Device and method for hindering sucked vortex of aircraft fuel pump

A suppressing device and fuel pump technology, applied in parts, pumps, pump elements, etc. of pumping devices for elastic fluids, can solve the problem of not being able to continuously provide fuel that meets the vapor-liquid ratio and pressure requirements, reducing the fuel pump and fuel system Reliability, damage to the surface and structure of wetted parts, etc., to improve aircraft economy, reduce unusable fuel, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

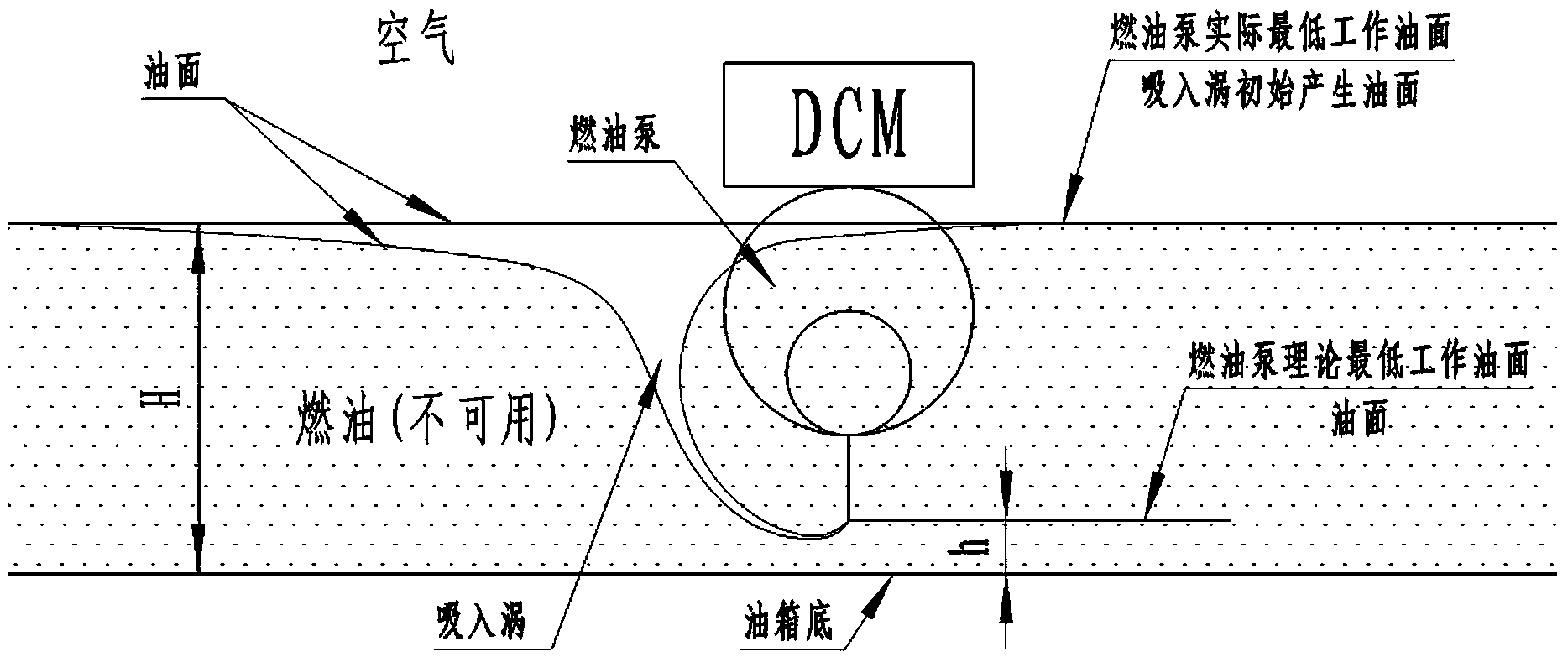

[0016] See the specific implementation Figure 1 to Figure 4 . The present invention will be further described in detail through specific embodiments below.

