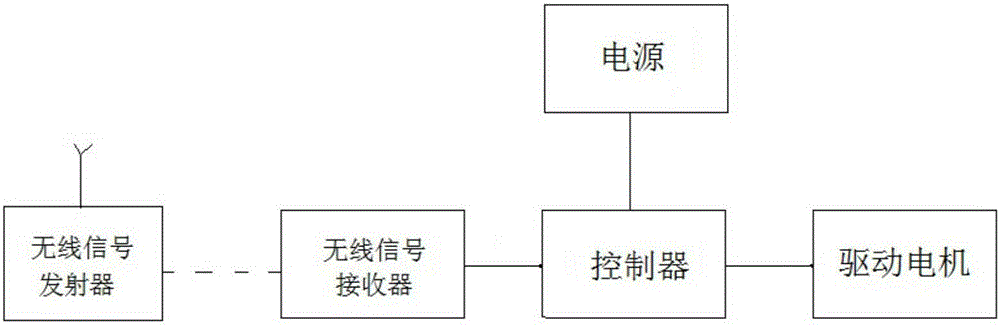

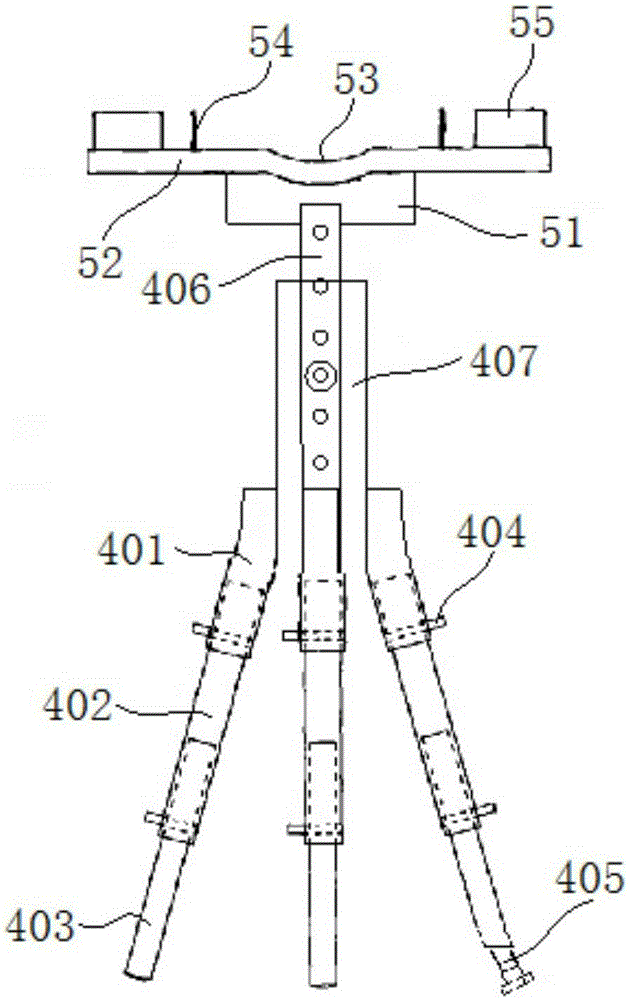

[0025] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 , a non-destructive flaw detection system for pipeline welds in this embodiment is composed of a carrying system, a support system, a space position adjustment system, and a flaw detector carrying system. The carrier system in this embodiment includes a carrier vehicle 1, a carrier platform 2, a driving wheel 301, a suction cup cylinder 302, a suction cup 303 and a carrier vehicle control mechanism, and the bottom of the carrier vehicle 1 is provided with four driving wheels 301, the The outer circumference of the driving wheel 301 is provided with a suction cup cylinder 302 perpendicular to the outer contour of the driving wheel 301, the other end of the suction cup cylinder 302 is fixedly connected with a suction cup 303, and the top of the vehicle 1 is provided with a carrying platform 2, The upper surface of the carrying platform 2 is a rectangular plane (such as figure 1 As shown), i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap