Method for adjusting axial endplay gap of closed main reducer driving gear

A gap adjustment method and axial movement technology, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problems of difficult installation of active bevel gears, out-of-tolerance starting torque of main teeth, and shaft bearing shafts of main teeth. It is difficult to adjust to the movement gap, etc., so as to achieve the effect of convenient and quick adjustment, avoiding early damage and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

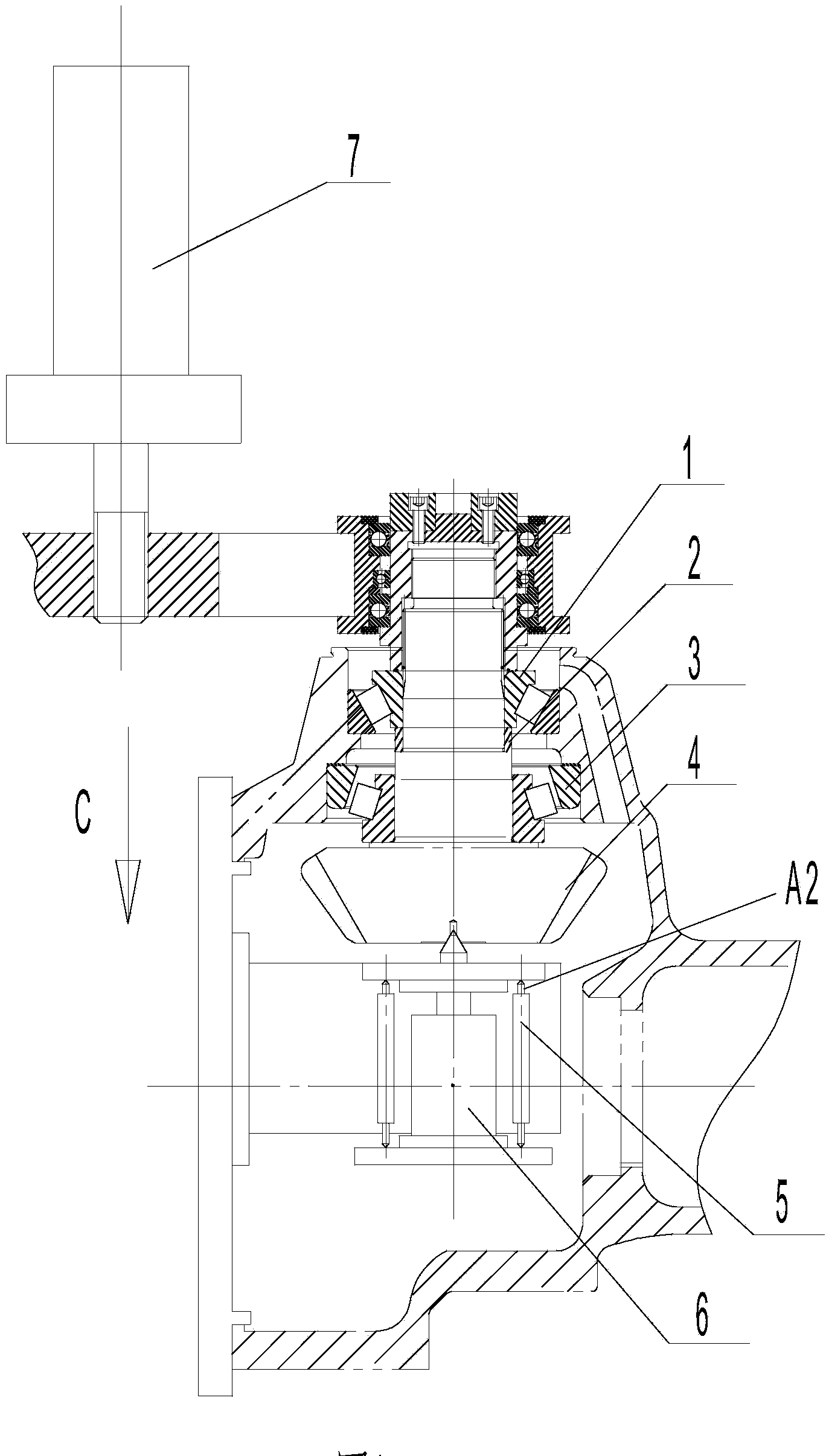