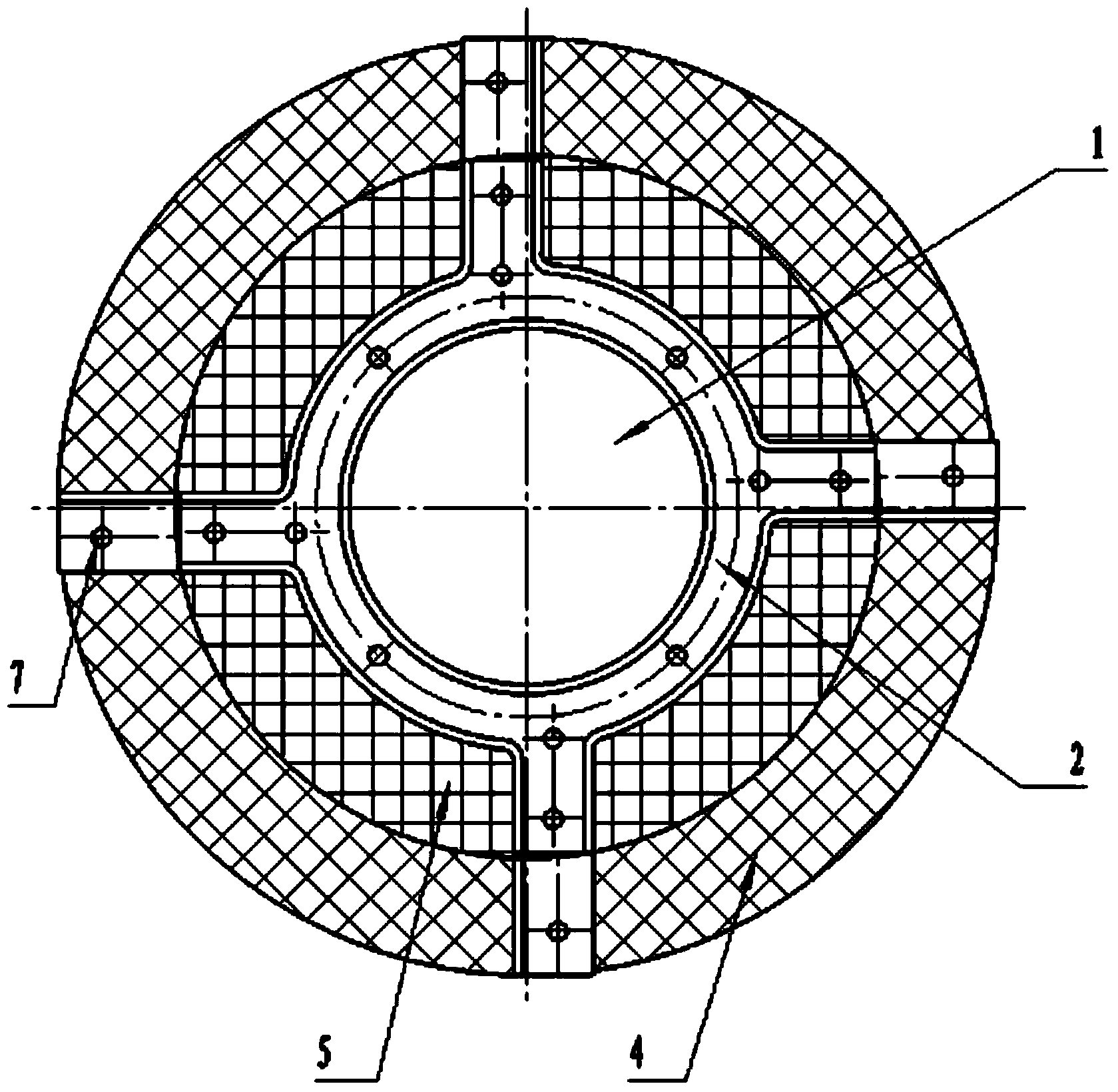

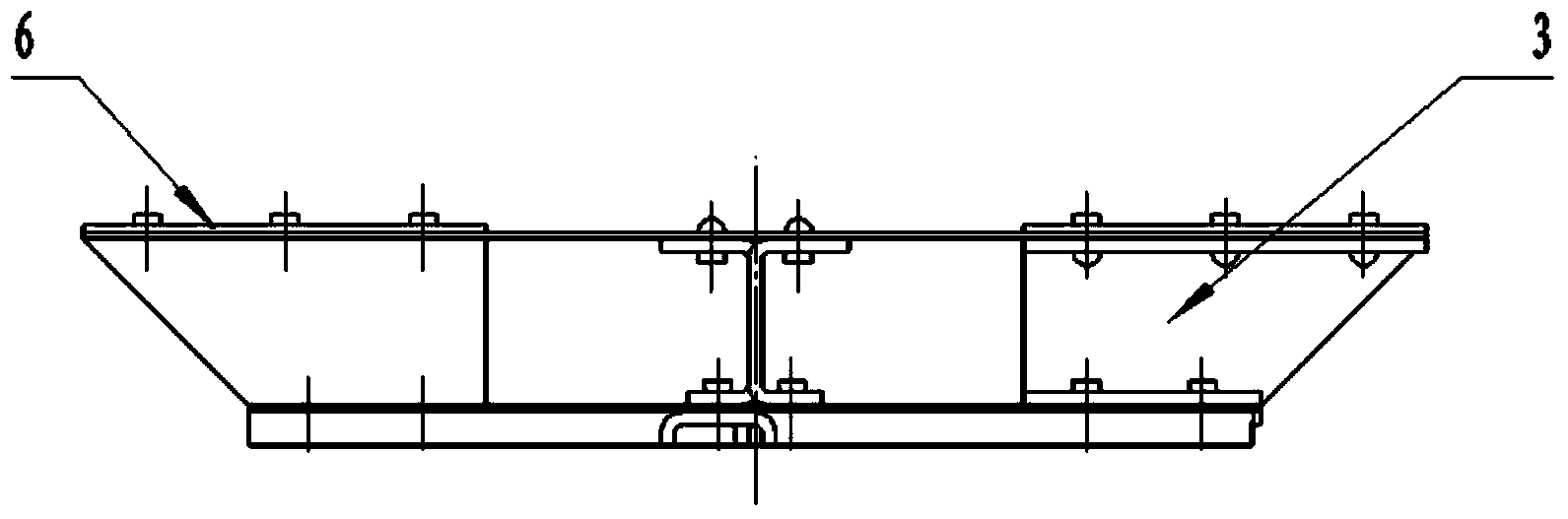

[0017] like figure 1 and figure 2 As shown, an aircraft fuel pump suction vortex suppression device is provided with a through hole 1 for inserting the fuel pump in the middle, a mounting bracket 2 and more than three supporting ribs 3 constitute the installation structure of the device, and on the top of the installation structure A layer of ring-shaped upper net 4 is laid, and a ring-shaped lower net 5 is laid under the installation structure. The upper net 4 is fixed by side strips 6 and rivets 7. The upper net 4 and lower net 5 form a damping net, and more than three supporting ribs 3 form a radiation shaped damping ribs.

[0018] The supporting rib 3 is a thin-plate structural member, and its web has no holes or several small holes with a diameter less than 30mm.

[0019] The upper net 4 and the lower net 5 ar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap