Self-driven tool box running on rail

A toolbox and self-driven technology, applied in the direction of manufacturing tools, workshop equipment, etc., can solve problems such as lack of time to replenish tools, waste of manpower, and affect work efficiency, so as to speed up work efficiency and work quality, save manpower and material resources, and structure well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

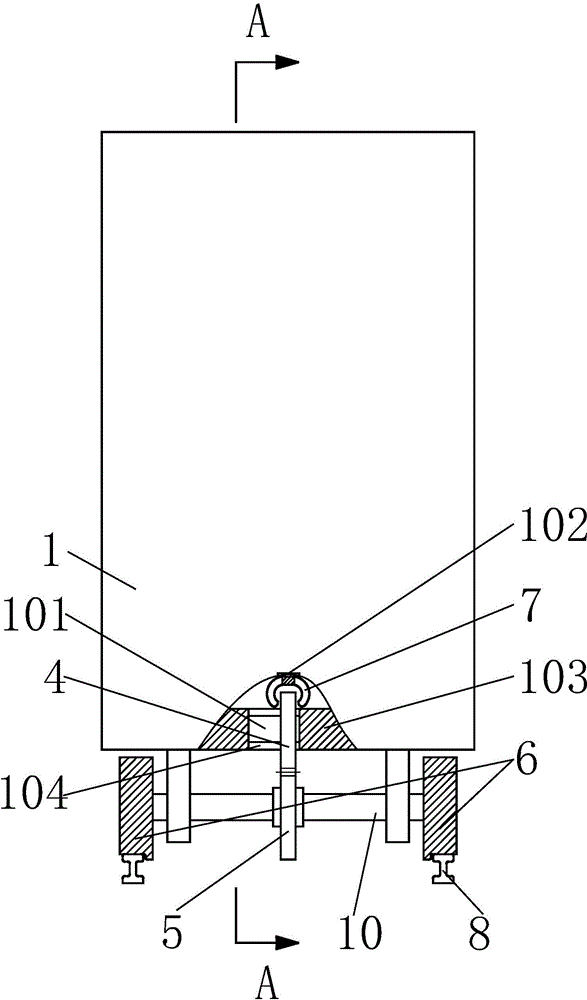

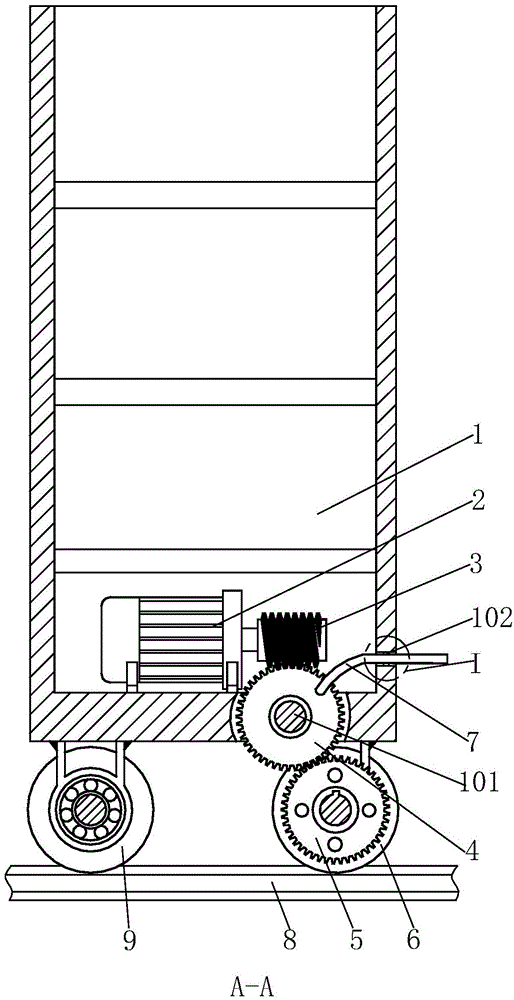

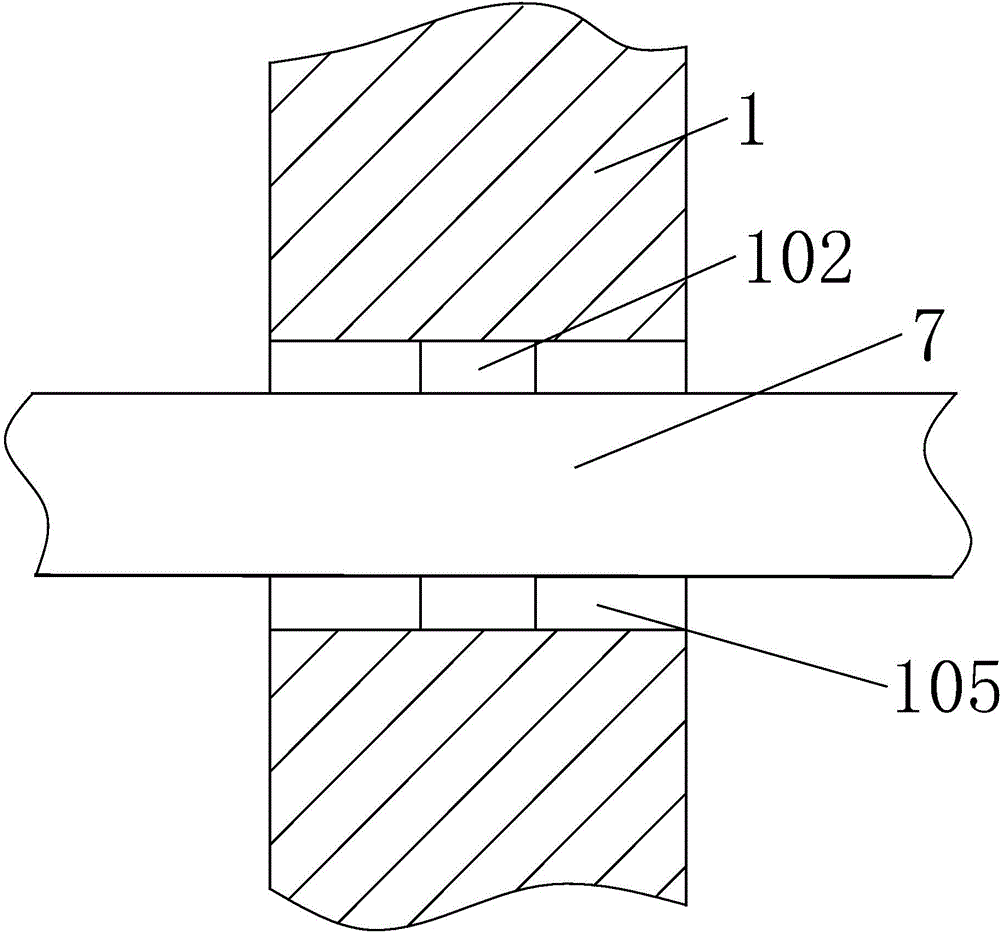

[0020] Such as Figure 1 to Figure 6 As shown, a self-driving tracking toolbox includes a toolbox 1, a motor 2 is fixed at the lower part of the toolbox 1; a worm 3 is installed on the shaft of the motor 2; the bottom of the toolbox 1 is provided The bottom plate 103; the front of the bottom plate 103 is provided with a No. 1 through hole 104; the No. 1 through hole 104 is fixed with a worm gear shaft 101; the worm gear shaft 101 is sleeved with a worm wheel 4 that matches the worm 3; Four wheels are installed on the bottom surface of the bottom plate 103. According to the installation positions of the four wheels, the wheels can be divided into a front wheel 6 and a rear wheel 9, and both are a pair; the front wheel 6 and the rear wheel 9 are b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com