Vehicle roof structure and vehicle

A vehicle roof and canopy technology, which is applied in the direction of freight vehicles, motor vehicles, load coverage, etc., can solve the problems of distortion, large deformation, and uneven stress on the roof, and achieve the requirements of reducing rigidity and reducing Position requirements, the effect of reducing vehicle weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

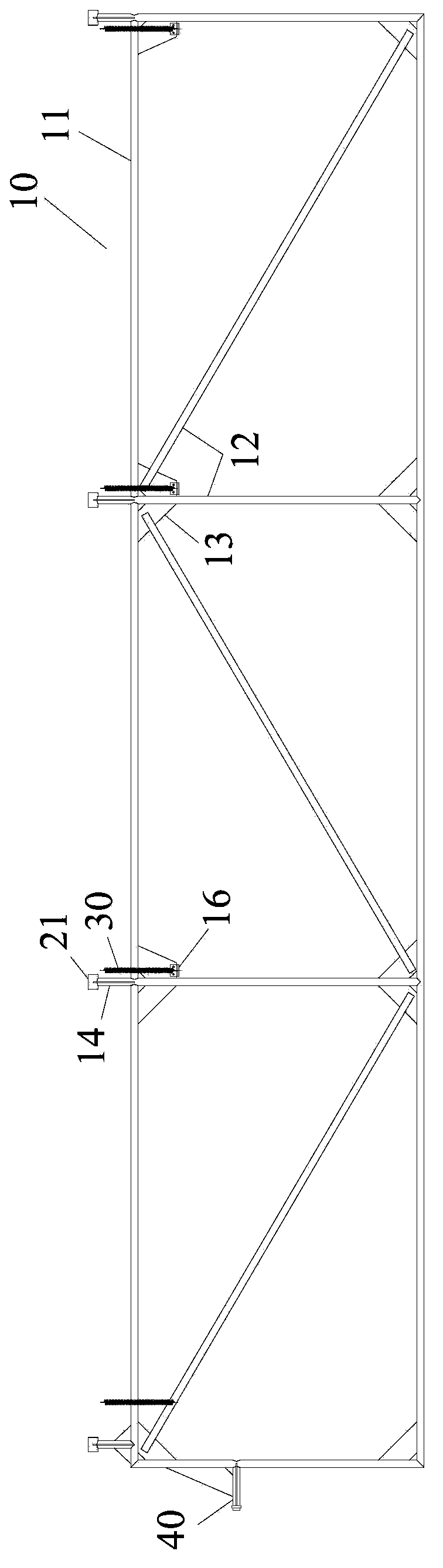

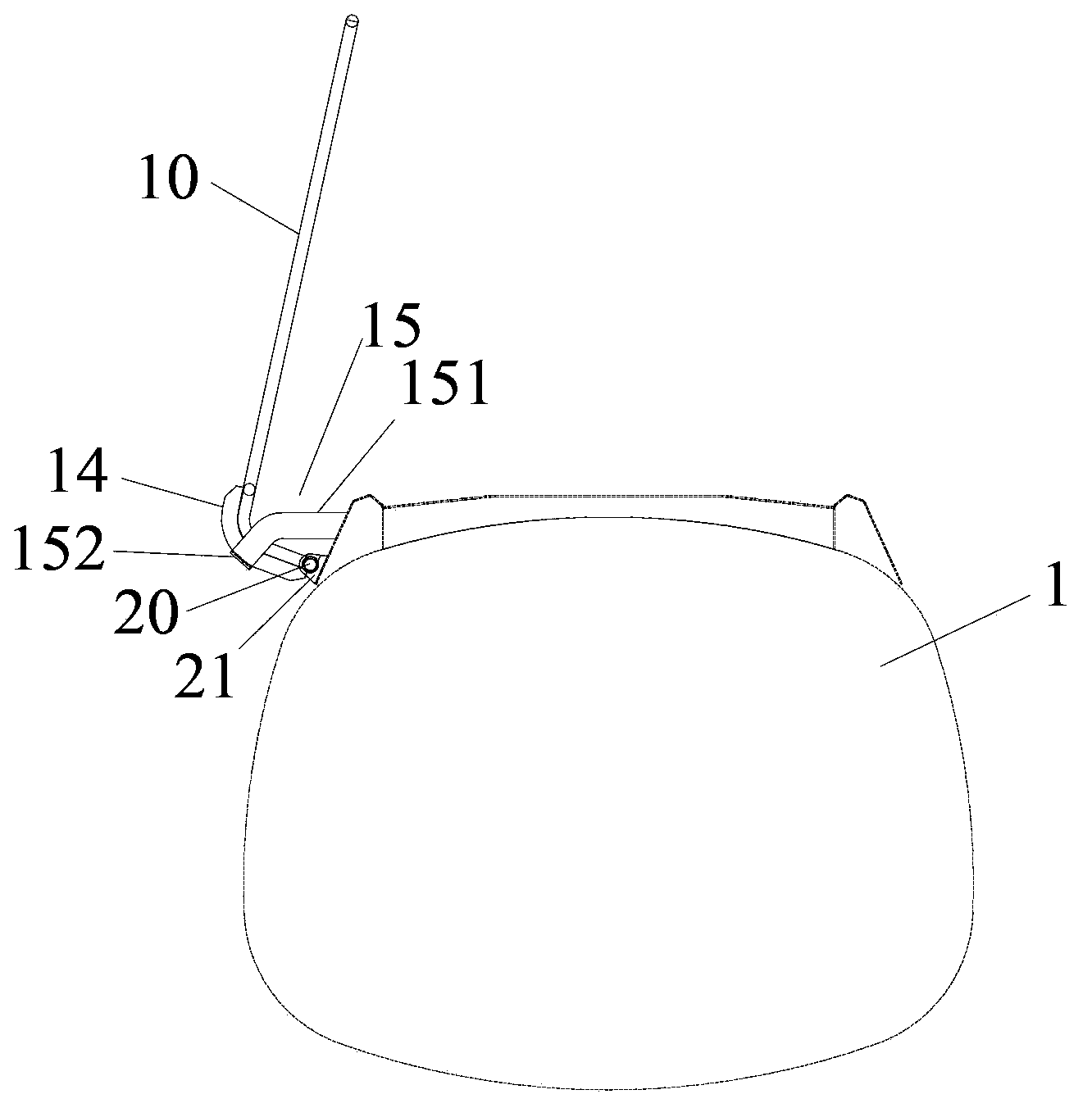

[0027] like figure 1 , 2 As shown, the roof structure of this embodiment includes a roof 10, a rotating shaft 20 and elastic elements. The canopy 10 covers the opening at the top of the box body 1 and is rotatably mounted on one side of the box body 1 through a rotating shaft 20 . The canopy 10 turns around the box body 1 to cover or open the opening. The roof 10 includes a roof frame surrounded by four frames 11 and a plurality of roof rods 12 whose two ends are respectively connected to the roof frame, and a plurality of ribs 13 fixedly connected to the ends of the roof rods 12 and the roof frame . A plurality of canopy rods 12 are arranged in the four frames 11 in a certain layout, so as to support the upper cloth or net (not shown) to form a canopy and cover the top of the box body 1 . The ribs 13 can connect the canopy pole 12 and the adjacent frame 11 to improve the strength of the canopy. The canopy 10 is similar to the prior art, so it will not be repeated here.

...