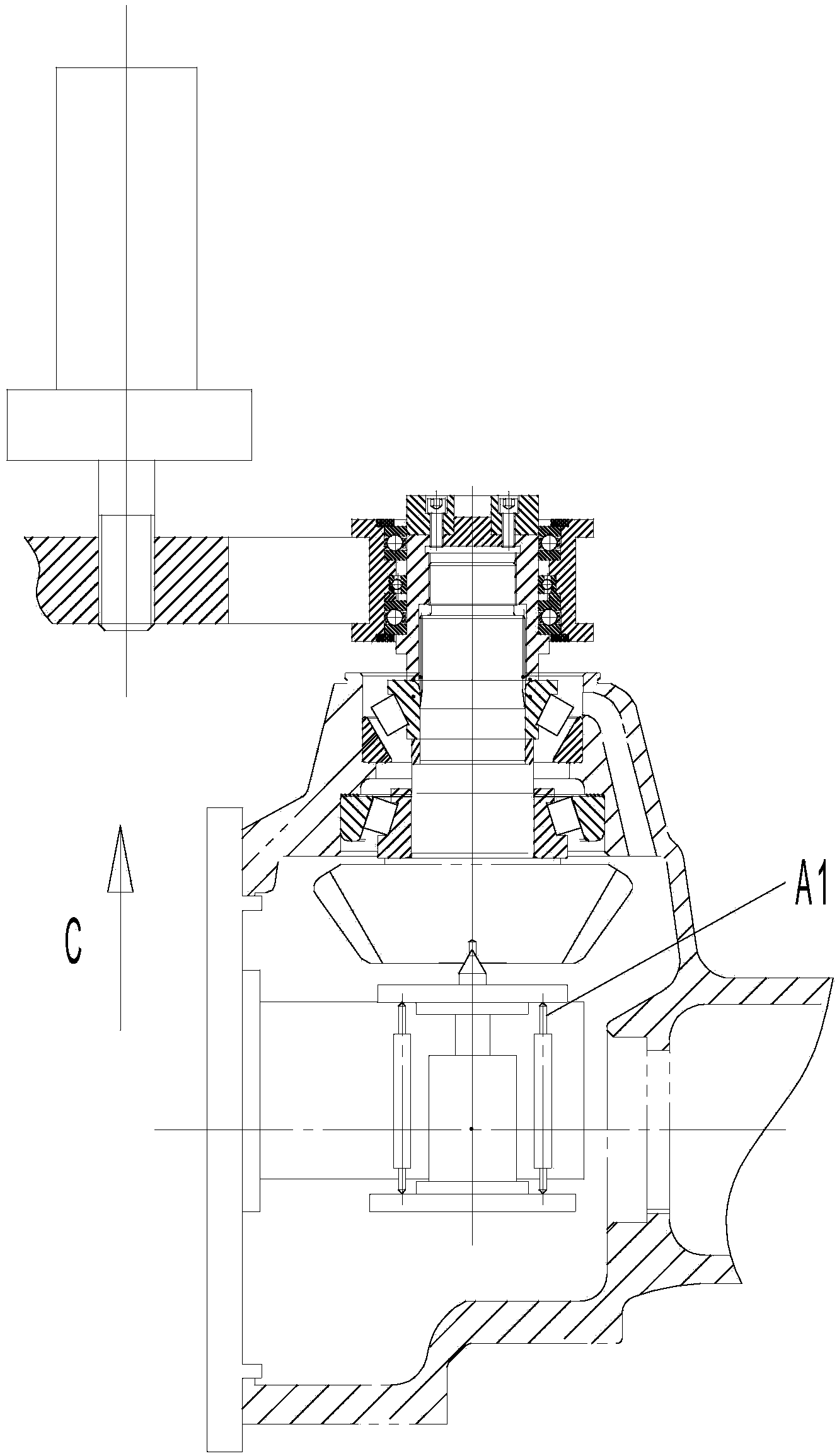

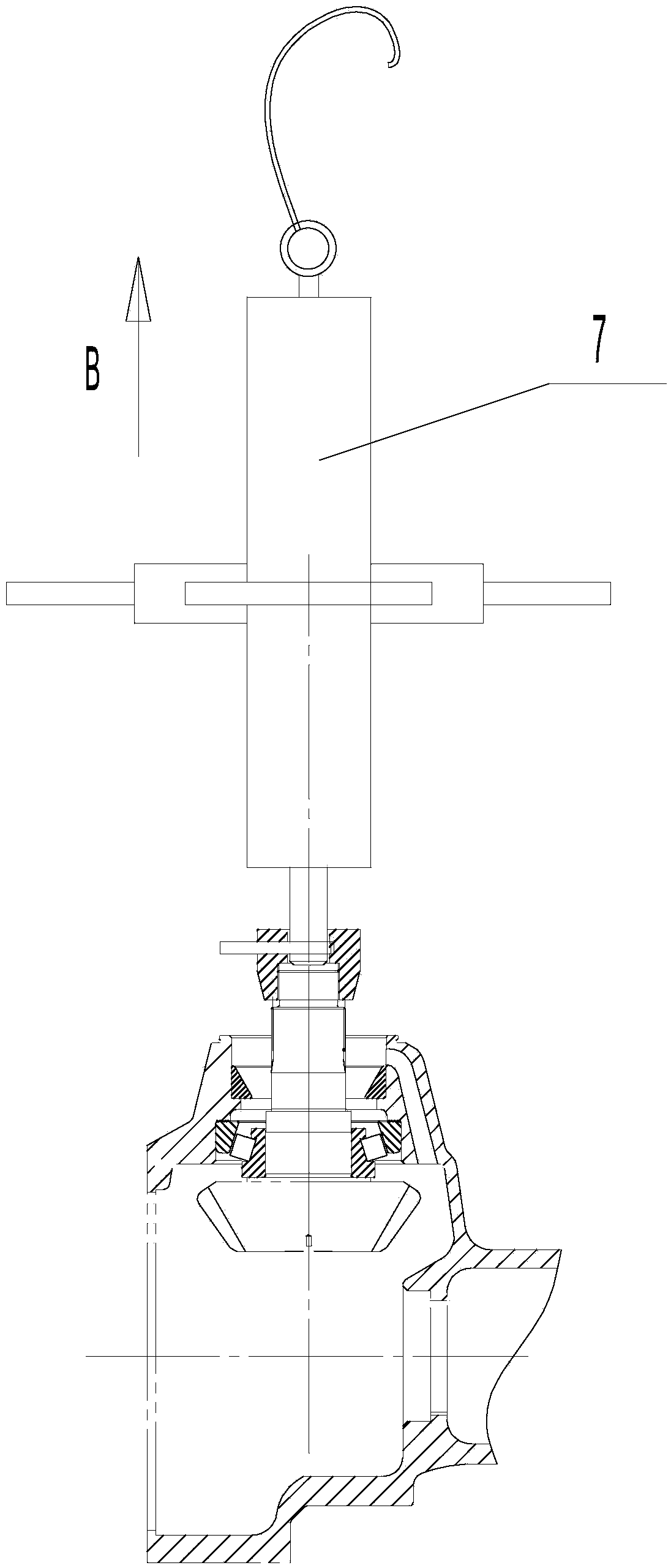

[0044] A method for adjusting the axial movement clearance of closed main and subtractive main teeth. The method is to press-fit the outer rings of the inner and outer bearings of the active bevel gear and the inner rings of the inner bearings respectively, and then pre-install the inner and outer bearings. A standard gasket; press-fit the inner ring of the outer bearing, push the driving bevel gear to move up and down, measure the displacement of the driving bevel gear moving up and down, and calculate the adjustment pad based on the displacement of the driving bevel gear moving up and down and the thickness of the standard gasket Replace the standard gasket with the adjusting gasket, pull the driving bevel gear to fit in place, install the inner ring and flange of the outer bearing, and check whether the starting force is qualified.

[0045] The method for adjusting the axial movement clearance of the closed main and subtractive main teeth includes the following steps:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com