Embodiment 2

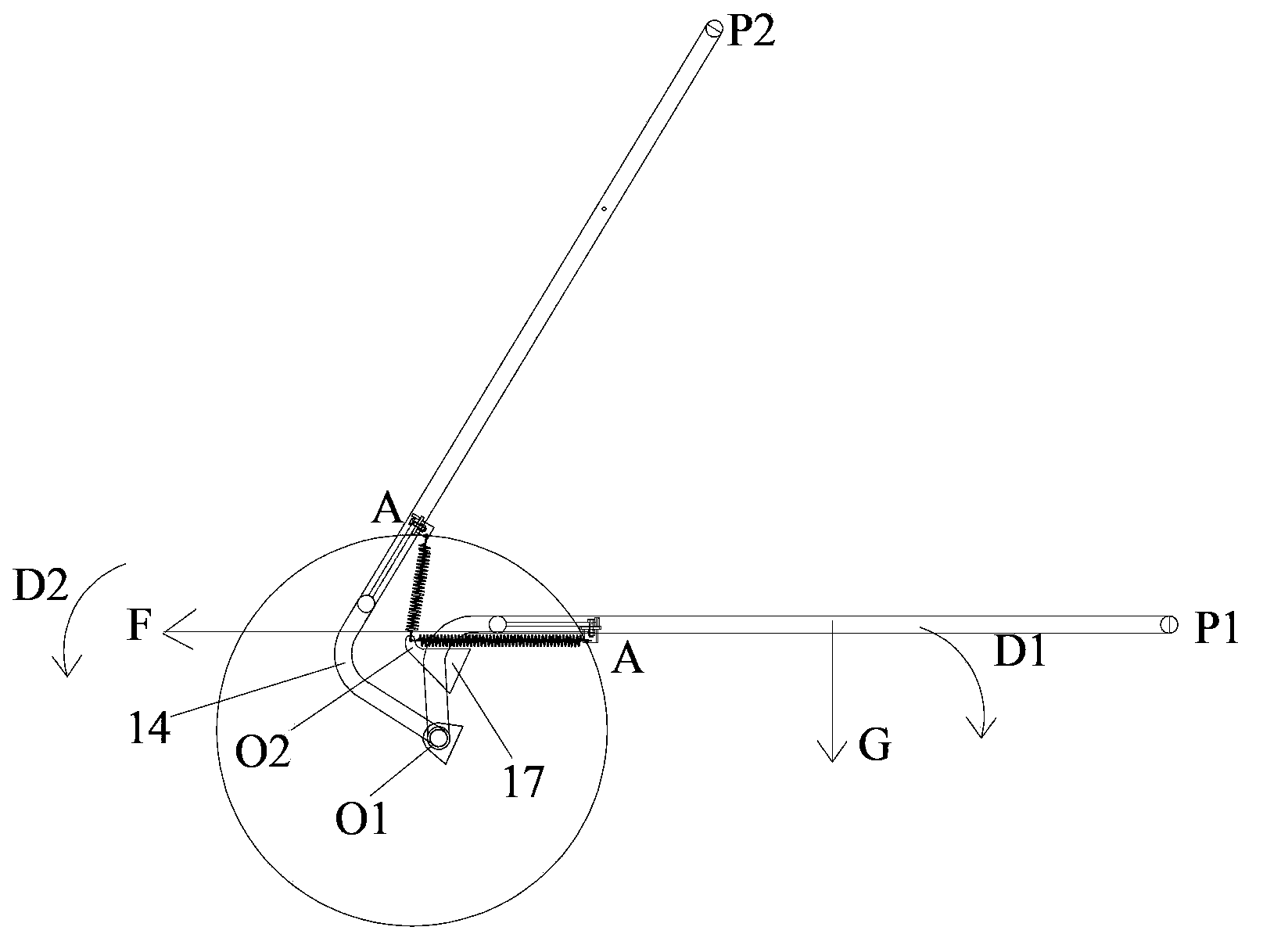

[0035] like Figure 4 As shown, the telescopic spring is a compression spring, the second mounting seat 17 is located on one side of the top of the box body, and the second mounting hole is located below the rotating shaft 22 . In the closed state, the compression spring 30 is in a compressed state with a certain amount of compression. At this time, the direction of the moment generated by the compression spring 30 is D2 (counterclockwise), and the direction of the moment D1 (clockwise) generated by the gravity of the canopy, that is, the directions of the two moments are opposite, so that the canopy is opened with less effort. In the fully opened state of the roof, the compression spring 30 is in a free state or in a compressed state, and the compression amount at this time is 0, or less than that in the compressed state. During the entire overturning process, the direction of the moment generated by the compression spring 30 is always opposite to the direction of the moment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com